Steam inside-heat-transfer type composite reaction kettle for AC foaming agent

A reaction kettle and foaming agent technology, which is applied in the field of AC foaming agent steam internal heat transfer composite reactor, can solve the problems of not reaching the theoretical temperature and uniform effect, affecting the normal operation of the agitator, and limited heating area. , to achieve the effect of saving steam and water resources, reducing side reactions, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

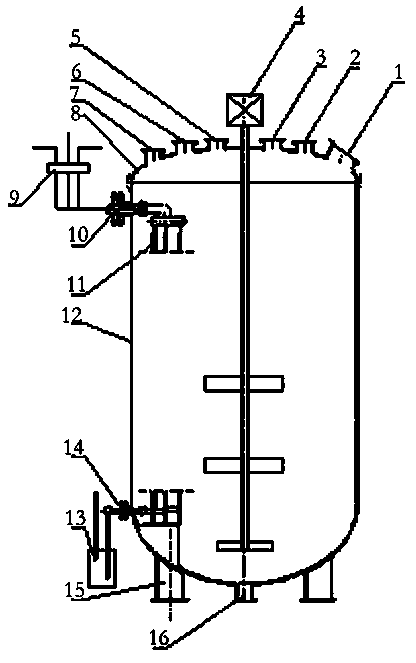

[0033] The condensation reaction of biuret is carried out under the acidic condition of the AC blowing agent steam internal heat transfer type composite reactor equipped with the DCS automatic control system as described above.

[0034] Make a steam-heated reactor with an inner diameter of 600mm, such as figure 1As shown, inside the reactor, the ratio of the diameter of the stirring blades of the stirring device to the inner diameter of the reactor at the relative position is 1 / 3, and 18 sets of tubular heating assemblies are vertically arranged, and the diameter of the heating assemblies is 60 mm. The steam heating distribution part of the port is connected with the steam and heating components respectively.

[0035] At the beginning of the reaction, add appropriate amount of hydrazine hydrate, ammonia water and sulfuric acid into the reactor through DCS system adjustment, turn on the stirring motor of the reactor, the temperature in the reactor rises slightly, turn on the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com