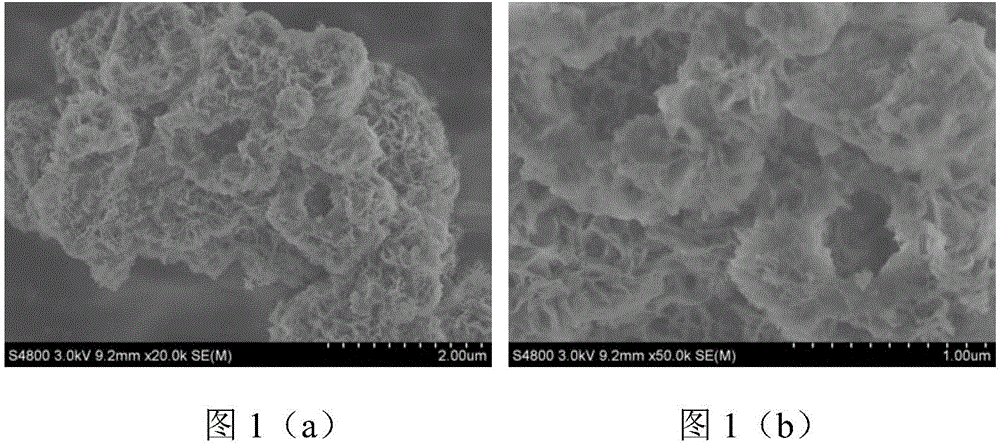

Preparation method of polyacrylic ester emulsion modified by hollow zinc oxide microspheres with shell layers adopting sheet structures

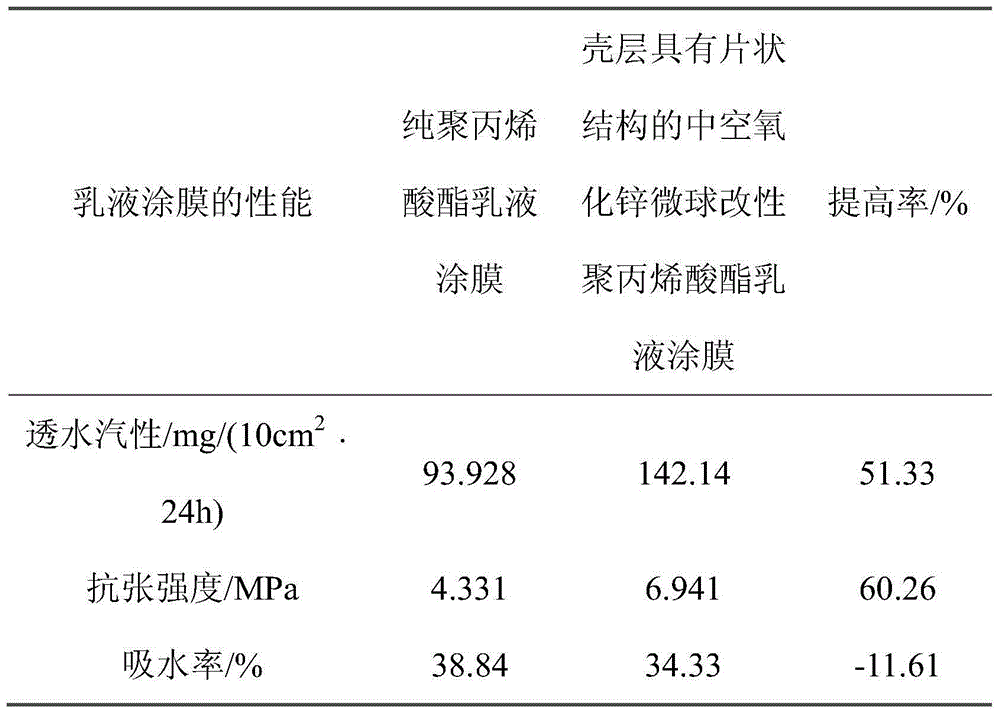

A technology of polyacrylate emulsion and sheet-like structure, applied in the direction of coating, can solve the problems of poor water resistance, poor friction and mechanical properties, etc., and achieve the effects of improved water resistance, low cost and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Add 2 / 3 of the amount of Zn(NO 3 ) 2 ·6H 2 O and hexamethylenetetramine were miscible in deionized water, and reacted at 81°C for 5 minutes, then added 2 / 3 of the amount of sodium citrate, kept the reaction for 1.1 h, and added the remaining 1 / 3 of the amount of Zn(NO 3 ) 2 ·6H 2 O and hexamethylenetetramine, and react at 86°C for 5 minutes, add the remaining 1 / 3 of the amount of sodium citrate, and react at 86°C for 10 minutes, use ammonia water to adjust the pH value to 9.4, and then at 86°C Under heat preservation for 3 hours, then washed with water and dried at 60°C for 12 hours to obtain hollow zinc oxide microspheres with a sheet-like structure in the shell; wherein, Zn(NO 3 ) 2 ·6H 2 The mass ratio of the total amount of O, hexamethylenetetramine, and sodium citrate is 0.891:0.42:0.111; Zn(NO 3 ) 2 ·6H 2 The mass ratio of the total mass of O to deionized water is 0.891:70.

[0023] 2) After ultrasonically dispersing the hollow zinc oxide microspheres...

Embodiment 2

[0025] 1) Add 2 / 3 of the amount of Zn(NO 3 ) 2 ·6H 2 O and hexamethylenetetramine were miscible in deionized water, and reacted at 82°C for 5 minutes, then added 2 / 3 of the amount of sodium citrate, kept the reaction for 1.2 hours, and added the remaining 1 / 3 of the amount of Zn(NO 3 ) 2 ·6H 2 O and hexamethylenetetramine, and react at 87°C for 5 minutes, add the remaining 1 / 3 of the amount of sodium citrate, and react at 87°C for 10 minutes, use ammonia water to adjust the pH value to 10, and then at 87°C Under heat preservation reaction for 3.5h, then washed with water and dried at 80°C for 8h to obtain hollow zinc oxide microspheres with a sheet-like structure in the shell; wherein, Zn(NO 3 ) 2 ·6H 2 The mass ratio of the total amount of O, hexamethylenetetramine, and sodium citrate is 0.7425:0.3495:0.093; Zn(NO 3 ) 2 ·6H 2 The mass ratio of the total mass of O to deionized water is 0.7425:70.

[0026] 2) After ultrasonically dispersing the hollow zinc oxide micro...

Embodiment 3

[0028] 1) Add 2 / 3 of the amount of Zn(NO 3 ) 2 ·6H 2 O and hexamethylenetetramine were miscible in deionized water, and reacted at 81°C for 5 minutes, then added 2 / 3 of the amount of sodium citrate, kept the reaction for 1.5 hours, and added the remaining 1 / 3 of the amount of Zn(NO 3 ) 2 ·6H 2O and hexamethylenetetramine, and react at 86°C for 5 minutes, add the remaining 1 / 3 of the amount of sodium citrate, and react at 86°C for 10 minutes, use ammonia water to adjust the pH value to 9.8, and then at 86°C Under heat preservation reaction for 4h, then washed with water and dried at 70°C for 10h to obtain hollow zinc oxide microspheres with a sheet-like structure in the shell; wherein, Zn(NO 3 ) 2 ·6H 2 The mass ratio of the total amount of O, hexamethylenetetramine, and sodium citrate is 1.2075: 0.5685: 0.2985; Zn(NO 3 ) 2 ·6H 2 The mass ratio of the total mass of O to deionized water is 1.2075:70.

[0029] 2) After ultrasonically dispersing the hollow zinc oxide mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com