A kind of preparation method of inorganic solid electrolyte membrane/electrode composite material

An inorganic electrolyte and inorganic solid technology, which is used in the manufacture of electrolyte batteries, electrolyte layer coatings, non-aqueous electrolyte batteries, etc., can solve the problems of unsuitability for continuous, large-scale production, low production efficiency, and high equipment requirements, and achieve film Good effect, uniform thickness, simple preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Synthesis of sulfide (Li 8 P 2 S 9 ) Inorganic solid electrolyte, according to P 2 S 5 : Li 2 Ratio of S=25:75 (molar ratio) Weigh raw materials, grind and mix in an argon glove box. Put the uniformly mixed raw materials into a quartz tube furnace for sintering to obtain Li 8 P 2 S 9 powder (such as figure 1 shown in a). The sintering temperature is 550°C, and the sintering time is 12h.

[0019] The second step: prepare electrolyte ink, weigh 1.5gLi 8 P 2 S 9 Powder, dissolve the powder in 5mL N,N-dimethylformamide dispersant, add 0.6g polyvinylidene fluoride binder, ultrasonic frequency 50KHz, ultrasonic time 8min, get the suspension and let it stand for 120min to get the upper layer uniformly dispersed Post-stabilized inks (such as figure 1 shown in b).

[0020] The third step: inkjet coating to prepare all-solid-state lithium-ion batteries, weigh a certain amount of electrolyte ink, add it to the printer ink cartridge, and print directly on the...

Embodiment 2

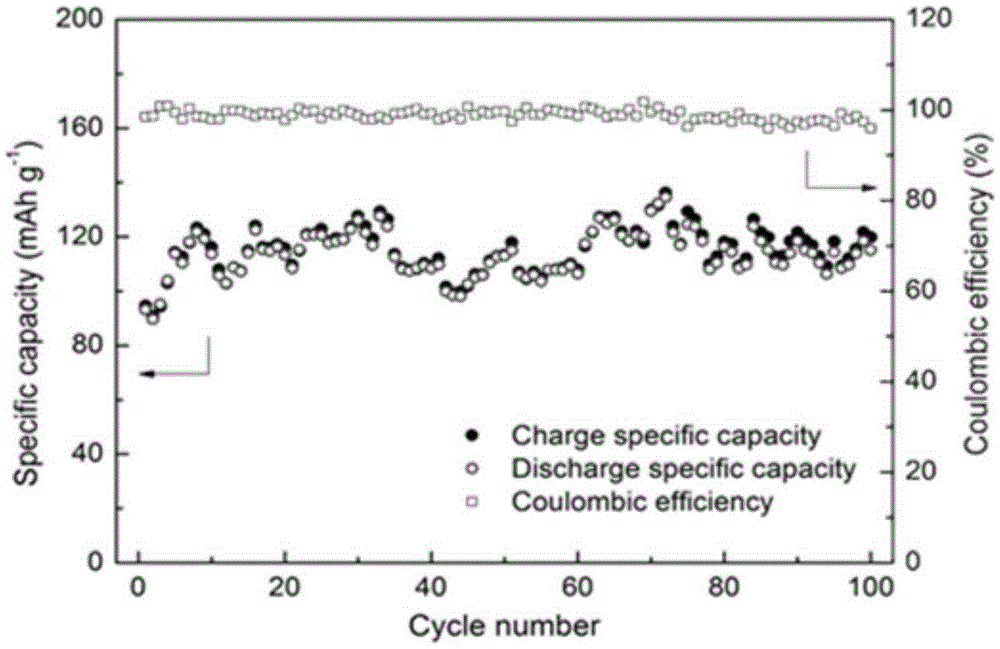

[0022] Use 6g of the same electrolyte powder as in Example 1, dissolve the powder in 3mL of tetrahydrofuran dispersant, add 0.2g of polyvinylidene fluoride binder, ultrasonic frequency 100KHz, ultrasonic time 10min, obtain a suspension and let it stand for 120min to obtain the upper layer Stable ink after even dispersion. pre-prepared with LiMn 2 o 4 As the active material, polyvinylidene fluoride is used as the binder of the positive electrode sheet. The electrolyte ink is sprayed on the positive electrode sheet, and the drying temperature is 100 ° C for 12 hours to obtain a dense and uniform electrolyte membrane with a thickness of about 60 μm. The electrolyte membrane / Electrode composite material, assembled into a button battery, after 100 cycles at 25°C and 1C, the charging specific capacity is 120mAhg -1 , the specific discharge capacity is 118mAhg -1 , Coulombic efficiency is 98.3%.

Embodiment 3

[0024] The first step: the inorganic solid electrolyte was synthesized by high-energy ball milling, and lithium sulfide and phosphorus sulfide were mixed according to the stoichiometric ratio in the glove box to control the Li 2 S:P 2 S 5 =3:1 molar ratio mixed, sealed into a ball mill jar full of argon atmosphere. Use a planetary ball mill for mixing. In order to obtain the best results, the large ball is used to counterweight and smash the sample and disperse the small ball. Agate balls of three sizes (d=10mm)×6 / grain and small (d=6mm)×20 / grain are used together, and 2g of sulfide powder material obtained by proportioning and weighing and agate balls of three different sizes are added into a ball mill for dry grinding. The ball milling parameters are set to a speed of 200rmin -1 , the ball milling time is 12h, and Li 8 P 2 S 9 powder.

[0025] Weigh 3g of the inorganic electrolyte powder, dissolve the powder in 3mL of anhydrous hydrazine dispersant, add 0.3g of polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com