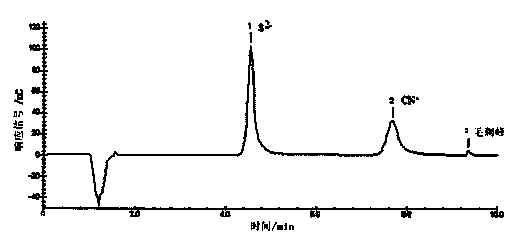

Method for detecting total cyanide and sulfide through online photolysis-noncontact diffusion-chromatographic separation

A chromatographic separation and sulfide technology, applied in the field of total cyanide and sulfide, can solve the problems of changing ion chromatograph, difficult operation, complicated conversion system, etc., achieving good selectivity, less consumption of reagents and samples, and laboratory costs. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take no less than 20mL of wastewater from the treatment tank, filter with fast filter paper, the quantitative loop is 100μL, the sample solution flow rate is 1.5mL / min; light source 8w (on), 312nm, narrow wave; spiral ring photolysis tube, hard glass, inner diameter 0.5mm, length 1.1m; light time, 7min (programmable stop flow 1~999s); gas-liquid membrane separation and diffusion unit, hydrophobic membrane φ47mm, pore size 0.55μm; water flow rate in the first peristaltic pump 0.5mL / min, acid The solution flow rate is 0.8mL / min, the composition is a mixture of 0.5mol / L phosphoric acid and 0.1mol / L hypophosphorous acid, containing 0.001mol / L~0.1mol / L sulfamic acid, ascorbic acid, EDTA, citric acid (sulfamic acid The contents of acid, ascorbic acid, EDTA, and citric acid are all greater than 0); the flow rate of the alkaline absorption solution is 0.8 mL / min, and the composition is 0.001 mol / L ethylene diamine and 0.01 mol / L sodium hydroxide. Capture column, IonPac AG7; sepa...

Embodiment 2

[0050] The equipment and operating procedures are the same as in Example 1. Take a certain amount of water sample from the conditioning pool, filter it with fast filter paper, the quantitative loop is 200μL, the sample solution flow rate is 1.3mL / min; the light source is 8w (off), 312nm, narrow wave; spiral ring photolysis Tube, hard glass, inner diameter 0.5mm, length 1.1m; light time, 6min (programmable stop flow 1~999s); gas-liquid membrane separation and diffusion unit, hydrophobic membrane φ47mm, pore size 0.65μm; water in the first peristaltic pump The flow rate is 0.6mL / min, and the acidic solution flow rate is 0.8mL / min. The composition is a mixture of 0.5mol / L phosphoric acid and 0.1mol / L hypophosphorous acid, containing 0.001mo1 / L~0.1mol / L sulfamic acid, ascorbic acid, EDTA, citric acid; the flow rate of the alkaline absorption solution is 0.8mL / min, and the composition is 0.001mol / L ethylenediamine and 0.01mol / L sodium hydroxide. Capture column, Metrosep A PCC 1 HC / 4...

Embodiment 3

[0052] The equipment and operating procedures are as in Example 1. Take a sample of synthetic ammonia water and filter it with fast filter paper. The quantitative loop is 200μL, the sample solution flow rate is 1.3mL / min; the light source is 8w, 312nm, narrow wave; spiral ring photolysis tube, hard glass , Inner diameter 0.5mm, length 1.1m; light time, 8min; gas-liquid membrane separation and diffusion unit, hydrophobic membrane φ47mm, pore size 0.22μm; water flow rate in the first peristaltic pump 0.55mL / min, acid solution flow rate 0.85mL / min, composition It is a mixture of 0.5mol / L phosphoric acid and 0.1mol / L hypophosphorous acid, containing 0.001mol / L~0.1mol / L sulfamic acid, ascorbic acid, EDTA, and citric acid; the flow rate of the alkaline absorption solution is 0.75mL / min , The composition is 0.001mol / L ethylenediamine and 0.01mol / L sodium hydroxide. Capture column, Metrosep A PCC 1 VHC / 4.0; Separation column, AS7; Silver working electrode (Ag), three waveform integral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com