Amphiprotic humic acid grafted copolymer coal water slurry dispersing agent as well as preparation and application thereof

A technology of graft copolymer and humic acid, which is applied in the direction of liquid carbon-containing fuel, petroleum industry, fuel, etc., can solve the problems of poor hydrophilicity, poor stability, and good dispersibility, so as to reduce surface free energy and achieve good adsorption effect , the effect of increasing the relative molecular mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

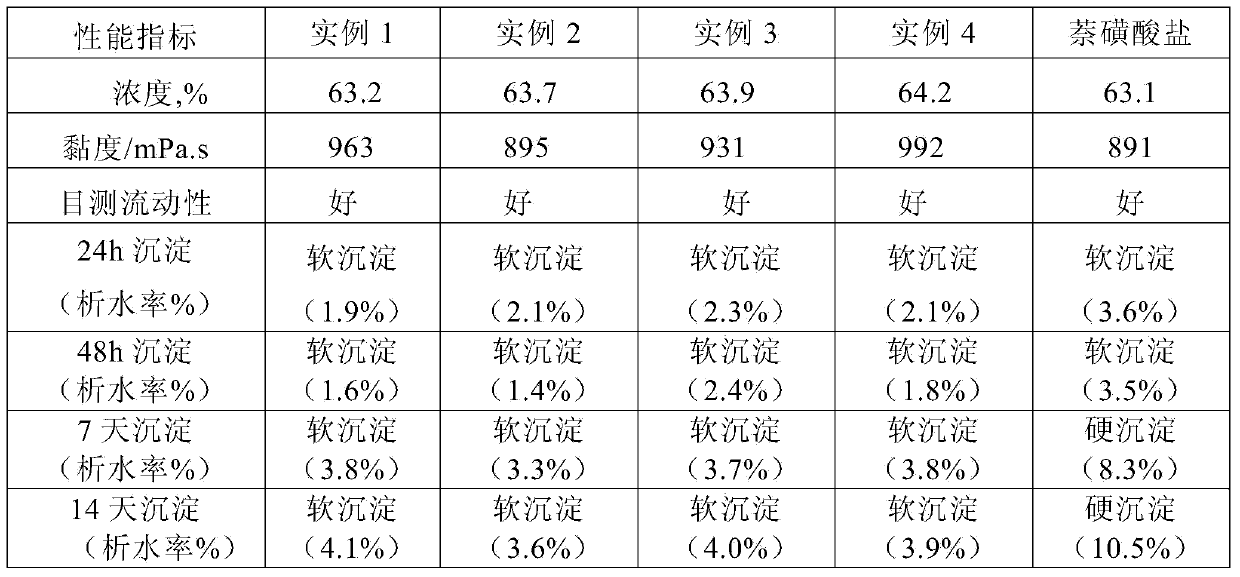

Examples

Embodiment 1

[0019] (1) Add 30g of humic acid and 70g of water into a three-necked flask equipped with a stirrer, condenser, dropping funnel and thermometer, then add 30% sodium hydroxide to adjust the pH to 9-10, and stir to dissolve.

[0020] (2) Dissolve 4g of allyl polyethylene glycol-400 in 40g of water, add 12g of sodium allyl sulfonate, 4g of methacryloxyethyltrimethylammonium chloride, stir and dissolve to obtain a mixed monomer solution ;

[0021] (3) when the humic acid aqueous solution of step (1) is warming up to 80 ℃, start to drop 20g mass fraction and be the mixed monomer solution that the potassium persulfate solution of 10% and step (2) prepare, control its rate of addition After 1 hour of dripping, keep the reaction for 2.5 hours after the dropwise addition.

[0022] (4) Cool the reactant to room temperature, filter and discharge the product, dry and pulverize the product to obtain a powdery amphoteric humic acid-based graft copolymer solid.

Embodiment 2

[0024] (1) Add 60 g of humic acid and 140 g of water into a three-necked flask equipped with a stirrer, condenser, dropping funnel, and thermometer, then add 30% sodium hydroxide to adjust the pH to 9-10, and stir to dissolve.

[0025] (2) Dissolve 6g of allyl polyethylene glycol-1000 in 40g of water, add 12g of sodium methacrylate, 2g of methacryloxyethyltrimethylammonium chloride, stir and dissolve to obtain a mixed monomer solution ;

[0026] (3) When the humic acid aqueous solution of step (1) is warming up to 75 DEG C, start to drop 24g mass fraction and be the ammonium persulfate solution of 10% and the mixed monomer solution prepared by step (2), control the rate of addition for 1h After dropping, keep warm for 4 hours after dropping.

[0027] (4) Cool the reactant to room temperature, filter the material, and dry and pulverize the product to obtain a powdery amphoteric humic acid-based graft copolymer solid.

Embodiment 3

[0029] (1) Add 30g of humic acid and 70g of water into a three-necked flask equipped with a stirrer, condenser, dropping funnel and thermometer, add 30% sodium hydroxide to adjust the pH to 9-10, and stir to dissolve.

[0030] (2) Dissolve 7.5g of allyl polyethylene glycol-800 in 40g of water, add 18g of sodium acrylate, 4.5g of methacryloxyethyltrimethylammonium chloride, stir and dissolve to obtain a mixed monomer solution;

[0031] (3) When the humic acid aqueous solution of step (1) is warming up to 75 DEG C, start to drop 36g mass fraction and be the ammonium persulfate solution of 10% and the mixed monomer solution prepared by step (2), control the rate of addition for 1h After dropping, keep warm for 4 hours after dropping.

[0032] (4) Cool the reactant to room temperature, filter the material, and dry and pulverize the product to obtain a powdery amphoteric humic acid-based graft copolymer solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com