Cu<2+>/Co<2+>/Ce<4+>/Ag<+>-doped ferric fluoride composite positive pole material and preparation method thereof

A composite positive electrode material and iron salt technology, which is applied in the direction of iron halide, battery electrodes, electrical components, etc., can solve the problems of not too good energy density, unsuitable for industrial applications, and low discharge voltage, so as to improve the discharge potential and comprehensive Electrochemical performance, effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

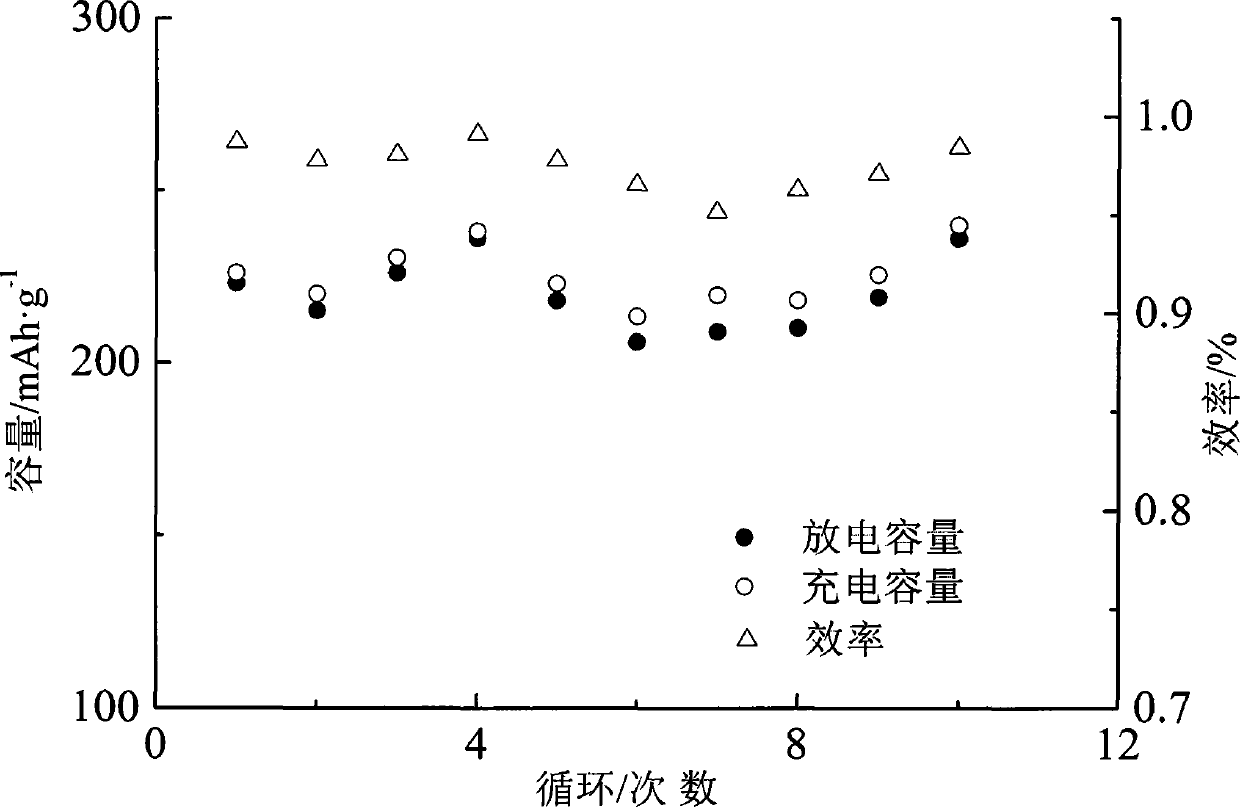

Image

Examples

Embodiment 1

[0022] Embodiment 1: Fe(NO 3 ) 3 9H 2 O and ammonium fluoride (molar ratio 1.0:3.1) and 3.2% by weight of Cu(C 2 o 4 )·0.5H 2 O, 3% Co(Ac) by weight 2 4H 2 O, the weight percent is 14% Ce (NH 4 ) 2 (NO 3 ) 6 , 4% by weight of AgNO 3 , 0.6% by weight of Tween-80 and 0.5% by weight of ethanol are ball milled at room temperature for 5 hours under the protection of high-purity nitrogen in a high-energy ball mill. After heating up to 450 degrees and keeping the temperature for 2 hours, cooling to prepare Cu 2+ ,Co 2+ , Ce 4+ , Ag + doped modified FeF 3 Cathode material.

Embodiment 2

[0023] Embodiment 2: FeCl 3 ·6H 2 O and ammonium fluoride (molar ratio 1.0:3.6) and 6% by weight of Cu(C 2 o 4 )·0.5H 2 O, the weight percentage is 15% Co (C 2 o 4 )·4H 2 O, the weight percentage is 3.5% Ce(NH 4 ) 2 (NO 3 ) 6 , 8% by weight of AgNO 3 , Span-60 with a weight percentage of 0.9% and ethanol with a weight percentage of 1.0% were ball milled at room temperature for 20 hours under the protection of high-purity nitrogen in a high-energy ball mill, and then the materials were taken out, and the temperature was raised under the protection of a mixed gas of 5% hydrogen and 95% argon After cooling to 400 degrees for 6 hours, the prepared Cu 2+ ,Co 2+ , Ce 4+ , Ag + doped modified FeF 3 Cathode material.

Embodiment 3

[0024] Embodiment 3: Fe 2 (SO 4 ) 3 9H 2 O and ammonium fluoride (molar ratio 1.0:3.5) and 15% by weight of Cu(NO 3 ) 2 ·3H 2 O, the weight percentage is 8% Co (C 2 o 4 )·4H 2 O, 6% by weight of Ce(NH 4 ) 2 (NO 3 ) 6 , 14% by weight of AgNO 3 1.5% by weight of Tween-80 and 2.0% by weight of ethanol were ball milled at room temperature for 10 hours under the protection of high-purity argon in a high-energy ball mill, and then the materials were taken out and protected by a mixed gas of 5% hydrogen and 95% argon. Heat up to 350 degrees and keep the temperature for 8 hours, then cool down to prepare Cu 2+ ,Co 2+ , Ce 4+ , Ag + doped modified FeF 3 Cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com