Normal-temperature dispersion method for water-soluble oxidant in macromolecular material

A technology for polymer materials and oxidants, which is applied in the field of room temperature dispersion of water-soluble oxidants in polymer materials, can solve the problems of long dispersion time of oxidants, poor dispersion uniformity and stability, and many processes, and achieves easy process control and dispersion. The effect of small particle size and safe process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Dispersion was carried out in a reactor with a volume of 1 liter. Nitrocellulose with a nitrogen content of 12.6% is used as the raw material of the polymer material. First, the nitrocellulose is added to the reactor, and then it is added into an ethyl acetate solvent 10 times the mass of the nitrocellulose under stirring. Stir and dissolve for 30min to obtain a polymer sol containing nitrocellulose, then continuously add an aqueous solution of ammonium perchlorate that has a mass concentration of 10% dissolved in advance in the polymer sol containing nitrocellulose under stirring, namely The oxidizing agent is ammonium perchlorate. The amount of ammonium perchlorate solution added is 0.4 times the volume of ethyl acetate solvent used to dissolve nitrocellulose. Stir continuously at room temperature for 30 minutes to 60 minutes. After fully emulsifying, the inner phase is Polymer emulsion of ammonium perchlorate aqueous solution. Then, the polymer emulsion was added in...

Embodiment 2

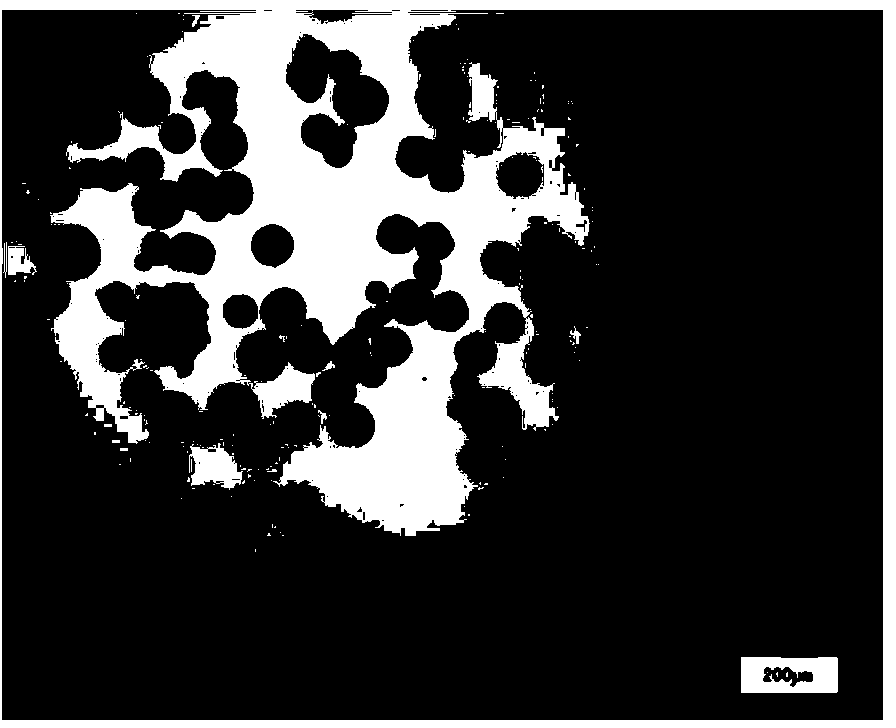

[0049] Using the same process as in Example 1, select nitrocellulose with a nitrogen content of 12.6% as a raw material, use ammonium perchlorate as an oxygenant, and have a solvent ratio of 10, and the mass concentration of the ammonium perchlorate aqueous solution added in the emulsification process is 10 %, the add-on is 0.2 times of the used solvent volume, and the ammonium perchlorate aqueous solution volume used for dispersion is 1.5 times of the used solvent volume, and other operating parameters are the same as in Example 1, and the content of ammonium perchlorate in the test containing energetic composite particles is 16.5%, the average diameter of ammonium perchlorate dispersed in the sample measured by electron microscope is 2.5 μm, after dissolving the energetic composite particles with ethyl acetate, apply them to a glass slide and observe the particle size distribution of ammonium perchlorate by optical microscope Such as figure 2 shown. It can be seen from the...

Embodiment 3

[0051] Adopting the same process as in Example 1, selecting nitrocellulose with a nitrogen content of 13.0% as a raw material, using ammonium perchlorate as a water-soluble oxidizing agent, the solvent ratio is 2, the quality of the ammonium perchlorate aqueous solution added in the emulsification process The concentration is 10%, and the addition is 0.6 times of the volume of the solvent used. The aqueous oxidant solution used for dispersion is changed to the mother liquor recovered in Example 1. The volume of the mother liquor is 1 time of the volume of the solvent used. Other operating parameters are the same as in Example 1. The test contains The content of ammonium perchlorate in the energy composite particle is 12.1%, and the average diameter of ammonium perchlorate dispersed in the sample is 2.8 μm as measured by electron microscope. From the above results, it can be seen that the particle size of the ammonium perchlorate particles dispersed in the prepared energetic com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com