Low temperature plasma coating for anti-biofilm formation

A plasma and biofilm technology, which is applied in the field of low temperature plasma coating against biofilm formation, and can solve problems such as odor problems, pipes, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1. TMS coated SS and Ti substrates

[0061]SS and Ti substrates. 316L SS and high-strength Ti (grade 5, also known as Ti-6A1-4V because of the addition of aluminum and vanadium alloying elements) coupons with a size of about 10mmx10mmx1mm were used in an ultrasonic bath at 50°C for 3 % (v / v) detergent 8 (Alconox, Inc., White Plains, NY, USA) solution for washing for 3 hours. During washing, samples were removed from the solution every 30 min, rinsed with distilled water, and placed in fresh detergent solution. After washing, the metal coupons were rinsed with acetone and blotted dry with Kimwipes.

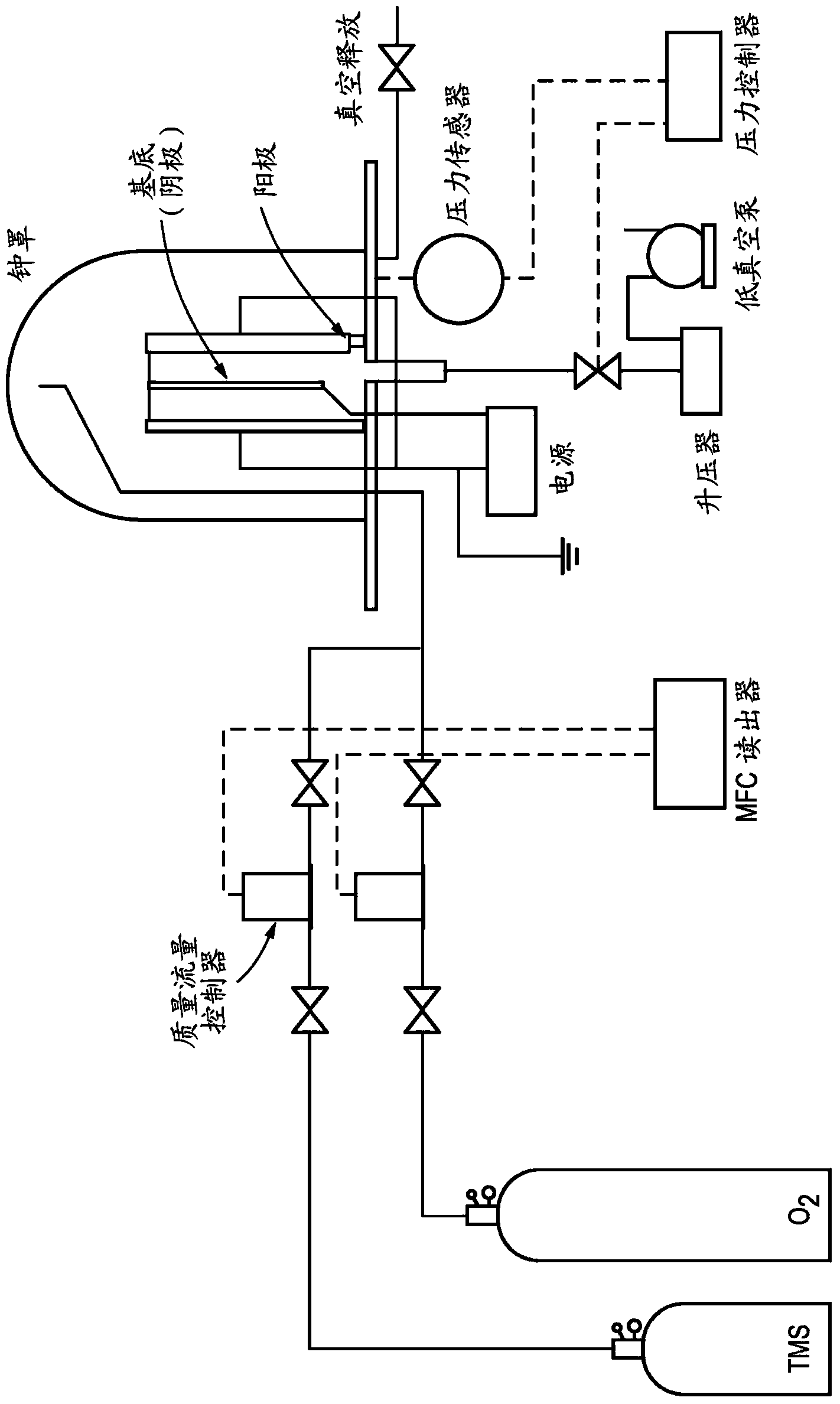

[0062] TMS plasma coating on SS and Ti flakes. The coupon was then bonded to an aluminum plate with a surface area of 15.3cmx7.6cm using silver epoxy. Additionally, silicon flakes were bonded to aluminum panels for coating thickness evaluation. The plates were then placed into an 801 bell jar reactor. The plate is placed between two SS or Ti plates. In this ...

Embodiment 2

[0082] Embodiment 2.TMS / O 2 Coated SS and Ti substrates

[0083] The washed-step SS and Ti flakes were then fixed on sample holders made of aluminum strips and stainless steel rods using small clips. Additionally, silicon flakes were mounted on sample holders for coating thickness evaluation. Then put the sample holder into the 80 1 bell jar reactor. The bracket is positioned between two titanium plates. In this configuration, the lamella and sample holder serve as cathodes, while the two outer titanium plates serve as electrically grounded anodes. This arrangement is a typical substrate-as-electrode type arrangement, where the sample to be modified is used as the working electrode (cathode). In this scheme, the electrodes were connected to the output section of an MDX-1K magnetron driver (Advanced Energy Industries, Inc., Fort Collins, CO, USA) used as a DC power supply. The whole reactor setup is as figure 1 , which shows the electrode arrangement in relation to the ar...

Embodiment 3

[0085] Example 3. Attachment and colonization of S. epidermidis on TMS-coated SS and Ti wafers.

[0086] S. epidermidis strain ATCC35984 / RP62A was isolated from a patient with device-associated sepsis. This strain proved to be a high biofilm producer. RP62A is kindly provided by NARSA (Network on Antimicrobial Resistance in Staphylococcus aureus program) supported by NIAID and NIH contract number HHSN272200700055C.

[0087] Biofilm formation assay. Biofilm formation was first measured by crystal violet (CV) staining. Four sets of 1x1 cm flakes (SS uncoated, SS TMS coated, Ti uncoated and Ti TMS coated) were used for this experiment. Each side of the wafer was sterilized with a UV lamp at a wavelength of 253.7 nm for 20 minutes and then coated with 20% (v / v) human plasma in 50 mM carbonate buffer (pH 9.5) overnight. One capsule content of carbonate-bicarbonate buffer (Sigma-Aldrich, St. Louis, MO) was dissolved in 80 ml of distilled and deionized water and mixed with 20 ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com