Antirust high-temperature lubricating grease composition

A lubricating grease and high temperature technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as not being able to meet the performance requirements of anti-seize, and achieve the effect of excellent high-temperature anti-seize performance and excellent protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

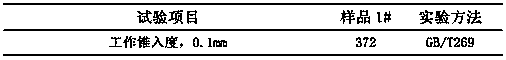

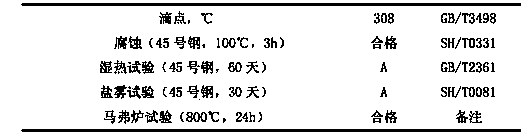

[0047] The mineral base oil that mass ratio is 20% joins in the kettle, is warming up to 85 ℃, adds the lauryl hydroxystearic acid that the mass ratio is 5% and the azelaic acid that the mass ratio is 1%, then adds by 5 times water Dissolve lithium hydroxide with a mass ratio of 1%, and raise the temperature to 105-115° C. for 3 hours. Then the temperature is raised for dehydration, and when the temperature is raised to 160° C., 1% diisooctyldiphenylamine is added in a mass ratio, and the maximum temperature is 208° C. Adding mass ratio is 15% mineral oil to lower the temperature, when the temperature drops below 150°C, add the remaining mass ratio of 5% mineral oil, 23% double ester and 30% poly-alpha olefin synthesis Oil, add 2% barium petroleum sulfonate, 8% graphite, 10% copper powder, 8% aluminum powder, 5% boron nitride, 2% polymethacrylate when the temperature is lower than 90°C . Finally, grind and homogenize on three-axis rollers, and measure the grease performance....

example 2

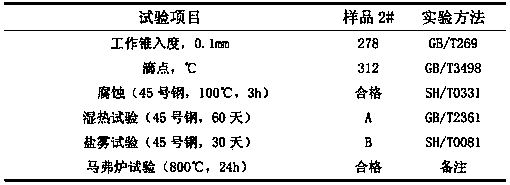

[0054] The mineral base oil that is 40% in mass ratio is added in the still, is heated up to 85 ℃, adds the dodecyl hydroxystearic acid and the sebacic acid of 9.3% in mass ratio, then adds the 2.6 that dissolves by 5 times of water % lithium hydroxide, the temperature was raised to 105-115°C for 2 hours. Then heat up for dehydration, add 2% diphenylamine when the temperature rises to 150°C, and the maximum temperature is 220°C. Add 20% poly-alpha olefin synthetic oil to cool down, add the remaining 25% dipentaerythritol ester when the temperature drops below 150°C, add 5% barium petroleum sulfonate, 1% 2,5 -Dimercapto-1,3,4-thiadiazole dimer, 10% graphite, 5% copper powder, 5% aluminum powder, 10% boron nitride, 1% ethylene-propylene copolymer, 5% tetrachloroethylene. Finally, grind and homogenize on three-axis rollers, and measure the grease performance.

[0055] The performance of the lubricating grease that process formula of the present invention makes is listed in tabl...

example 3

[0060] Add mineral base oil with a mass ratio of 20% into the kettle, heat up to 85°C, add 3% lauryl hydroxystearic acid and 1% sebacic acid with a mass ratio, and then add 0.8 % lithium hydroxide, the temperature was raised to 105-115°C for 2.5 hours. Then heat up for dehydration, add 2% phenyl-α-naphthylamine when the temperature rises to 150°C, and the maximum temperature is 200°C. Add 20.2% mineral oil to lower the temperature. When the temperature drops below 150°C, add the remaining 25% pentaerythritol ester and 30% poly-alpha olefin synthetic oil. When the temperature is lower than 90°C, add 5% barium petroleum sulfonate, 1 % Benzotriazole, 5% graphite, 5% copper powder, 5% aluminum powder, 8% boron nitride, 5% polymethacrylate, 3% trichloroethylene. Finally, grind and homogenize on three-axis rollers, and measure the grease performance.

[0061] The performance of the lubricating grease that process formula of the present invention makes is listed in table 3

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com