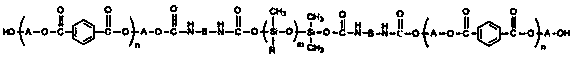

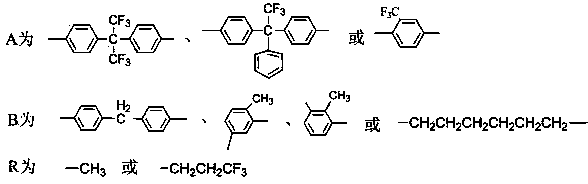

Fluorine-containing aromatic polyester-siloxane segmented copolymer as well as preparation method and application thereof

A technology of siloxane block and aromatic polyester, which is applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of separation membranes such as water resistance, solubility, and poor swelling, and achieve excellent hydrophobicity and lipophilicity. Effect of low surface energy and low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of hydroxyl-terminated aromatic polyester : First add 10.5g 1,1-bis(4-hydroxyphenyl)-1-phenyltrifluoroethane, 2.65g NaOH, 80ml deionized water and 0.051g phase transfer catalyst tetrabutyl Ammonium bromide, stirring to dissolve 1,1-bis(4-hydroxyphenyl)-1-phenyltrifluoroethane in water to form an inorganic phase. Dissolve 2.90 g each of terephthaloyl dichloride and isophthaloyl dichloride in 150 ml of dichloromethane to form an organic phase with a certain concentration. Drop the organic phase into the inorganic phase at a temperature of 10°C, stir and react for 1 hour, increase the temperature, stir and react below 20°C for 3 hours, then add dilute hydrochloric acid to wash to neutral, and obtain hydroxyl-terminated aromatic polyphenols after drying. Esters, using GPC-MwA gel chromatography, the number average molecular weight of the aromatic polyester was 26300.

[0040] Preparation of fluorine-containing aromatic polyester-siloxane block copolymer: th...

Embodiment 2

[0043] Preparation of hydroxyl-terminated aromatic polyester : First, add 10.14 g of bisphenol AF, 2.64 g of NaOH, 100 ml of deionized water and 0.045 g of phase transfer catalyst tetrabutylammonium bromide into a three-necked flask, and stir to dissolve bisphenol AF in water to form an inorganic phase. Dissolve 4.05g of terephthaloyl chloride and 2.03g of simple phthaloyl chloride in 150 ml of dichloromethane to form an organic phase with a certain concentration. Slowly drop the organic phase into the inorganic phase at a temperature of 5°C, stir and react for 2 hours, raise the temperature, and stir and react for 3.5 hours below 10°C. The product was washed with dilute hydrochloric acid until neutral, and after drying, the hydroxyl-terminated aromatic polyester was obtained. The number-average molecular weight of the hydroxyl-terminated fluorine-containing aromatic polyester was measured to be 48,000 by using GPC-MwA gel chromatography.

[0044] Preparation of fluorine-c...

Embodiment 3

[0047] Preparation of hydroxyl-terminated aromatic polyester : First add 20.32g of trifluoromethylhydroquinone, 2.60g of NaOH, 80 ml of deionized water and 0.06 g of phase transfer catalyst tetrabutylammonium bromide in the there-necked flask, and stir to dissolve the trifluoromethylhydroquinone It forms an inorganic phase in water. Dissolve 4.05g of terephthaloyl chloride and 2.03g of phthaloyl chloride in 150 ml of dichloromethane to form an organic phase with a certain concentration. Slowly drop the organic phase into the inorganic phase at a temperature of 10°C, stir and react for 5 hours, and react at a temperature below 10°C for 2 hours after the drop is complete. The product was washed with dilute hydrochloric acid to neutrality, and the hydroxyl-terminated aromatic polyester was obtained after drying. The number-average molecular weight of the hydroxyl-terminated fluorine-containing aromatic polyester was measured to be 17,000 by using GPC-MwA gel chromatography.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com