Preparing method of high-temperature antioxidant fastener and antioxidant material

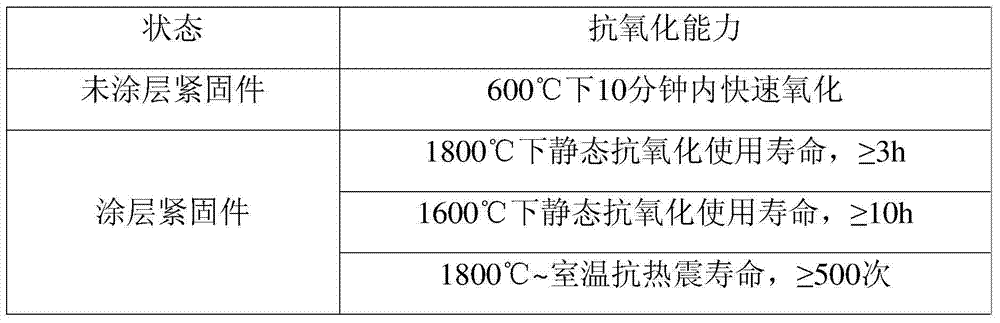

A high-temperature anti-oxidation and anti-oxidation technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of high brittleness, high cost, insufficient high temperature strength, etc. The effect of long life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

