Detection test piece, manufacture method thereof and detection apparatus

A manufacturing method and test strip technology, which are applied in the field of test test strips and their manufacturing and detection devices, can solve the problems of increased use of enzymes or enzymes, high number of bits, user discomfort, etc., so as to improve the signal-to-noise ratio, The effect of reducing specification requirements and simplifying system architecture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

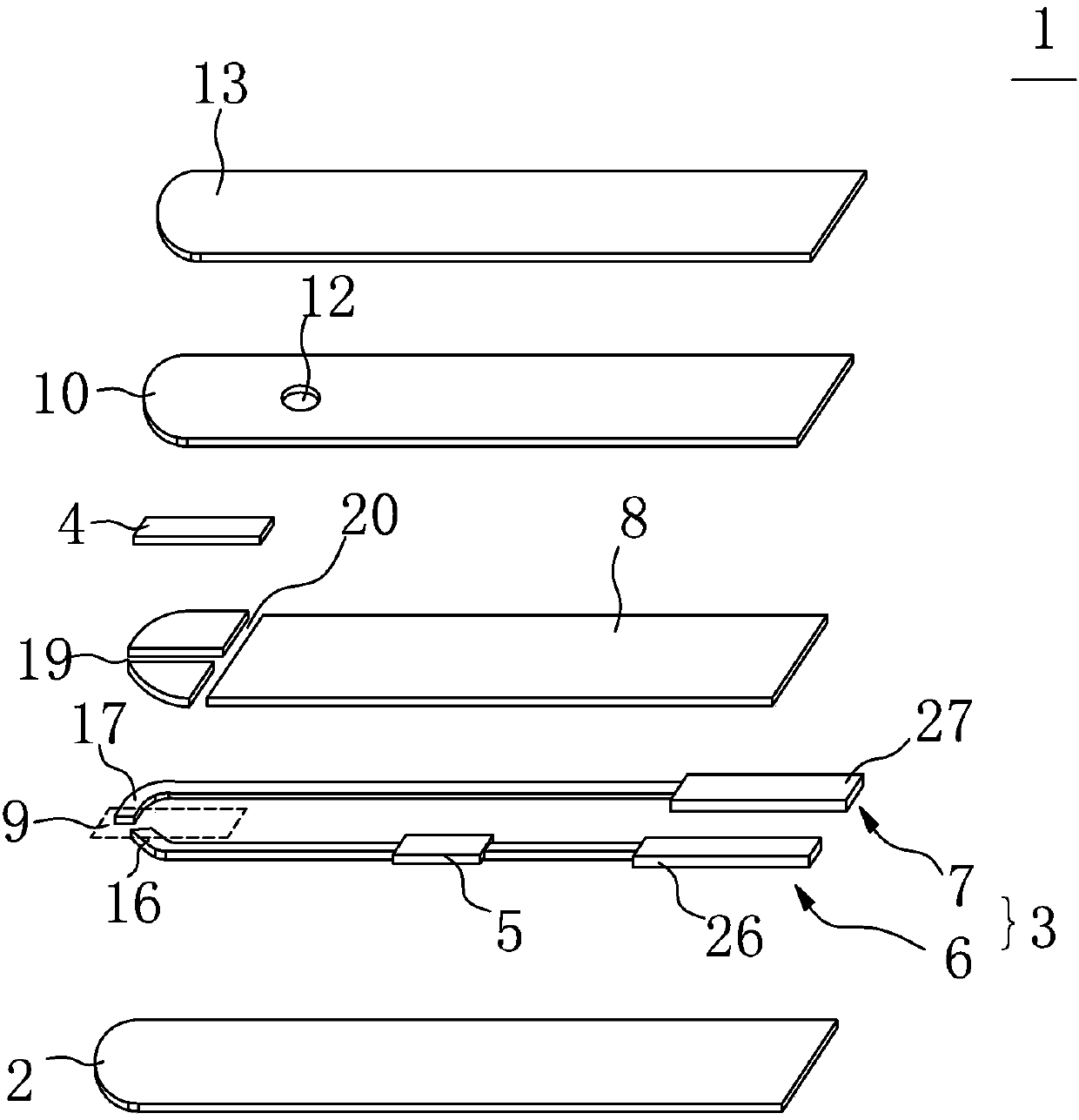

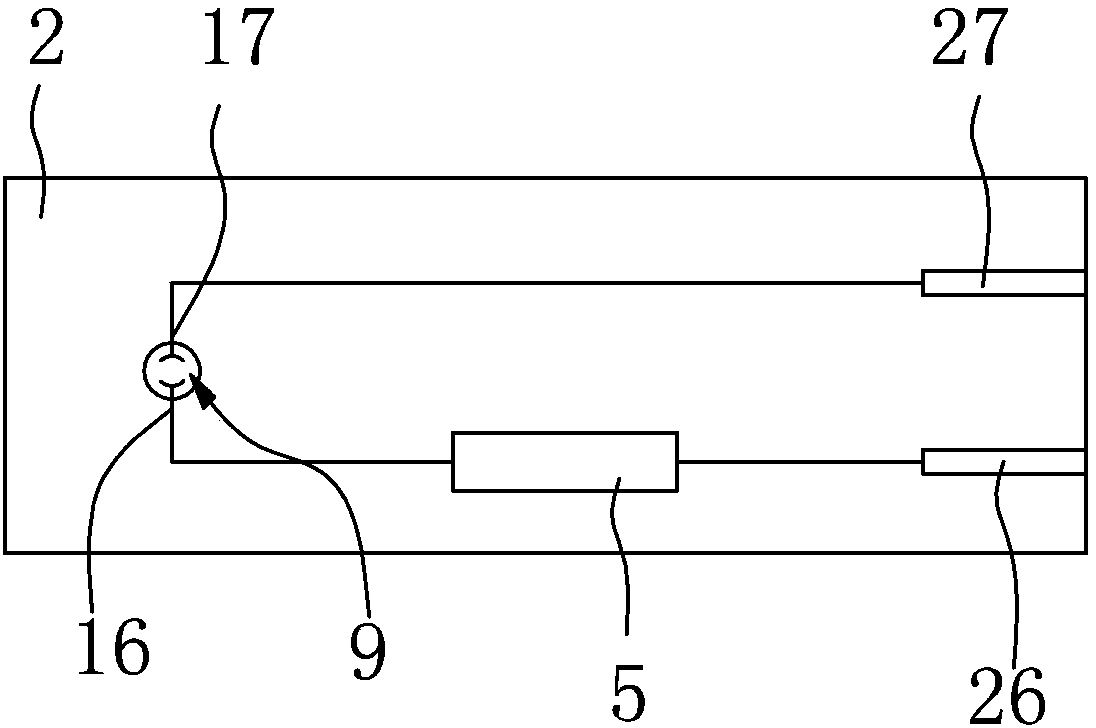

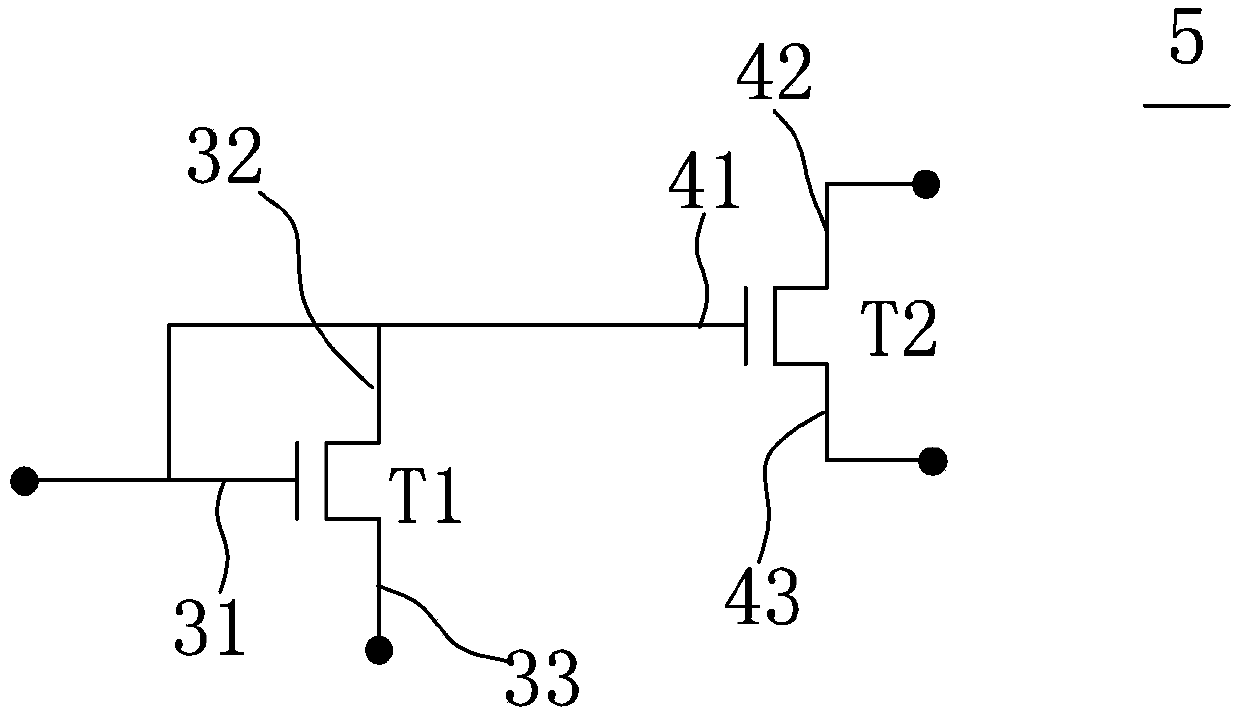

[0032] See Figure 1-Figure 2 , figure 1 as shown figure 1 Schematic diagram of the decomposition of the detection test piece in, figure 2 shown as figure 1Simplified schematic diagram of the assay strip in . The present invention provides a detection test piece 1 for detecting the content of biochemical components in a sample, wherein the detection test piece can be applied to an electrochemical detection test piece. The test strip 1 includes an insulating substrate 2 , an electrode layer 3 , a reaction layer 4 and an amplifier circuit 5 . In a specific embodiment, an insulating substrate 2 is used as the bottom plate of the test strip 1 . The insulating substrate 2 can be a soft material, such as an insulating polymer material; or a rigid material, such as ceramics, glass or glass fiber. Among them, examples of the insulating substrate 2 include, but are not limited to, polycarbonate, polyester, polyether, polyethylene terephthalate alcohol, polyamide, polyurethane, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com