Method for manufacturing multilayer nanowires by template electrochemical synthesis technology

An electrochemical and nanowire technology, applied in the field of preparing multilayer nanowires by template electrochemical synthesis technology, can solve the problems of reducing GMR performance and affecting the magnetic properties of multilayer nanowires, and avoid thermal stress and interlayer thermal diffusion , controllable nanowire length, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

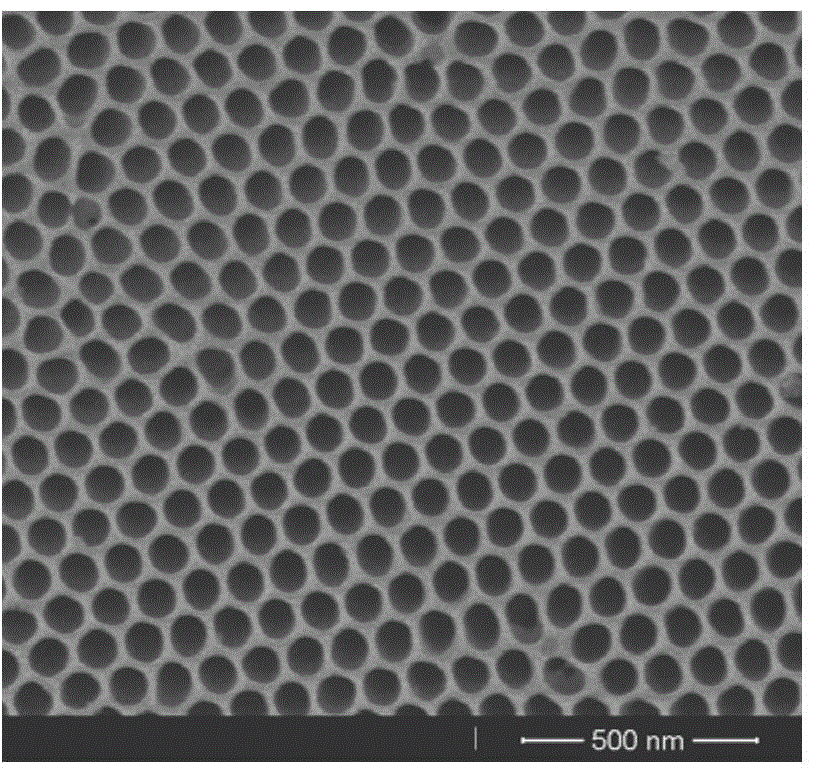

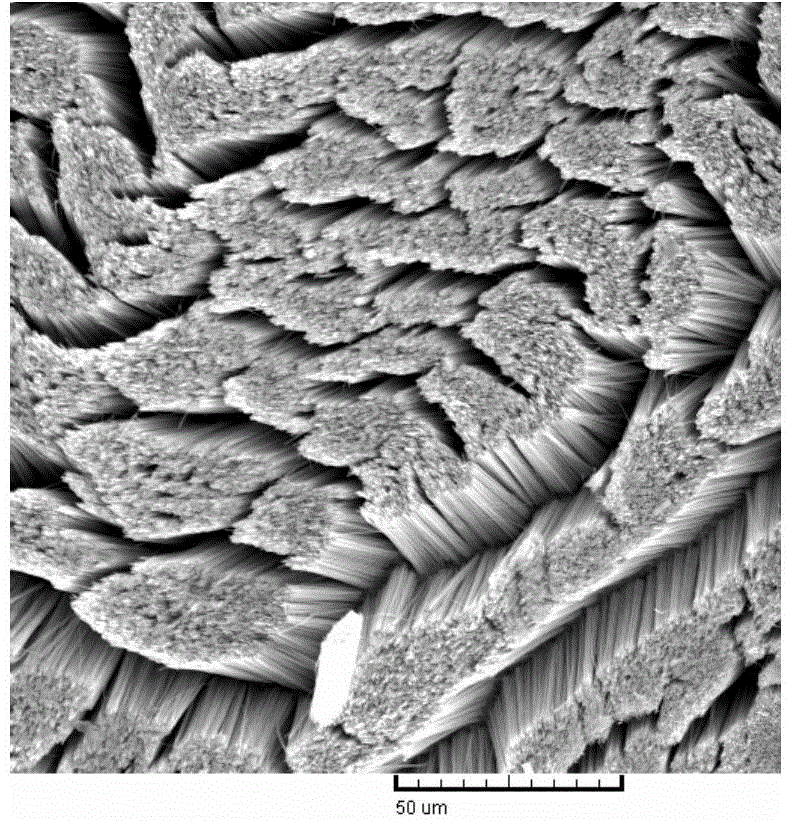

[0028] The secondary anodic aluminum oxide film (AAO) template for preparing NiFe / Cu / Co / Cu multilayer nanowires can also be prepared according to the following process in addition to the commercially available AAO template: mechanically polish high-purity aluminum sheets, remove After the oil was placed in 4wt% oxalic acid solution, it was anodized at a voltage of 50V; the oxide film was peeled off from the aluminum substrate and soaked in 3.5wt% H 3 PO 4 The barrier layer was removed in the solution to obtain a through-AAO film; a layer of Au film was sputtered on one side of the through-AAO film as a conductive layer, which was fixed on a Cu chip to make an AAO template. The AAO template electrodes in Examples 2-5 were all prepared by this process. The surface morphology of the AAO template is attached figure 1 .

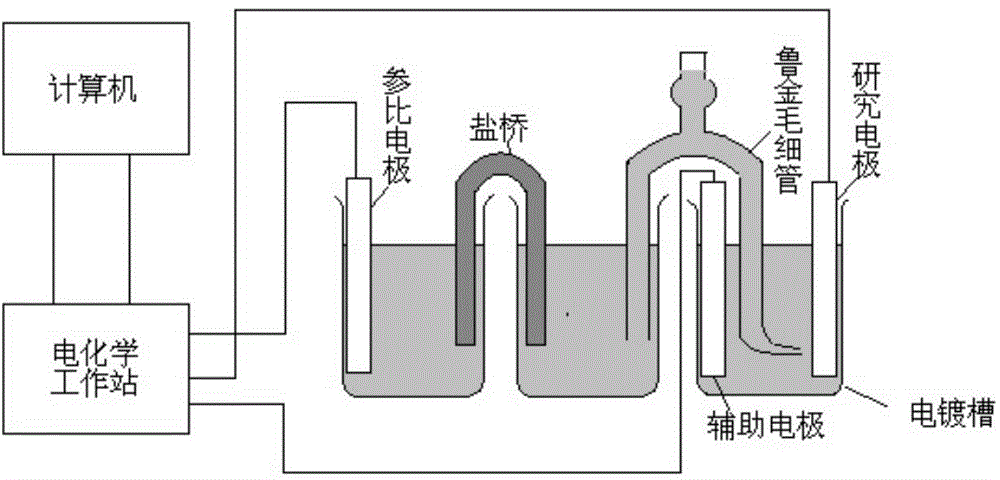

[0029]Using the secondary anodic aluminum oxide film (AAO) as a template, the electrochemical workstation and supporting software are combined with a three-ele...

example 2

