Garlic oil softgel and preparation method thereof

A technology of garlic oil and soft capsules, which is applied in food preparation, capsule delivery, and pharmaceutical formulations, etc., can solve the problems of not being able to give full play to the medical and health effects of garlic, the reduction of medical and health effects, and the inability to eat conveniently. Diseases of the vascular system, delay and prevention effects, effects of improving the body's immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

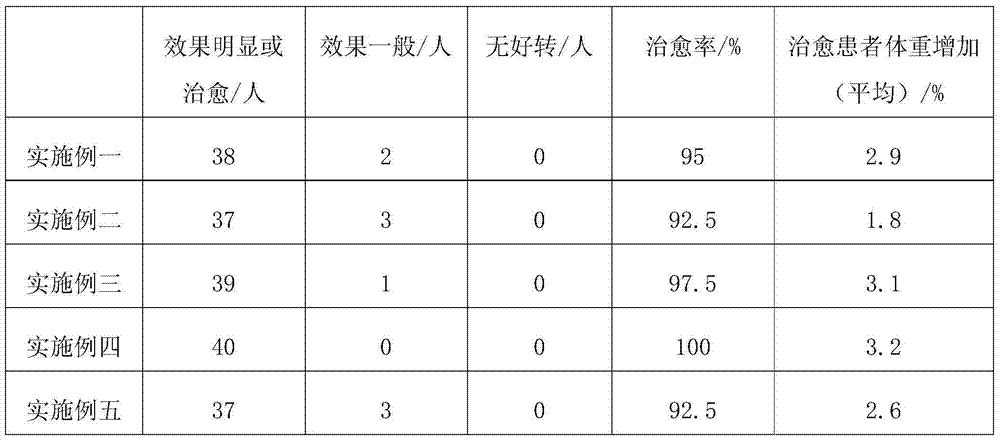

Examples

Embodiment 1

[0022] A preparation method for garlic oil soft capsules, comprising the following steps,

[0023] (1) Extraction of garlic oil: take fresh and washed garlic and add it to the extraction axe, use ethanol of 5% by weight of the raw material as entrainer, according to the extraction pressure of 5 MPa, the extraction temperature is 20°C, and the garlic oil is obtained after extraction for 1 hour, which is set aside ;

[0024] (2) Preparation of contents: Weigh 2 parts of corn germ oil and 2 parts of linoleic acid in ethanol and dissolve them in ethanol, add 1 part of vitamin C, 3 parts of rutin, and 0.5 part of vitamin P during stirring, and mix well Then add 20 parts of garlic oil dissolved in ethanol, stir for 3 hours under airtight conditions, let stand for 10 hours, and filter the solution to obtain a filter cake. Dried to obtain the contents of the capsule;

[0025] (3) Preparation of capsule shell: Weigh 10 parts of cornstarch in parts by weight, add 40 parts of water, mi...

Embodiment 2

[0028] A preparation method for garlic oil soft capsules, comprising the following steps,

[0029] (1) Extraction of garlic oil: get fresh, washed garlic and add it to the extraction axe, use ethanol with 5% of raw material weight as the entrainer, according to the extraction pressure is 15MPa, the extraction temperature is 25°C, and the garlic oil is obtained after extraction for 1.5h. spare;

[0030] (2) Preparation of the content: Weigh 5 parts of corn germ oil and 5 parts of linoleic acid in ethanol and dissolve them in ethanol, add 5 parts of vitamin C, 5 parts of rutin and 2 parts of vitamin P during stirring, mix well and then add 40 parts of garlic oil dissolved in ethanol, stirred for 5 hours under airtight conditions, then stood still for 18 hours, filtered the solution to obtain a filter cake, washed with water, and dried under vacuum at a temperature of 60°C, a pressure of 3 MPa, and a time of 6.5 hours to obtain capsule contents;

[0031] (3) Preparation of caps...

Embodiment 3

[0034] A preparation method for garlic oil soft capsules, comprising the following steps,

[0035] (1) Extraction of garlic oil: get fresh, washed garlic and add it to the extraction axe, use ethanol with 5% of raw material weight as entrainer, according to extraction pressure is 10MPa, extraction temperature is 23 ℃, after extraction 1.3h, garlic oil is obtained, spare;

[0036] (2) Preparation of contents: Weigh 3 parts of corn germ oil and 3 parts of linoleic acid in ethanol by weight, add 3 parts of vitamin C, 4 parts of rutin, and 1.2 parts of vitamin P during stirring, and mix well Then add 30 parts of garlic oil dissolved in ethanol, stir for 4 hours under airtight conditions, let it stand for 15 hours, filter the solution to obtain a filter cake, and wash it with water at a temperature of 50° C., a pressure of 1.5 MPa, and a time of 4.5 hours. Vacuum drying to obtain the contents of the capsule;

[0037](3) Preparation of capsule shell: Weigh 13 parts of cornstarch b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com