Device and method for detecting total cyanide and sulfide in water solution by employing direct conversion

An aqueous solution and sulfide technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult operation and complicated transformation system, achieve good selectivity, solve the mutual interference of determination, and eliminate the interference of coexisting reducing substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

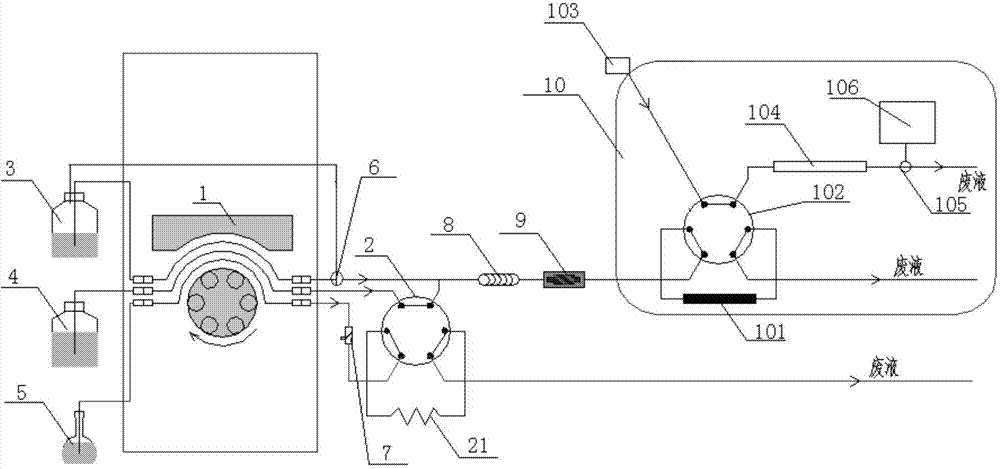

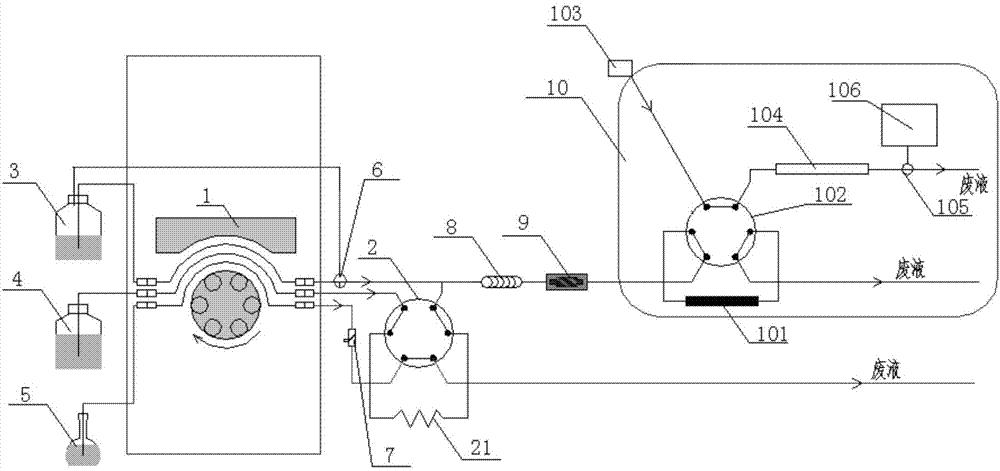

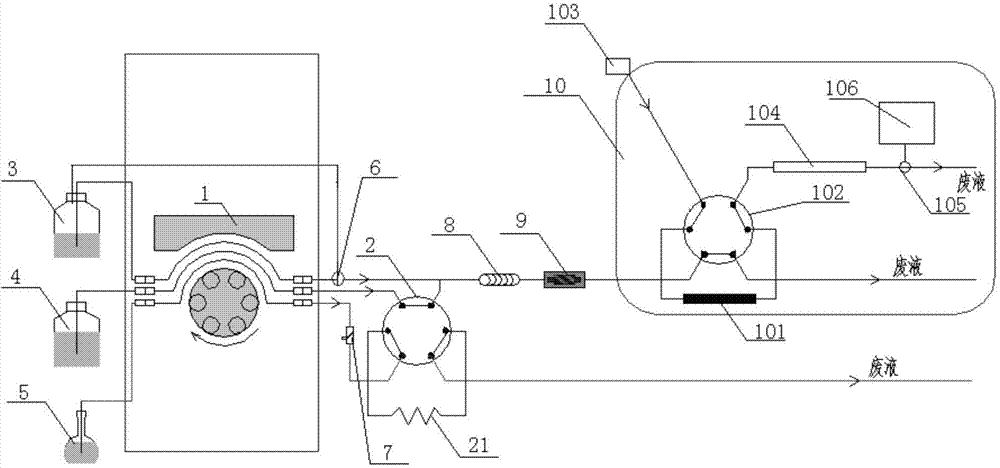

[0025] like figure 1As shown, this embodiment includes a peristaltic pump 1, a first six-way valve 2, a flow-carrying container 3 containing a stabilizer and an exchange agent, an alkaline solution or water container 4, a sample container 5, a three-way valve 6, and an online filter 7 , a mixing tube 8, a photolyzer 9 and an ion chromatograph 10; the inlet of the peristaltic pump 1 is respectively connected to a flow-carrying container 3 containing a stabilizer and an exchanger, an alkaline solution or a water container 4, a sample container 5, and a peristaltic pump 1 The outlets are respectively connected to the first six-way valve 2, three-way valve 6 and online filter 7, the first six-way valve 2 is connected to the mixing pipe 8, and the three-way valve 6 is respectively connected to the flow-carrying container 3 containing stabilizer and exchanger With the first six-way valve 2, the mixing tube 8 is connected to the photolyzer 9, and the photolyzer 9 is connected to the ...

Embodiment 2

