Distillation drying tower for treating desulfurized waste water in thermal power plant

A technology for desulfurization wastewater and thermal power plants. It is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of high cost of chemical treatment, inability to remove chloride ions, and inability to recycle. , to reduce processing costs and equipment maintenance costs, improve dust removal effect, and save processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

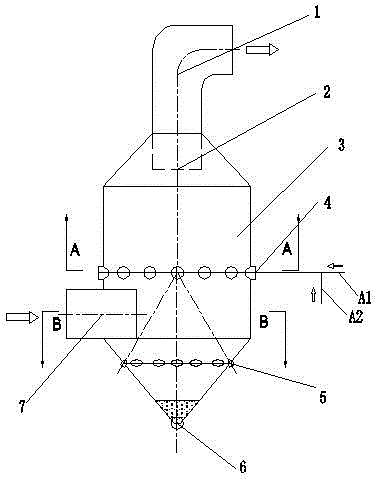

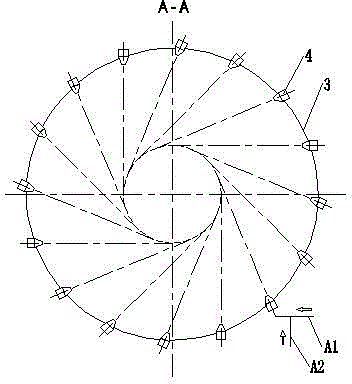

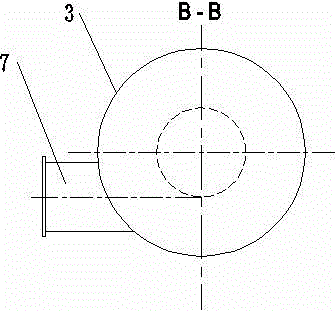

[0024] Embodiment 1: Treatment of thermal power plant desulfurization waste water evaporation tower, such as figure 1 As shown, it includes an outlet flue 1, a mechanical filter 2, an evaporation tower cylinder body 3, an atomizing nozzle 4, an air nozzle 5, a scraper slag remover 6, and an inlet flue 7. The waste water evaporation tower uses evaporation to dry Tower effect, for desulfurization wastewater or other wastewater with high salt content that is difficult to recycle, it is first atomized through the atomization nozzle, and then evaporated and solidified in the evaporation tower.

[0025] There is a flue gas outlet on the top of the evaporation tower body 3, the flue gas outlet shown is connected with an outlet flue 1, the bottom of the outlet flue 1 is located at the upper part of the evaporation tower body 3, and the bottom of the outlet flue 1 A mechanical filter 2 is arranged on the top, and the mechanical filter 2 can be types such as shutters, filter screens or ...

Embodiment 2

[0037] Embodiment 2: Considering the actual situation of flue arrangement in industries such as iron and steel, papermaking and coal gasification, it is possible to consider using the attached Figure 4 The desulfurization waste water evaporation tower structure shown in , the desulfurization waste water evaporation tower structure and the treatment thermal power plant desulfurization waste water evaporation tower structure in embodiment 1 have only the following differences:

[0038] 1. The bottom of the outlet flue 1 extends all the way to the cylinder body 3 of the evaporation tower, specifically the part between the atomizing nozzle 4 and the tuyere 5 in the cylinder body 3 of the evaporation tower. Under the action of gravity, the high-temperature flue gas entering the evaporation tower body 3 from the inlet flue 7 forces the airflow to descend, and because the bottom of the outlet flue 1 is located at the lower part of the evaporation tower body, under its draft and high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com