Special ultrafine tiopronin powder lyophilized preparation and preparation method thereof

An ultra-fine powder, tiopronin technology, applied in the field of medicine, can solve the problems of low clarity of tiopronin, small specific surface area, large toxic and side effects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

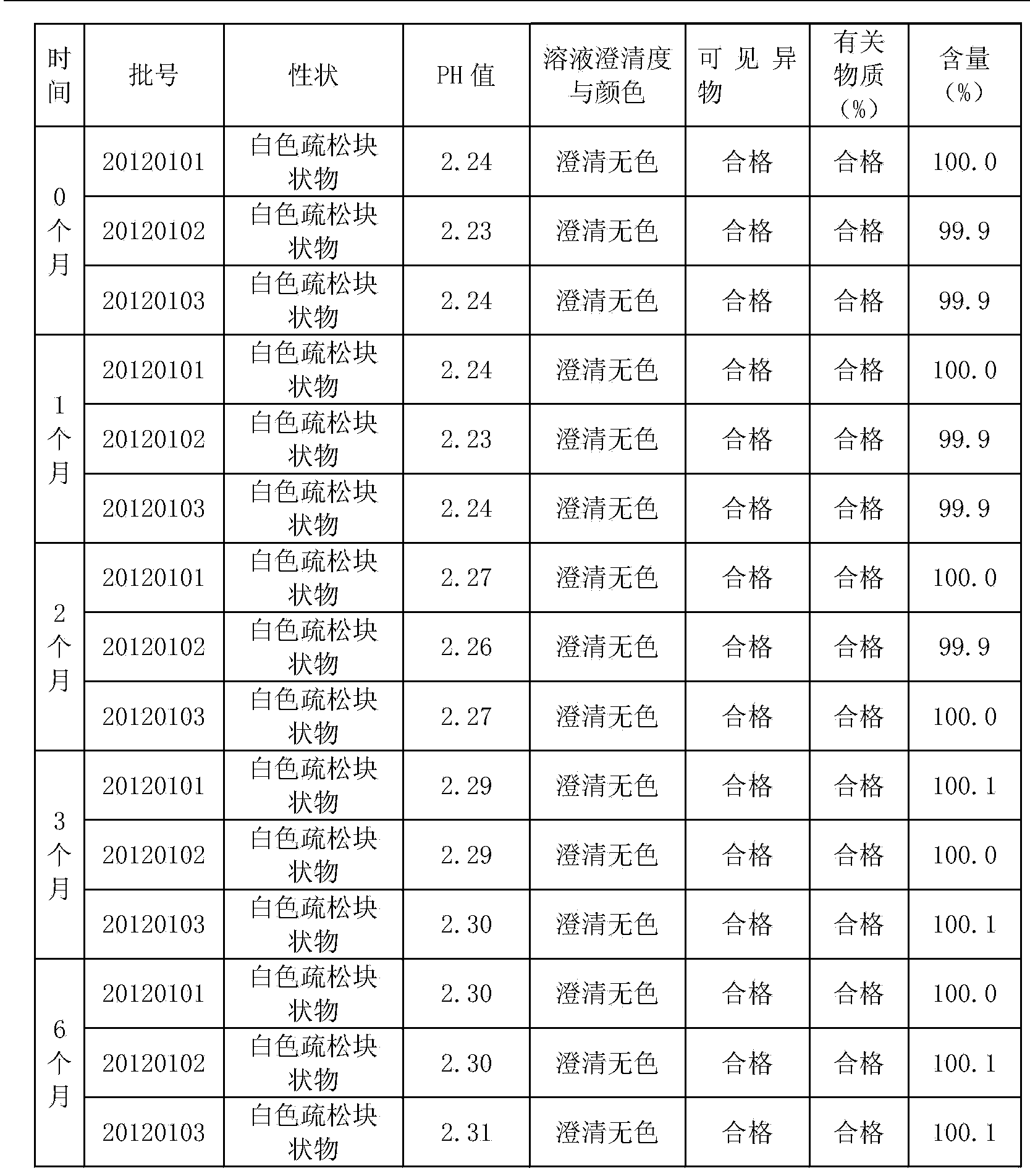

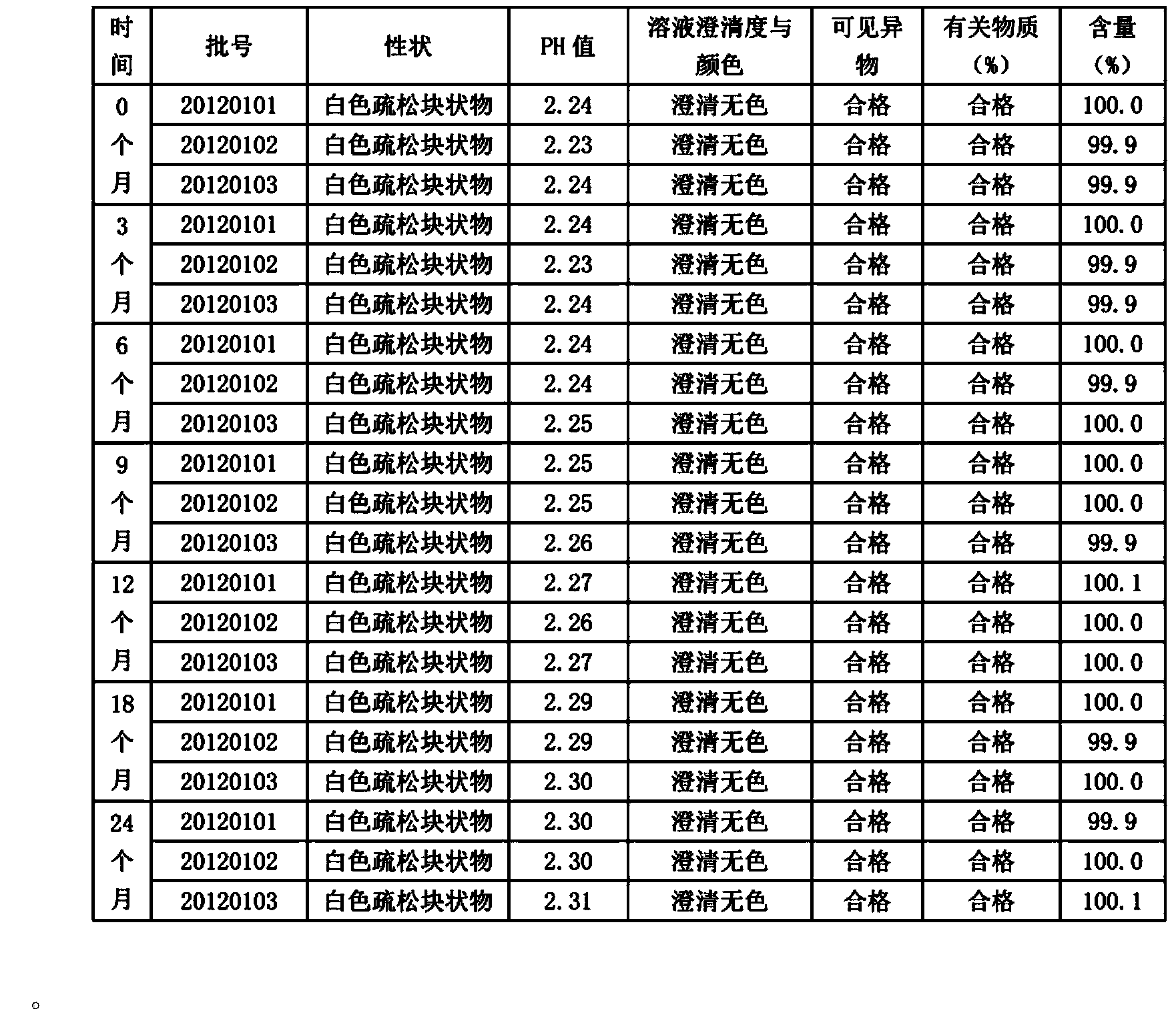

Examples

Embodiment 1

[0022] Add 163 grams (1.5 mol) of 2-chloropropionic acid and 68.7 grams (0.5 mol) of phosphorus trichloride to a dry 500ml reaction bottle, stir and react under the condition of blocking moisture, and react for 4 hours at a reaction temperature of 40°C to generate 2 - Chloropropionyl chloride. After the reaction was finished, the distillate at 107-113° C. was collected by distillation to obtain 181 grams of 2-chloropropionyl chloride as a colorless liquid, with a yield of 95%. Add 37.5 g (0.5 mol) of glycine, 26.5 g (0.25 mol) of anhydrous sodium carbonate and 250 ml of water to a 1000 ml reaction bottle, stir to dissolve. Cool in an ice-salt bath, add 63.5 g (0.5 mol) of 2-chloropropionyl chloride dropwise under vigorous stirring, and control the reaction temperature at -5°C. At the same time, add a saturated solution of anhydrous sodium carbonate to make the reaction solution weakly alkaline. After the addition was complete, the stirring reaction was continued for 3 hours. ...

Embodiment 2

[0030]Add 163 grams (1.5 mol) of 2-chloropropionic acid and 68.7 grams (0.5 mol) of phosphorus trichloride to a dry 500ml reaction bottle, stir and react under the condition of blocking moisture, and react at a reaction temperature of 45°C for 3.5 hours to generate 2 - Chloropropionyl chloride. After