Chitosan-iodine composite biomedical membrane and preparation method thereof

A biomedical and shell iodine technology, which is applied in the field of medical materials, can solve the problems such as the introduction of biological dressings that have not yet been discovered, and achieve superior hemostatic function, protect the wound surface, and improve the effect of the microenvironment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

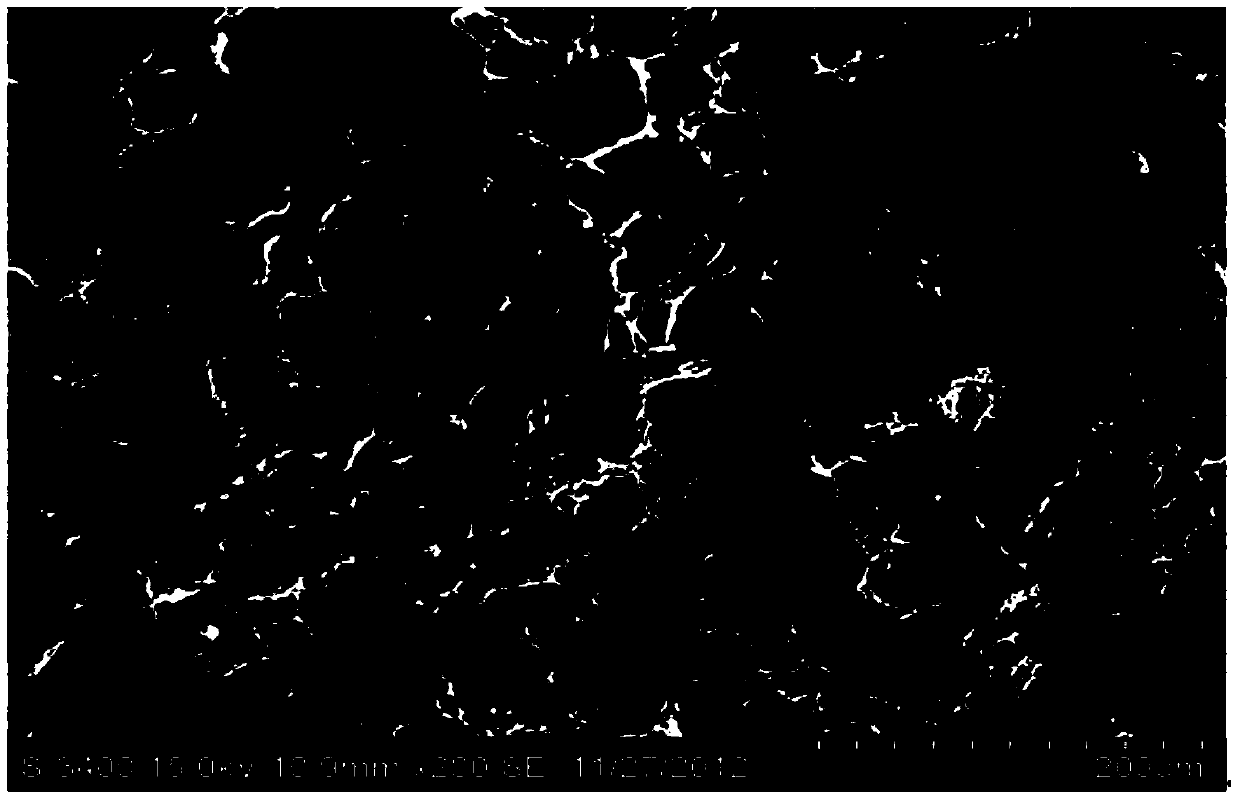

[0070] 1. The chitosan polyvinyl alcohol foam layer is composed of gelatin, chitosan and polyvinyl alcohol, and is prepared according to the following steps:

[0071] Ⅰ. Prepare a 1.0wt% gelatin solution, and heat it in a water bath at 50°C until it is completely dissolved;

[0072] Ⅱ. Add 1.0wt% polyvinyl alcohol to the above solution, and heat in a water bath at 90°C until completely dissolved;

[0073] Ⅲ. Add 0.6wt% chitosan, heat until completely dissolved

[0074] Ⅳ. Add 1.0wt% foaming agent and stir for 1 hour at a speed above 1000r / min;

[0075] Ⅴ. Add 0.8wt% glycerol and mix thoroughly;

[0076] Ⅵ. Add 0.01wt% glutaraldehyde and mix thoroughly;

[0077] Ⅶ. Gained chitosan polyvinyl alcohol foam is spread flat on a tetrafluoroethylene plate, and vacuum freeze-dried;

[0078] Ⅷ. Vacuum freeze-drying to obtain a molded foam, wash off unreacted glutaraldehyde, vacuum freeze-drying again, and obtain chitosan polyvinyl alcohol foam after drying;

[0079] Shell iodine, p...

Embodiment 2

[0095] 1. The chitosan polyvinyl alcohol foam layer is made up of gelatin, chitosan and polyvinyl alcohol, and is prepared as follows:

[0096] Ⅰ. Prepare a 3.0wt% gelatin solution, and heat it in a water bath at 50°C until it is completely dissolved;

[0097] Ⅱ. Add 5.0wt% polyvinyl alcohol to the above solution, and heat in a water bath at 90°C until completely dissolved;

[0098] Ⅲ. Add 0.8wt% chitosan, heat until completely dissolved

[0099] Ⅳ. Add 3.0wt% foaming agent and stir for 1 hour at a speed above 1000r / min;

[0100] Ⅴ. Add 2.0wt% glycerin and mix well;

[0101] Ⅵ. Add 0.1wt% glutaraldehyde and mix well;

[0102] Ⅶ. spread the obtained chitosan polyvinyl alcohol foam 0.3mm thick on the tetrafluoroethylene plate, vacuum freeze-drying;

[0103] Ⅷ. Vacuum freeze-drying to obtain a molded foam, wash off unreacted glutaraldehyde, vacuum freeze-drying again, and obtain chitosan polyvinyl alcohol foam after drying;

[0104] Shell iodine, polyvinyl alcohol and carbox...

Embodiment 3

[0120] The shell iodine composite biomedical film (i.e. shell iodine polyvinyl alcohol-polyvinyl alcohol-chitosan polyvinyl alcohol foam-polyglutamic acid reticular gel composite material) will be obtained, and the experimental group of 30 cases of the General Hospital of Chengdu Military Command The clinical trial with 30 cases of control groups proves that the shell iodine composite biomedical film with the shell iodine polyvinyl alcohol layer and the gel layer as the matrix provided by the present invention is used for wound dressings such as trauma wounds, surgical wounds, and burn wounds. Compared with the product prepared with application number 201310010441.5, it has more functions of protecting wound surface, absorbing exudate, stopping bleeding, preventing and controlling wound infection, and promoting wound healing, etc. It is safe and effective in clinical use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum aperture | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com