Process for leaching copper oxide ore by alkaline bacterium

A copper oxide ore leaching technology, applied in the field of leaching mining, can solve the problems of poor permeability, high cost, high acid consumption, etc., and achieve the effect of low cost, small investment and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

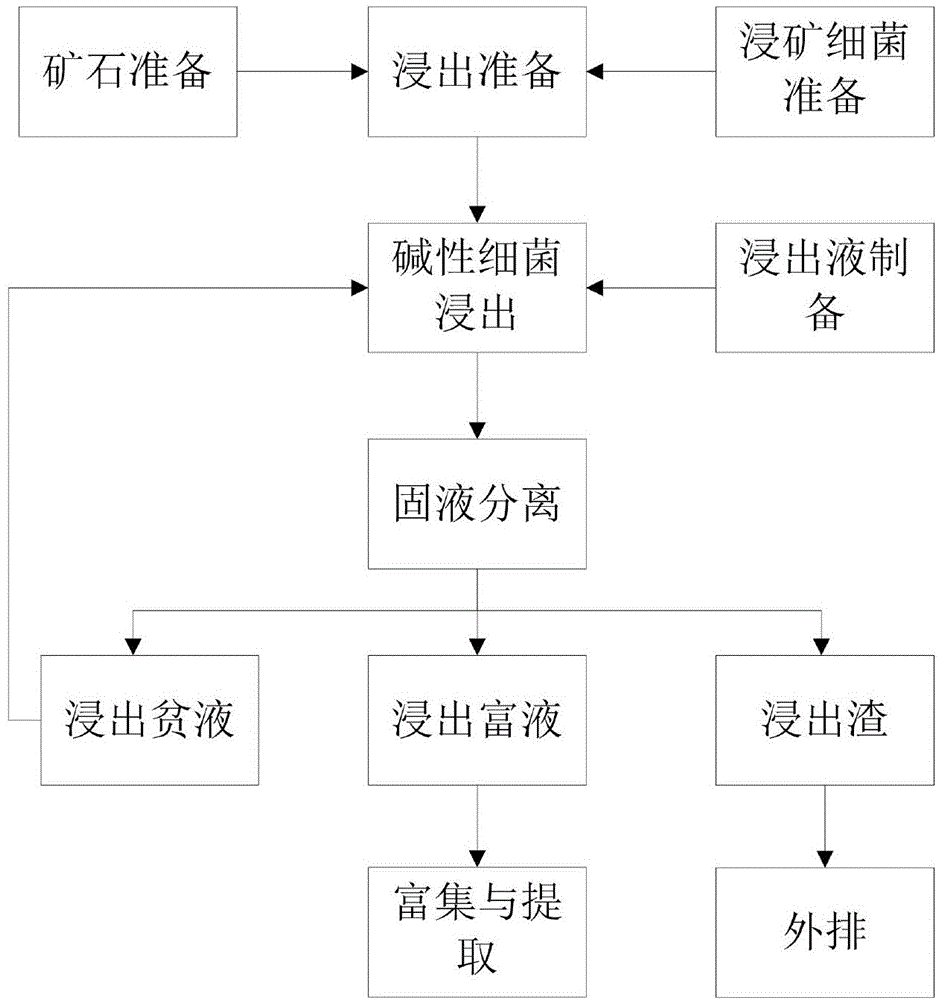

Image

Examples

Embodiment 1

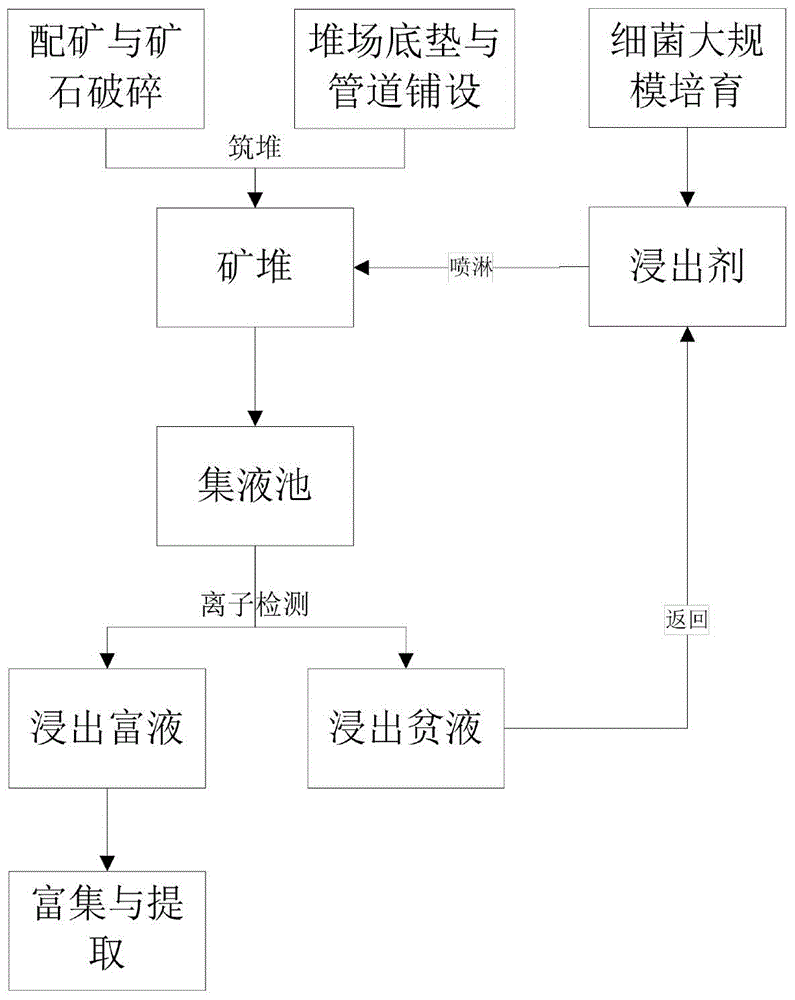

[0020] Taking heap leaching as an example to illustrate the specific implementation method of this new process, the process flow is as follows figure 2 shown.

