Polyurethane resin composition for printing ink binder

A polyurethane resin and composition technology, applied in polyurea/polyurethane coatings, inks, applications, etc., can solve the problems of poor water resistance, alcohol resistance, exudation, residual solvents, etc., and achieve excellent printing properties and printing adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

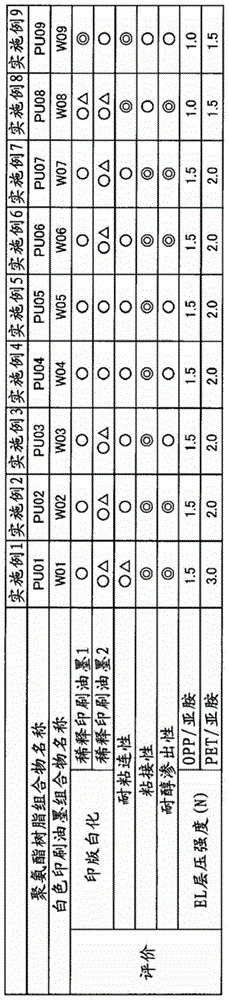

Examples

Embodiment

[0065] Hereinafter, although an Example is given and the embodiment of this invention is described in detail, this invention is not limited to these Examples. Hereinafter, "parts" and "%" represent "parts by weight" and "% by weight" unless otherwise noted.

[0066] It should be noted that the hydroxyl value is calculated by converting the amount of hydroxyl groups in 1 g of the resin into mg of potassium hydroxide by acetylating the hydroxyl groups in the resin with an excess acetylating reagent and back-titrating the remaining acid with a base. The value thus obtained; and the value measured in accordance with JIS K0070. The amine value is the number of mg of potassium hydroxide equivalent to the hydrochloric acid equivalent required to neutralize the amino groups contained in 1 g of the resin. The acid value is the number of mg of potassium hydroxide required to neutralize the acid groups contained in 1 g of the resin. The measurement method may be a known method, and gene...

Synthetic example 1

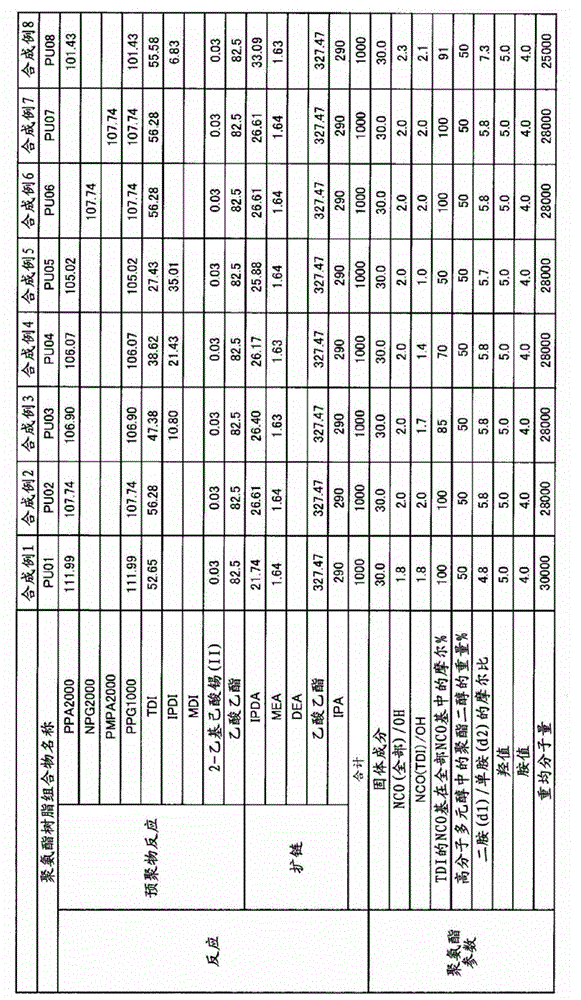

[0072] Into a four-necked flask equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen gas introduction tube, 111.99 parts of PPA2000 (hydroxyl value 56.1 mgKOH / g) with a molecular weight of 2000 and 111.99 parts of PPG1000 (hydroxyl value 112.2 mgKOH / g) with a molecular weight of 1000 were added , 52.65 parts of toluene diisocyanate, 0.03 parts of tin (II) 2-ethylhexanoate, and 82.5 parts of ethyl acetate were reacted at 90° C. for 3 hours under a nitrogen stream to obtain 359.16 parts of a solution of a terminal isocyanate prepolymer. Next, 21.74 parts of isophoronediamine, 1.64 parts of monoethanolamine, 290 parts of isopropanol, and 327.47 parts of ethyl acetate were mixed, and 359.16 parts of the obtained solvent solution of the terminal isocyanate prepolymer was added to the mixed material. Parts were slowly added at room temperature, followed by reaction at 50° C. for 1 hour to obtain a polyurethane resin composition (PU01) with a solid content of 30....

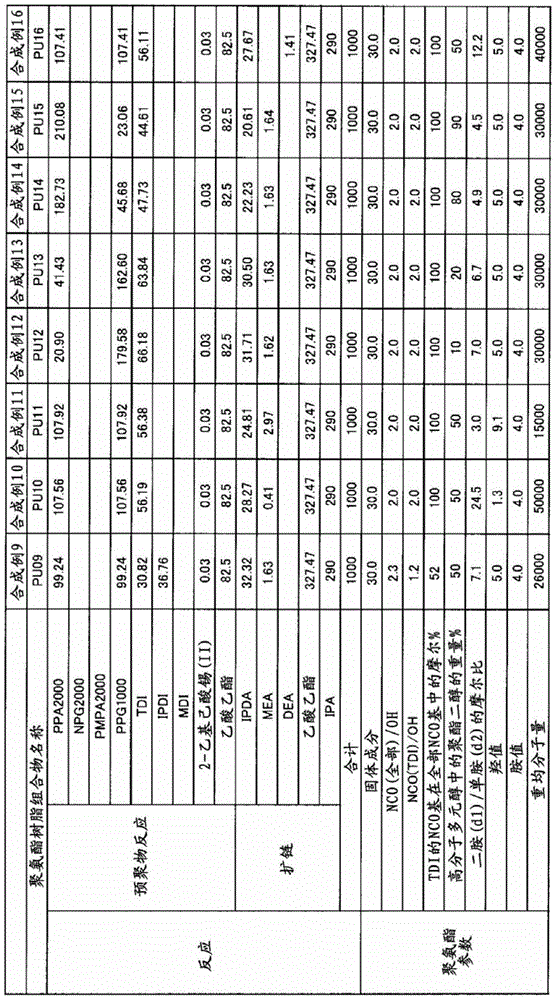

Synthetic example 2~26

[0074] Urethane resin compositions (PU02 to PU26) were obtained by the same operation as in Synthesis Example 1 using the addition ratios in Tables 1 to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com