the reaction, the distillate at 107-113° C. was collected by distillation to obtain 183 grams of 2-chloropropionyl chloride as a colorless liquid, with a yield of 96.1%. Add 37.5 g (0.5 mol) of glycine, 26.5 g (0.25 mol) of anhydrous sodium carbonate and 250 ml of water to a 1000 ml reaction bottle, stir to dissolve. Cool in an ice-salt bath, add 63.5 g (0.5 mol) of 2-chloropropionyl chloride dropwise under vigorous stirring, and control the reaction temperature at -10°C. At the same time, add a saturated solution of anhydrous sodium carbonate to make the reaction solution weakly alkaline. After the addition was complete, the stirring reaction was continued for 4 hours. After th...

Embodiment 3

[0038] Add 163 grams (1.5 mol) of 2-chloropropionic acid and 68.7 grams (0.5 mol) of phosphorus trichloride to a dry 500ml reaction bottle, stir and react under the condition of blocking moisture, and react at a reaction temperature of 50°C for 3 hours to generate 2 - Chloropropionyl chloride. After the reaction, the distillate at 107-113° C. was collected by distillation to obtain 182 grams of 2-chloropropionyl chloride as a colorless liquid, with a yield of 95.6%. Add 37.5 g (0.5 mol) of glycine, 26.5 g (0.25 mol) of anhydrous sodium carbonate and 250 ml of water to a 1000 ml reaction bottle, stir to dissolve. Cool in an ice-salt bath, add 63.5 g (0.5 mol) of 2-chloropropionyl chloride dropwise under vigorous stirring, and control the reaction temperature at -15°C. At the same time, add a saturated solution of anhydrous sodium carbonate to make the reaction solution weakly alkaline. After the addition was complete, the stirring reaction was continued for 5 hours. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com