Gold nanoparticle thin film wrapped by organic ligand and field electron emission device of gold nanoparticle thin film

A gold nanoparticle, organic ligand technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of poor emission electron monochromaticity, difficult to self-assemble monolayer film in large area, complicated preparation conditions, etc. Large emission area, convenient preparation method, and good monochromatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

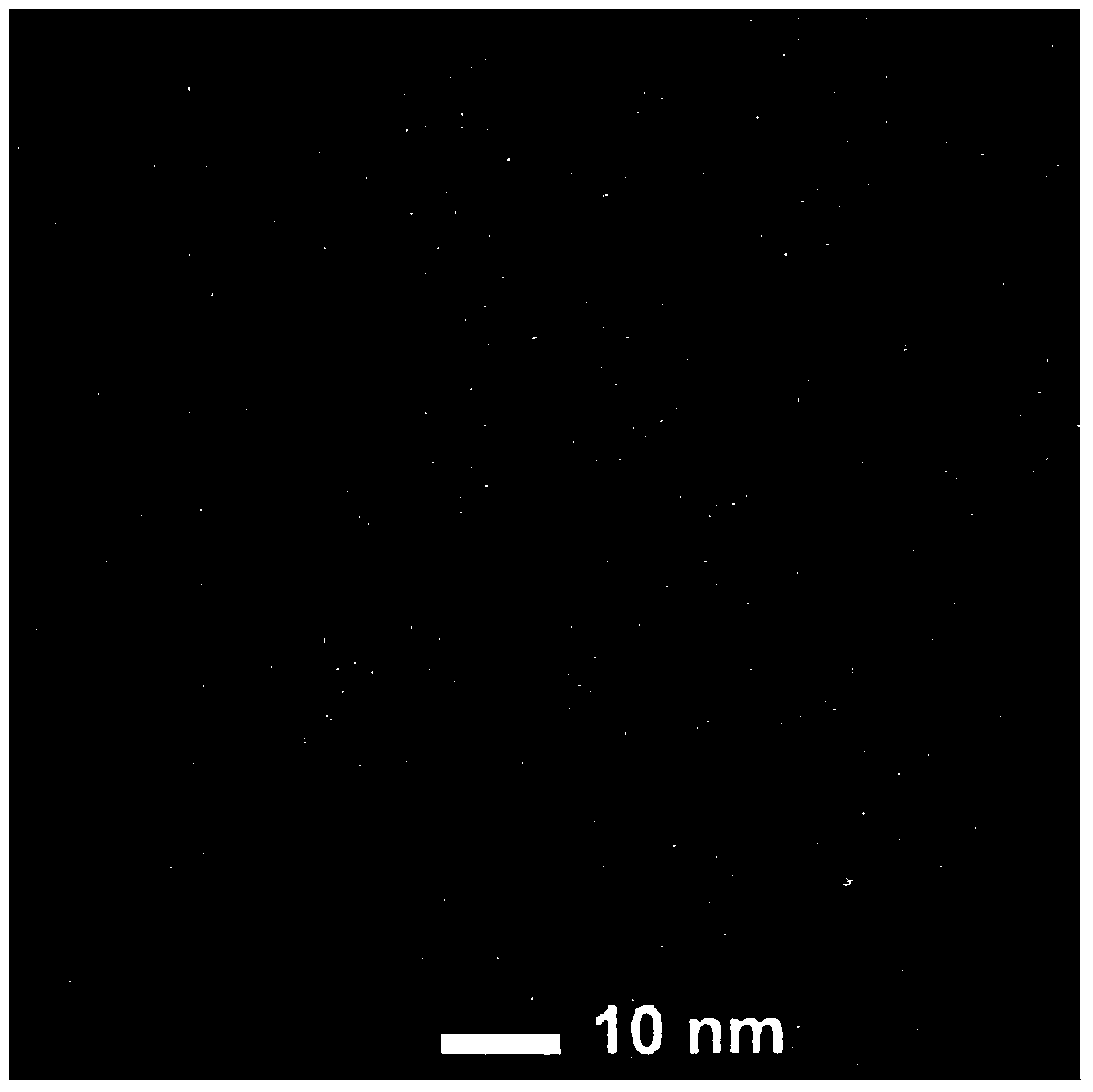

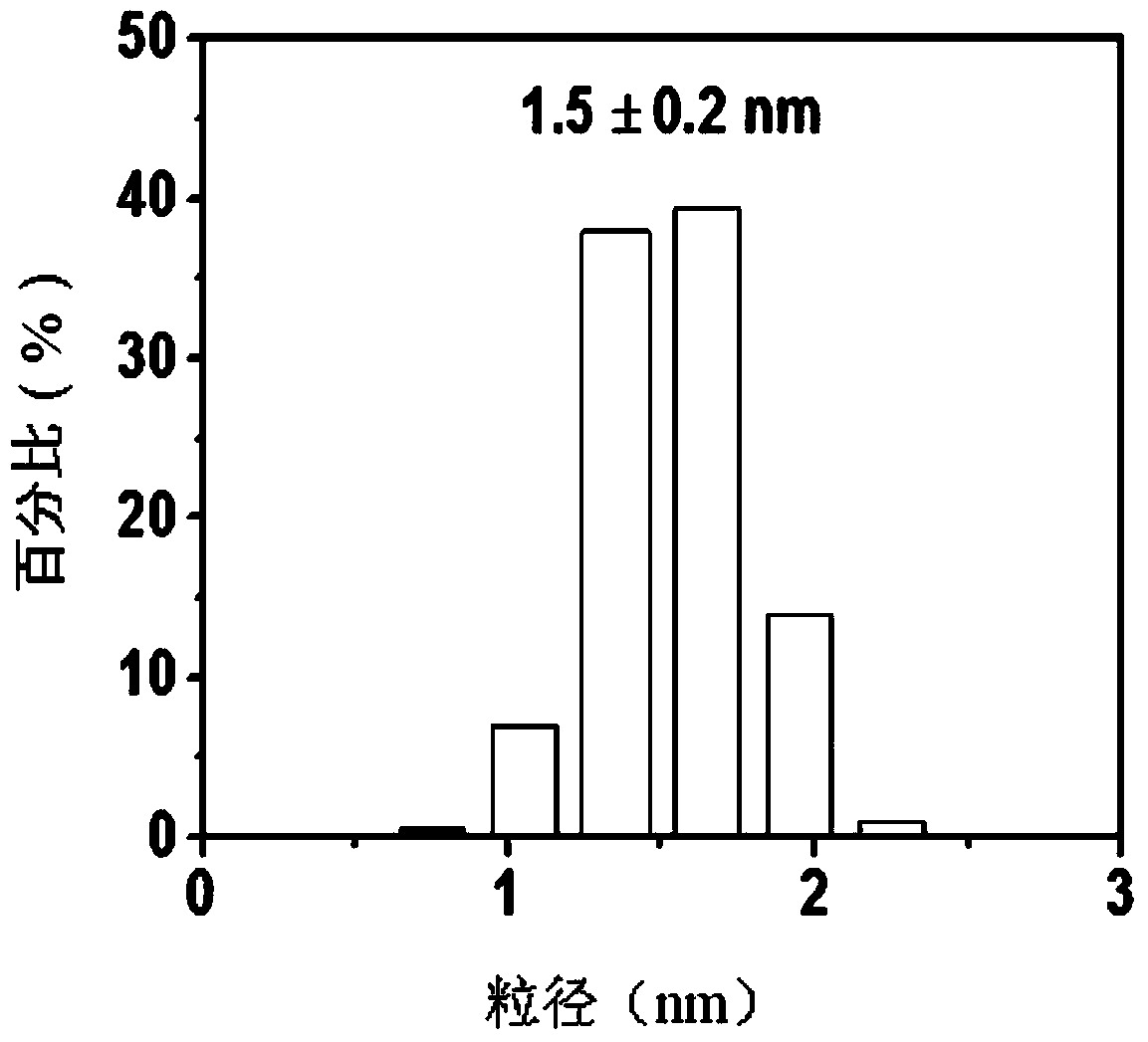

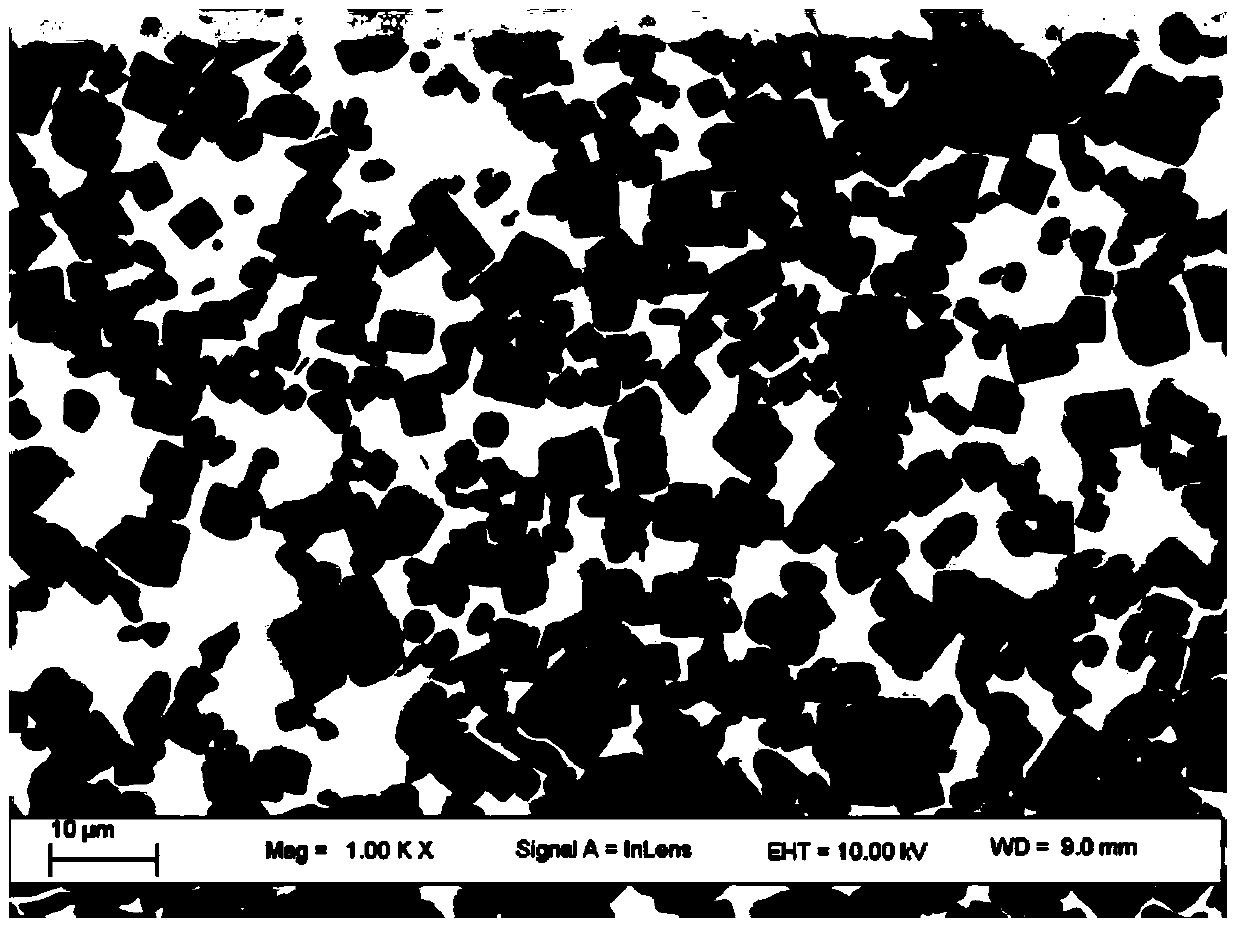

Embodiment 1

[0039] 1) Dilute 1ml of 10% chloroauric acid to 10ml of 1% chloroauric acid, add 24ml of toluene, and stir rapidly for 10min; 2) then pour 400mg of phase transfer reagent tetraoctylammonium bromide into step 1) to obtain In the solution, the toluene phase turns into dark orange, stir rapidly for 5-7min, and separate the toluene phase with a separatory funnel; 3) add a toluene solution containing 18 mg of mercaptoundecanoic acid to the toluene phase, and then add 5 mg / ml of Sodium borohydride solution (the total amount of sodium borohydride added in the whole process is 115mg), the toluene phase immediately turns dark brown, and stirs at high speed for 2-3h; 4) Wash the solution 3) obtained in step 3) with 25ml of deionized water, respectively. 