Method for grinding viscous medicine with zirconium beads

A grinding method and viscous technology, which is applied in the field of pharmaceutical grinding and dispersion, can solve the problems of affecting the grinding quality and drug stability, accelerating the wear and breaking of beads, and unsatisfactory grinding fineness, so as to be beneficial to human body absorption and reduce production costs. Low, the effect of ensuring drug safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment relates to the preparation of zirconium beads (yttria-stabilized zirconia microspheres with a diameter of 1.0 to 2.0 mm) used in the viscous drug zirconium bead grinding method; the method specifically includes the following steps:

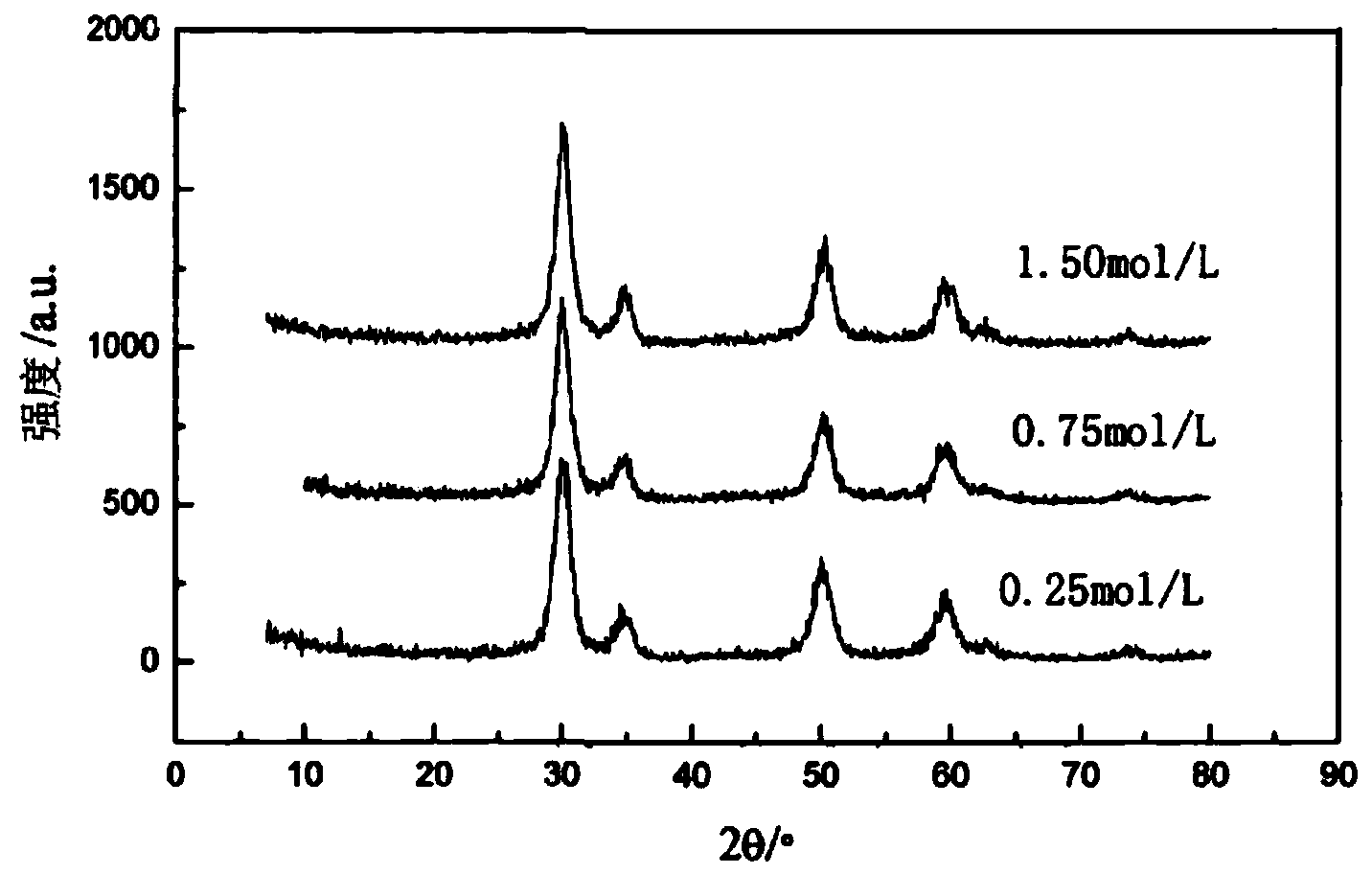

[0033] a. Press Y 2 o 3 Content is the ratio of 3mol%, configuration ZrO(NO 3 ) 2 .2H 2 O and Y (NO 3 ) 3 .6H 2 O mixed solution is the mother liquor; take ZrO(NO 3 ) 2 The concentrations are 0.25mol / L, 0.75mol / L, 1.5mol / L respectively;