[0033] In this embodiment, water samples from the scrubber are taken, and after filtration and adsorption, the sample solution is injected into the quantitative loop 21 manually or by the peristaltic pump 1 . In the device, the volume of the quantitative loop 21 is 100 μL; the flow rate of the stabilizer and the exchanger is 0.4mL / min, and the stabilizer and the exchanger are iron-titanium reagent, sodium citrate and sulfamic acid, and the content is 0.02mol / L; Pure water carrier liquid, flow rate of pure water solvent 0.3mL / min; light source 8w, 312nm, narrow wave; spiral ring photolysis tube, hard glass, inner diameter 0.5mm, length 10m; illumination time, 9min; capture column 101, AG7; separation column 104, AS7; amperometric cell potential, 20mV; eluent, 0.5mol / L sodium acetate + 0.1mol / L sodium hydroxide + 0.5% m / m ethylenediamine; eluent flow rate, 1.0mL / After 9 minutes, change the eluent to 0.1mol / L sodium hydroxide + 5% v / v acetone. DX-500 ion chromatograph 10 system...

Embodiment 3

[0035] In this embodiment, a synthetic ammonia water sample is taken, and after filtration and adsorption, the sample solution is injected into the quantitative loop 21 manually or by a peristaltic pump 1 . In the device, the volume of the quantitative loop 21 is 200 μL; the flow rate of the stabilizer and the exchanger is 0.4mL / min, and the stabilizer and the exchanger are ethylenediaminetetraacetate and hypophosphite with a content of 0.02mol / L; Enter the pure water carrier liquid, the flow rate of pure water solvent is 0.4mL / min; light source 8w, 312nm, narrow wave; spiral ring photolysis tube, hard glass, inner diameter 0.5mm, length 10m; illumination time, 8min; capture column 101 , Metrosep A PCC 1HC / 4.0; separation column 104, Metrosep A Supp 4 separation column 104; amperometric cell potential, 10mV; eluent, 0.1mol / L sodium hydroxide+3.5% acetone v / v; eluent flow rate, 0.01min, 0.8mL / min; 9min later, 1.8mL / min. The sulfide peak and cyanide peak were separated by the 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com