[0021] Step 1: Preparation for leaching

[0022] A domestic copper mine is a copper oxide mine with high alkaline gangue content, the oxidation rate of the copper mine is 35%-65%, and the copper grade of the ore is 0.9-1.3%. The ore is crushed so that the maximum particle size of the ore does not exceed 50mm. Lay the anti-seepage pad in the storage yard, and lay the leachate circulation pipeline system at the same time. The area of the ore heap is 800m×150m, and the height of the ore heap is 2-5m.

[0023] The alkaline bacterium JAT-1 was cultivated on a large scale under the condition of pH=9 by using a bacterial fermenter, and the changes of the bacterial concentration and the pH of the bacterial solution were monitored during the cultivation process. When the bacterial concentration reached 1×10 7 ~1×10 8 p...

Embodiment 2

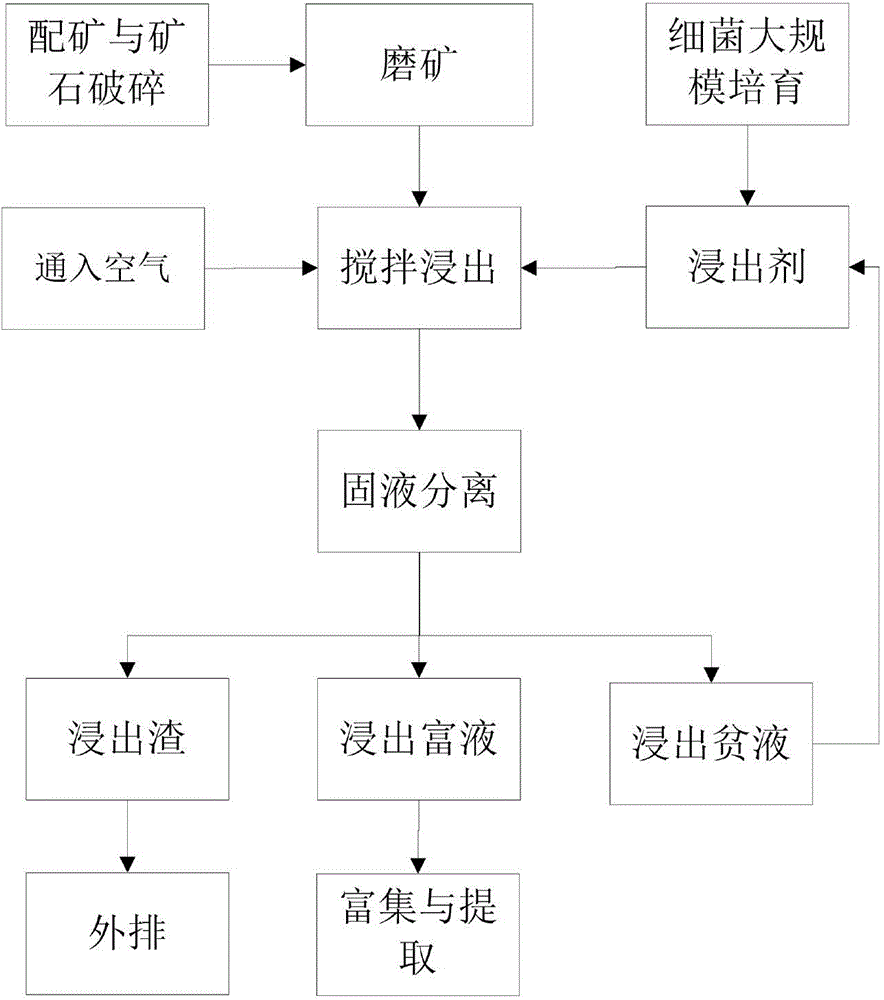

[0030] Taking stirring leaching as an example to illustrate the specific implementation method of this new process, the process flow is as follows image 3 shown.

[0031] Step 1: Preparation for leaching

[0032] The oxidation rate of high-alkaline gangue copper oxide ore is 35% to 65%, and the ore copper grade is 0.8% to 1.3%. The copper oxide ore is mainly malachite and chrysocolla, followed by azurite. The ore is crushed and ground to make the ore particle size +200 mesh content reach more than 80%, while -200 mesh content is less than 20%.

[0033] Use a bacterial fermenter to cultivate alkaline bacteria JAT-1 on a large scale under the condition of pH=9, monitor the changes in bacterial concentration and pH value of the bacterial solution during the bacterial growth process, and wait until the bacterial concentration reaches 1×10 8 ~1×10 9 pcs / ml, take bacterial liquid and mix with liquid culture medium to make leaching agent. The ratio of bacterial liquid to liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com