[0034] b. At 80°C, add chitosan and pectin, adjust the pH value to 1, age and polymerize to form a gel, and dry to obtain a precursor;

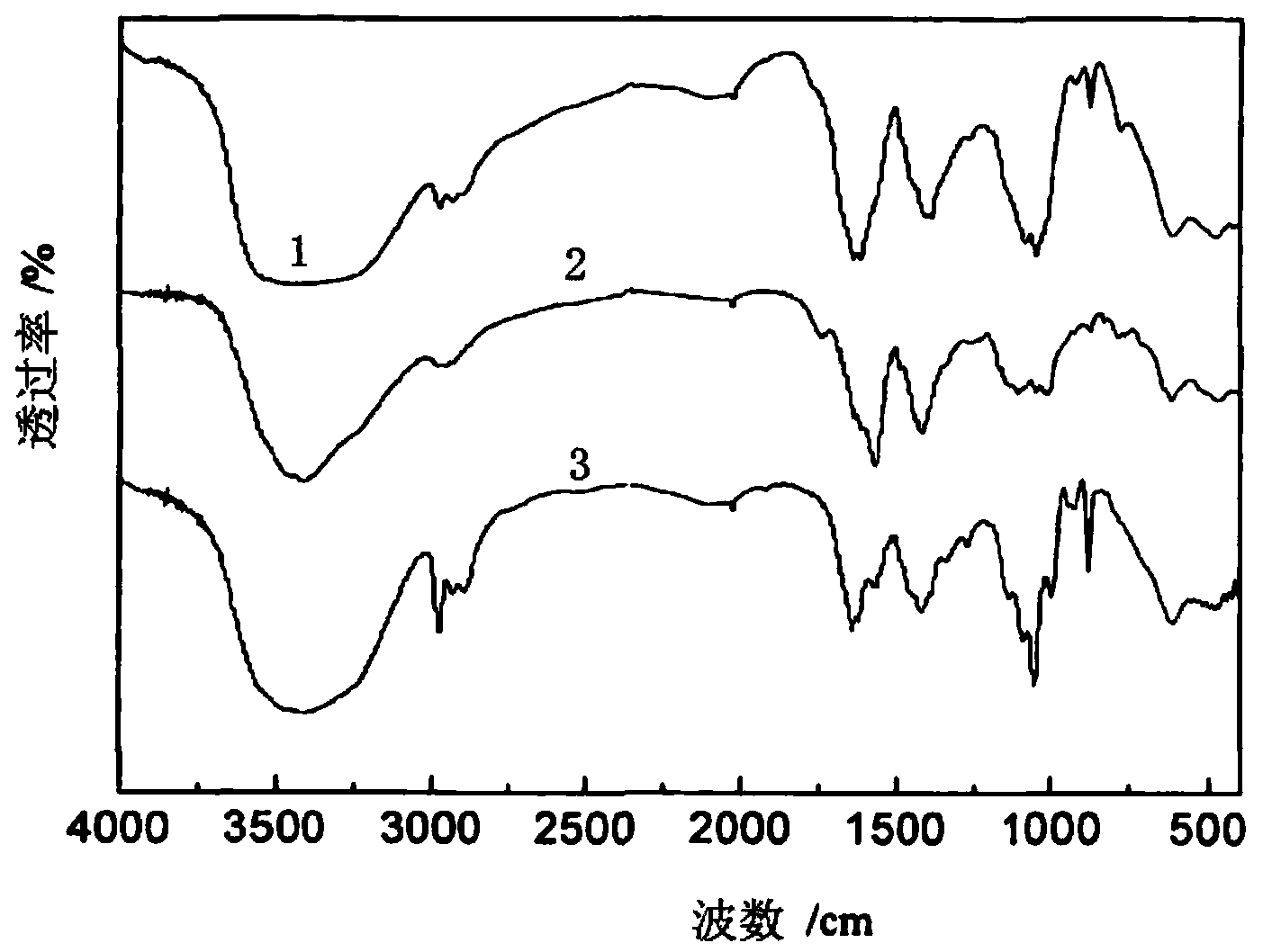

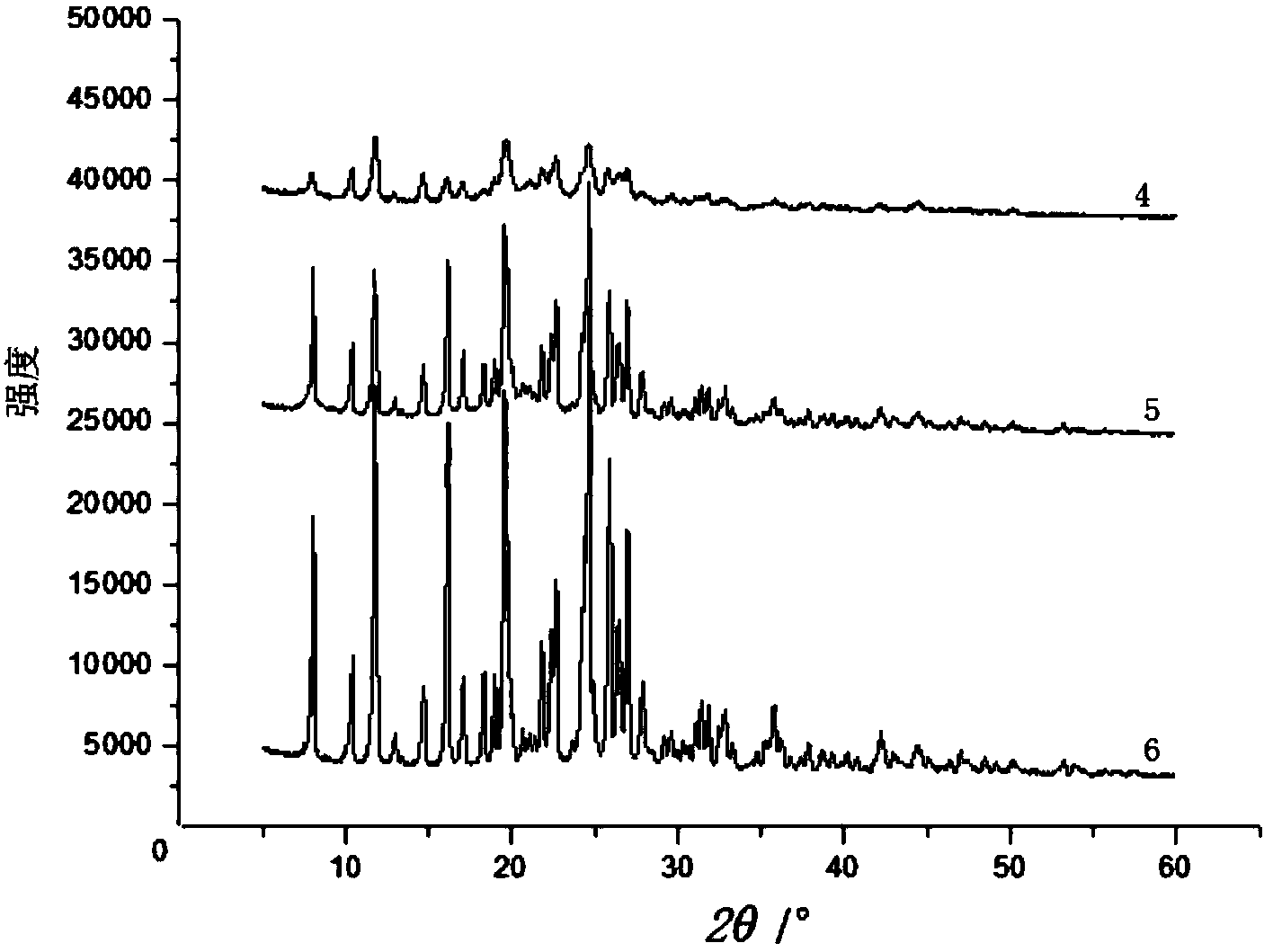

[0035] ZrO(NO 3 ) 2 The infrared spectrum of the corresponding precursor when the concentration is 0.75mol / L is as follows figure 1 As shown, the stretching vibration peak of O-H in the gel is around the wave number 3410 / cm, and the stretching vibration peak of -COOH at 1630 / cm is enhanced compared with chitosan and pectin, and at 1422cm -1 Co...

Embodiment 2

[0049] This embodiment relates to a method for grinding viscous drug zirconium beads, specifically using the yttria-stabilized zirconia microbeads with a diameter of 2mm prepared in Example 1 for grinding, specifically: putting the zirconium beads into a rotating disk In the stainless steel container, after adding the viscous drug, start the rotating disc to drive the zirconium beads to roll up and down for grinding, the grinding speed is 800-2800 rpm; the grinding time is adjusted according to the viscosity of the viscous drug.

[0050] Taking nifedipine as an example, the grinding experiment was carried out. Nifedipine belongs to poorly soluble drugs, limited by its solubility characteristics, it has the problems of low dissolution rate and low bioavailability. In order to improve the bioavailability, the particle size is reduced by grinding, the effective dissolution area of the drug is increased, and the dissolution rate of the drug is increased. Grinding efficiency and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com