A method for stabilizing construction waste contaminated with various heavy metals

A construction waste and heavy metal technology, which is applied in construction waste recycling, waste treatment, solid waste removal, etc., can solve the problems of inapplicable heavy metal construction waste treatment and stabilization, restrictions on the subsequent use of construction waste, and high requirements for construction waste shredding. Achieve the effects of reducing potential environmental risks, lower requirements for crushing particle size, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

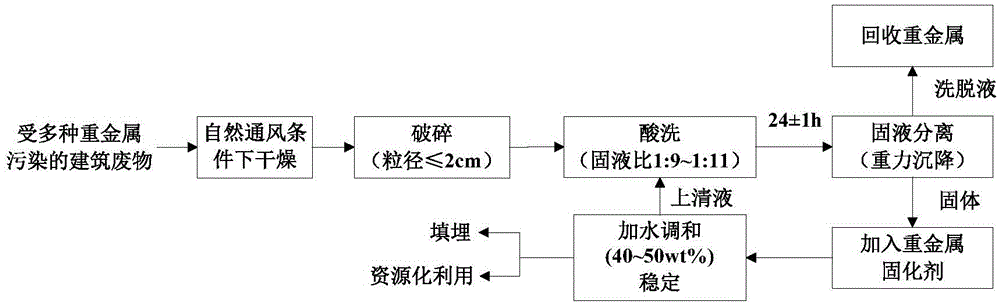

[0017] (1) The construction wastes, which are taken from the workshop of an industrial plant and polluted by various heavy metals, are laid flat under natural ventilation conditions until the apparent moisture disappears. Then, the construction waste samples are crushed by a jaw crusher, and crushed to The particle size is less than 2cm;

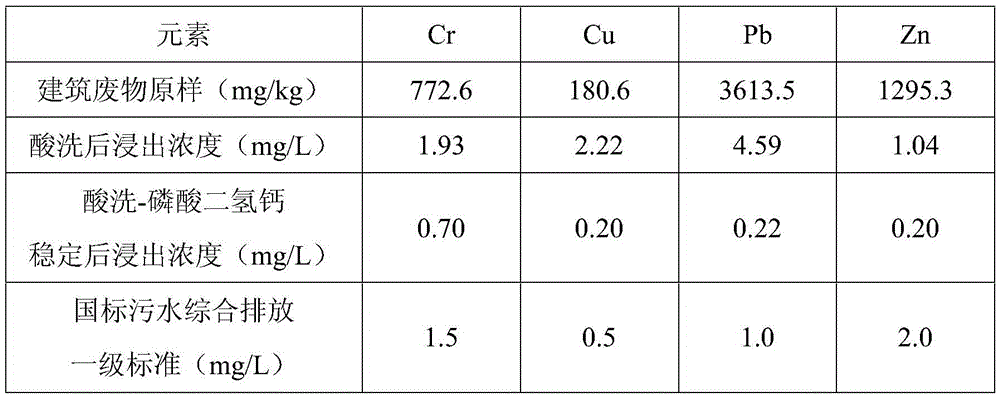

[0018] (2) Elution of heavy metals on the surface of construction waste with citric acid, solid-liquid separation after the contact time is 23-25 hours, the obtained eluate is discharged after the heavy metal recovery reaches the standard, and heavy metal solidifying agent calcium dihydrogen phosphate 20-25g / kg, and add 40-50 wt% water according to the mass of the construction waste to be stabilized, stir or shake at 30±5 rpm for 24 hours, let it stand under natural conditions, and stabilize for one week to obtain the pickling-stabilized construction waste and The supernatant liquid, the supernatant liquid is returned to the pickling proc...

Embodiment 2

[0024] (1) Take the construction waste contaminated with various heavy metals from the workshop of an industrial plant, lay it flat under natural ventilation conditions until the apparent moisture disappears, and then use a jaw crusher to crush the construction waste samples until the The particle size is less than 2cm;

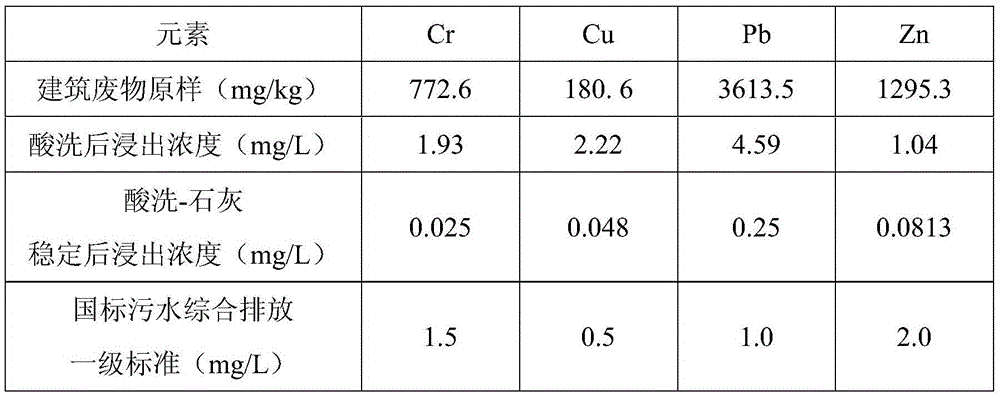

[0025] (2) Elution of heavy metals on the surface of construction waste with citric acid, solid-liquid separation after the contact time is 23 to 25 hours, the obtained eluate is discharged after the heavy metal recovery reaches the standard, and 20 to 25 g / kg of heavy metal solidifying agent lime is added to the solid, and Add 40-50wt% water according to the mass of the construction waste to be stabilized, stir or shake at 30±5rpm for 24 hours, then stand under natural conditions and stabilize for one week to obtain the pickled-stabilized construction waste and supernatant , the supernatant is returned to the pickling process, and together with the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com