5 times, the water phase in the solution was separated; 5) Pour the washed toluene phase into a 50ml round bottom flask, and after rotary evaporation at 55°C for 10-20min, a layer of black waxy initial product was obtained around the bott...

Embodiment 2

[0041] 1) Dilute 3ml of 10% chloroauric acid to 30ml of 1% chloroauric acid, add 24ml of toluene, and stir rapidly for 10min; 2) then pour 420mg of phase transfer reagent tetraoctylammonium bromide into step 1) to obtain In the solution, the toluene phase turns into dark orange, stir rapidly for 5-7min, and separate the toluene phase with a separatory funnel; 3) add a toluene solution containing 27 mg of mercaptoundecanoic acid to the toluene phase, and then add 5 mg / ml of Sodium borohydride solution (the total amount of sodium borohydride added in the whole process is 125mg), the toluene phase immediately turns dark brown, and stirred at high speed for 2-3h; 4) Wash the solution 3) obtained in step 3) with 25ml of deionized water respectively. 5 times, the water phase in the solution was separated; 5) Pour the washed toluene phase into a 50ml round bottom flask, and after rotary evaporation at 55°C for 10-20min, a layer of black waxy initial product was obtained around the bot...

Embodiment 3

[0043] 1) Dilute 2ml of 10% chloroauric acid to 20ml of 1% chloroauric acid, add 24ml of toluene, and stir rapidly for 10min; 2) then pour 350mg of phase transfer reagent tetraoctylammonium bromide into step 1) to obtain In the solution, the toluene phase turns into dark orange, stir rapidly for 5-7min, and separate the toluene phase with a separatory funnel; 3) add a toluene solution containing 4.5 mg mercaptoundecanoic acid to the toluene phase, and then add 5 mg / ml Sodium borohydride solution (the total amount of sodium borohydride added in the whole process is 105 mg), the toluene phase immediately turns dark brown, and stirred at high speed for 2-3h; 4) Wash the solution 3 obtained in step 3) with 25 ml of deionized water respectively -5 times, separate the water phase in the solution; 5) Pour the washed toluene phase into a 50ml round bottom flask, and after rotary evaporation at 55°C for 10-20min, a layer of black waxy initial product is obtained around the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com