Cleaning liquid for regenerating denitration catalyst and cleaning method

A denitrification catalyst and cleaning solution technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of reducing usage, prolonging catalyst life, and reducing regeneration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

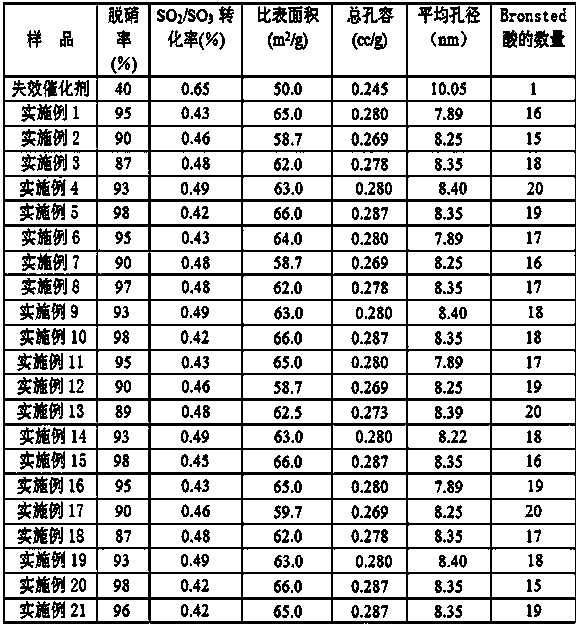

Examples

Embodiment 1

[0017] In the cleaning device, prepare the cleaning solution: use deionized water as solvent, add 0.5wt% surfactant polyoxyethylene ether and 5wt% selective heavy metal scavenger HMCA-1; buffer solution is ammonium hydrogen phthalate-dilute Sulfuric acid, the preparation method is to mix 25.0mL of ammonium hydrogen phthalate solution with a concentration of 0.2 mol / L and 800mL of dilute sulfuric acid with a concentration of 0.1 mol / L, and dilute with water until the pH value is 4.5; The operation procedure of washing with cleaning ingredients and finally rinsing with acid buffer solution is to wash 3 times with high-pressure deionized water, then wash in ultrasonic equipment with cleaning solution for 0.1h, and finally wash in ultrasonic equipment with acid buffer solution for 6h. The selective heavy metal scavenger HMCA-1 is selected from the heavy metal scavenger produced by Suzhou Sujing Environmental Protection Technology Co., Ltd.

Embodiment 2

[0019] In the cleaning device, prepare the cleaning solution: take deionized water as solvent, add 0.01wt% surfactant polyoxyethylene ether and 1wt% selective heavy metal scavenger HMCA-1; the buffer solution is oxalic acid-ammonium oxalate, and the preparation method is Mix 25.0mL of oxalic acid solution with a concentration of 0.2 mol / L and 17.5mL of ammonium oxalate with a concentration of 0.1 mol / L, and dilute with water until the pH value is 5.5. The operation procedure of washing is to wash 4 times with high-pressure deionized water, then wash in ultrasonic equipment with cleaning solution for 6 hours, and finally wash in ultrasonic equipment with acid buffer solution for 0.1 hour. The selective heavy metal scavenger HMCA-1 is selected from the heavy metal scavenger produced by Suzhou Sujing Environmental Protection Technology Co., Ltd.

Embodiment 3

[0021] In the cleaning device, prepare the cleaning solution: take deionized water as solvent, add 1wt% surfactant polyoxyethylene ether and 10wt% selective heavy metal scavenger HMCA-1; buffer solution is hexamethylenetetramine-sulfuric acid, The preparation method is: dissolve 40g of hexamethylenetetramine in 200mL of water, add 10mL of dilute sulfuric acid with a concentration of 0.1 mol / L, and then dilute with water until the pH value is 5; the cleaning method is as follows: washing with water first, then washing with cleaning solution, and finally acid buffering The operation procedure of solution washing is to wash 5 times with high-pressure deionized water, then wash in ultrasonic equipment with cleaning solution for 1 hour, and finally wash in ultrasonic equipment with acidic buffer solution for 5 hours. The selective heavy metal scavenger HMCA-1 is selected from the heavy metal scavenger produced by Suzhou Sujing Environmental Protection Technology Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com