[0035] Using the secondary anodic aluminum oxide film (AAO) as a template, the electrochemical workstation and supporting software are combined with a three-electrode system (the auxiliary electrode is a platinum mesh, the reference electrode is a saturated calomel electrode SCE, and the working electrode is a secondary electrode sprayed with gold at the bottom). Anodized aluminum film) NiFe / Cu / Co / Cu multilayer nanowires were deposited using three electroplating tanks with controlled potential. First place the secondary anodized aluminum film electrode in the NiFe electroplating tank, deposit NiFe alloy with controlled potential, and then quickly switch to the Cu electroplating tank after ultrasonic cleaning, deposit Cu with controlled potential, and then quickly switch to the Co plating tank after ultrasonic cleaning In the process, Co is deposited by controlled potential, then ultrasonically cleaned, quickly switched to the Cu electroplating tank, and Cu is deposited by contr...

example 3

[0041] Using the secondary anodic aluminum oxide film (AAO) as a template, the electrochemical workstation and supporting software are combined with a three-electrode system (the auxiliary electrode is a platinum mesh, the reference electrode is a saturated calomel electrode SCE, and the working electrode is a secondary electrode sprayed with gold at the bottom). Anodized aluminum film) NiFe / Cu / Co / Cu multilayer nanowires were deposited using three electroplating tanks with controlled potential. First place the secondary anodized aluminum film electrode in the NiFe electroplating tank, deposit NiFe alloy with controlled potential, and then quickly switch to the Cu electroplating tank after ultrasonic cleaning, deposit Cu with controlled potential, and then quickly switch to the Co plating tank after ultrasonic cleaning In the process, Co is deposited by controlled potential, then ultrasonically cleaned, quickly switched to the Cu electroplating tank, and Cu is deposited by contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com