Method for restoring clayed soil of high-load heavy metal polluted site

A technology of cohesive soil and remediation method, which is applied in the restoration of polluted soil and the removal of solid waste to achieve the effect of high degree of waste control, ecological restoration and strong universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

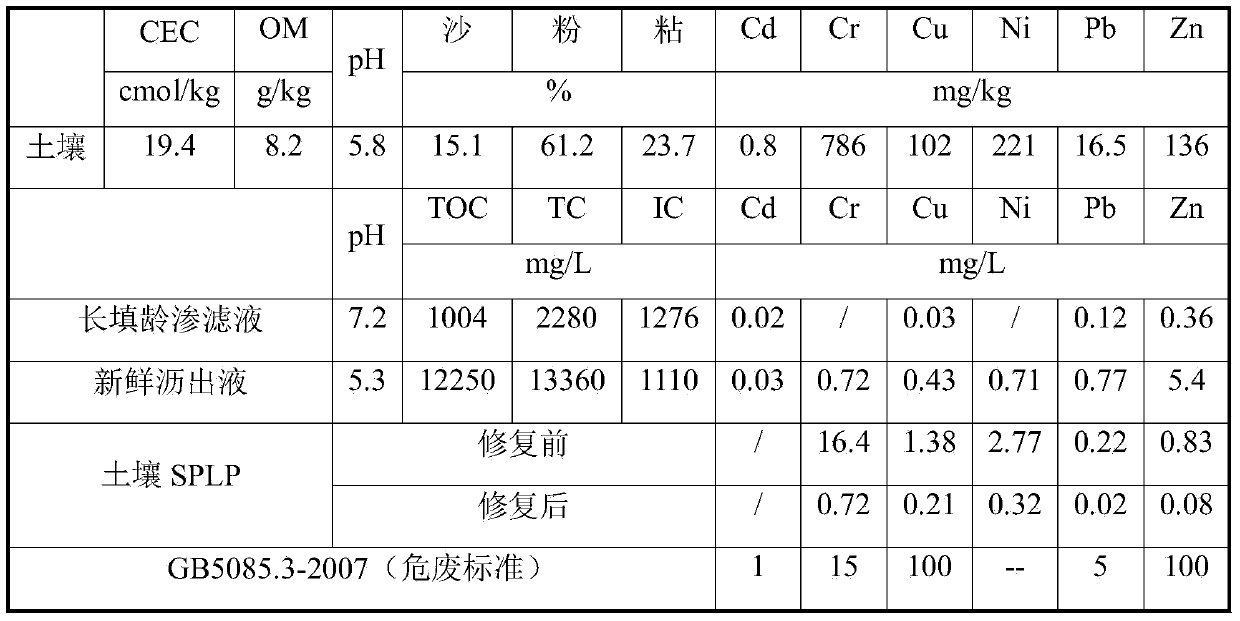

Embodiment 1

[0042] A kind of repairing method of cohesive soil of heavy metal polluted site with high load of the present embodiment, its specific steps are:

[0043] Step 1. Modification of contaminated soil

[0044] Preparation of slag powder: The slag was taken from a municipal solid waste incineration plant in East China. After aging for 30 days at room temperature, fine slag particles with a particle size of less than 5 mm were obtained by sieving; 0.05 mol / L hydrochloric acid was added to the It was pickled twice, each time for 10 minutes, then washed with water until neutral, dried and crushed to obtain slag powder;

[0045] Taking an electroplating site in East China as an example, the results of site investigation and risk assessment show that the type of contaminated soil is yellow-brown soil, and the main pollutants are heavy metals Cr and Ni; Stir and crush the soil with a crushing bucket so that more than 90% of the soil particles have a particle size of less than 2cm. After...

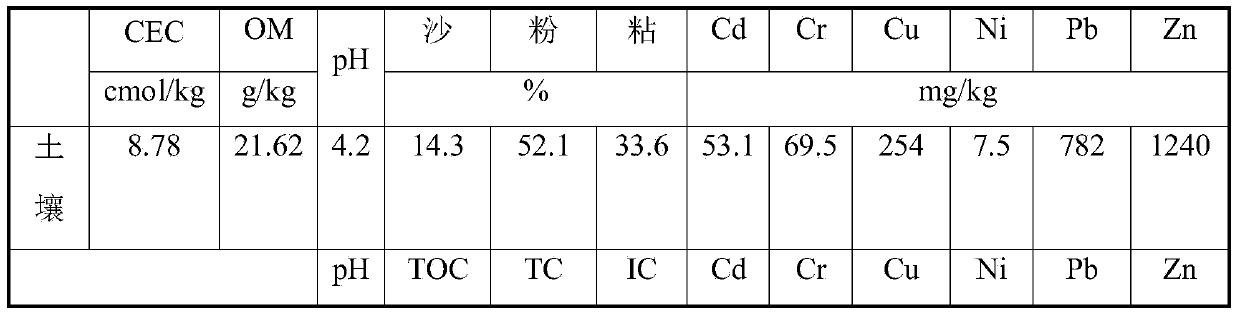

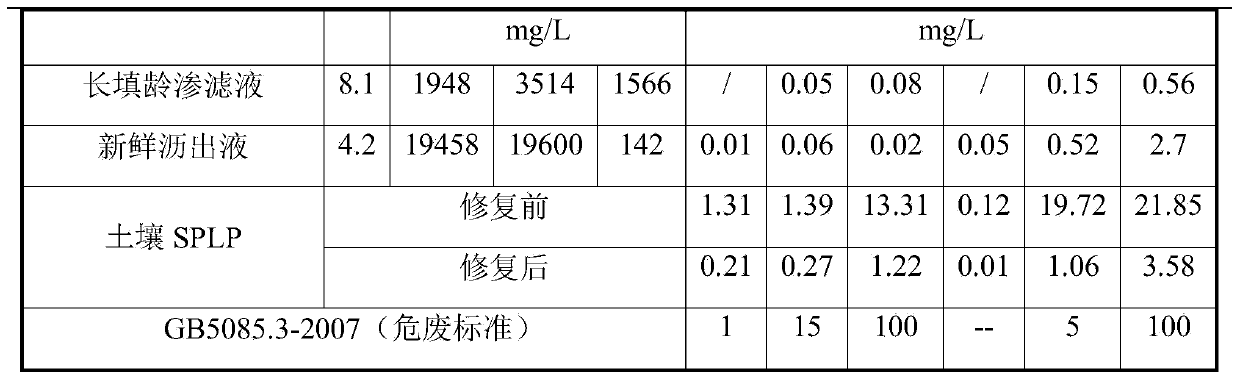

Embodiment 2

[0057] A kind of repairing method of cohesive soil of heavy metal polluted site with high load of the present embodiment, its specific steps are:

[0058] Step 1. Modification of contaminated soil

[0059] Preparation of slag powder: The slag was taken from a municipal solid waste incineration plant in central China, aged for 30 days at room temperature and sieved to obtain slag particles with a particle size of less than 5mm; 0.05mol / L of The slag particles are pickled twice with hydrochloric acid, each time for 20 minutes, then washed with water until neutral, dried and crushed to obtain slag powder, the particle size of the slag powder is between 0.05 and 2mm;

[0060] Taking a non-ferrous metal smelting site in central China as an example, the site investigation and risk assessment results show that the type of contaminated soil is red soil, and the main pollutants are heavy metals Cd, Cu, Pb and Zn; the contaminated soil is excavated in situ in the area to be restored , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com