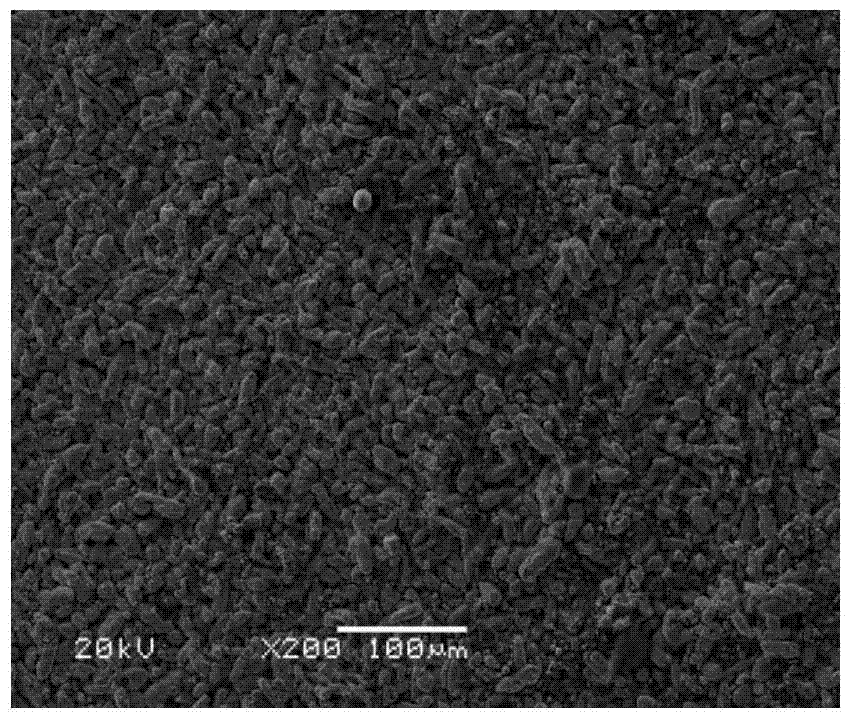

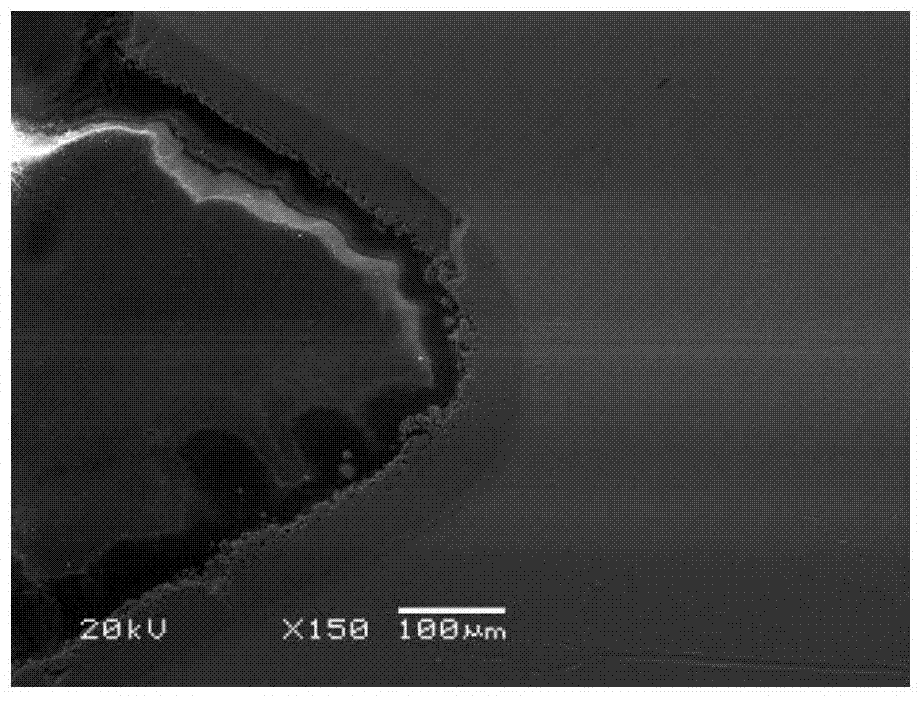

Image

Examples

Embodiment 1

[0026] High-temperature anti-oxidation materials contain the following components by weight percentage:

[0027] Cr is 3%, Ti is 7%, Mo is 12%, Y 2 o 3 2.5%, Al 2 o 3 5.5%, B 4 C is 0.8%, NaF is 0.2%, and the balance is Si.

[0028] 1) Fully mix the above powder with a particle size of 250 mesh, add PEG of 0.25Wt% of the powder as a binder, add ethanol twice the volume of the powder as a carrier, and ball mill at 230 rpm for 8 hours to prepare an antioxidant slurry material;

[0029] 2) The extruded ingot of φ125㎜ niobium-tungsten alloy (5%W-2%Mo-1%Zr, the balance is niobium) is forged four times to φ8.0 +0.1 mm (the bar needs to be pickled, annealed, sawed, etc. after each forging), and then made into φ8 after straightening, surface cleaning, polishing and vacuum annealing ±0.1 mm niobium tungsten alloy rod;

[0030] 3) Put φ8 ±0.1 The mm niobium-tungsten alloy bar is cold-forged to form a hexagonal head according to the conventional process, and then the niobium-tun...

Embodiment 2

[0037] High-temperature anti-oxidation materials contain the following components by weight percentage:

[0038] Si is 65%, Cr is 3%, Ti is 8%, Mo is 12%, Al2 o 3 5%, Y 2 o 3 3% for S, 2% for S, 0.3% for NaF, and 1.7% for V.

[0039] 1) Fully mix the above powder with a particle size of 250 mesh, add 0.25wt% PEG as a binder, add ethanol twice the volume of the powder as a carrier, and ball mill at 350 rpm for 8 hours to prepare an anti-oxidation slurry. The slurry was vacuum-dried and then ground and dispersed at a speed of 120 rpm for 2 hours to make an investment;

[0040] 2) The φ113㎜tantalum ten-tungsten alloy (10%W, the balance is Ta) ingot was forged 5 times to φ8.0 +0.1 mm, after each forging, pickling, annealing, sawing and other operations are required for the bar, and then it is made into φ8 after straightening, surface cleaning, polishing and vacuum annealing ±0.1 mm tantalum ten tungsten rod;

[0041] 3) Use the thread rolling machine according to the convent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com