Silicon dioxide antireflection coating liquid, preparation method of silicon-dioxide antireflection coating liquid and application of silicon-dioxide antireflection coating liquid in polyester fabrics

An anti-reflection coating, silica technology, applied in textiles and papermaking, fiber treatment, fiber type, etc., can solve the problem of decline; Chinese invention patent application, no porous structure, particle interconnection, etc., to achieve fabric feel Small impact, simple and easy operation, and the effect of reducing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weigh 10g of ethanol and add it to 30g of commercial silicon dioxide aqueous dispersion (solid content is 50%, the average particle diameter of silicon dioxide particles is 20nm), after mechanical stirring and mixing, the solution is added to 100mL jacketed reaction In the container, the temperature began to rise. After the temperature reached 40°C, 2.5 g of tetraethoxysilane was added thereto, and the pH of the solution was adjusted to 6 with acetic acid, and the reaction started. After reacting for 24 hours, a silicon dioxide anti-reflection coating liquid composed of the condensation product 1 of tetraethoxysilane and silicon dioxide was prepared, with a solid content of 37.5%.

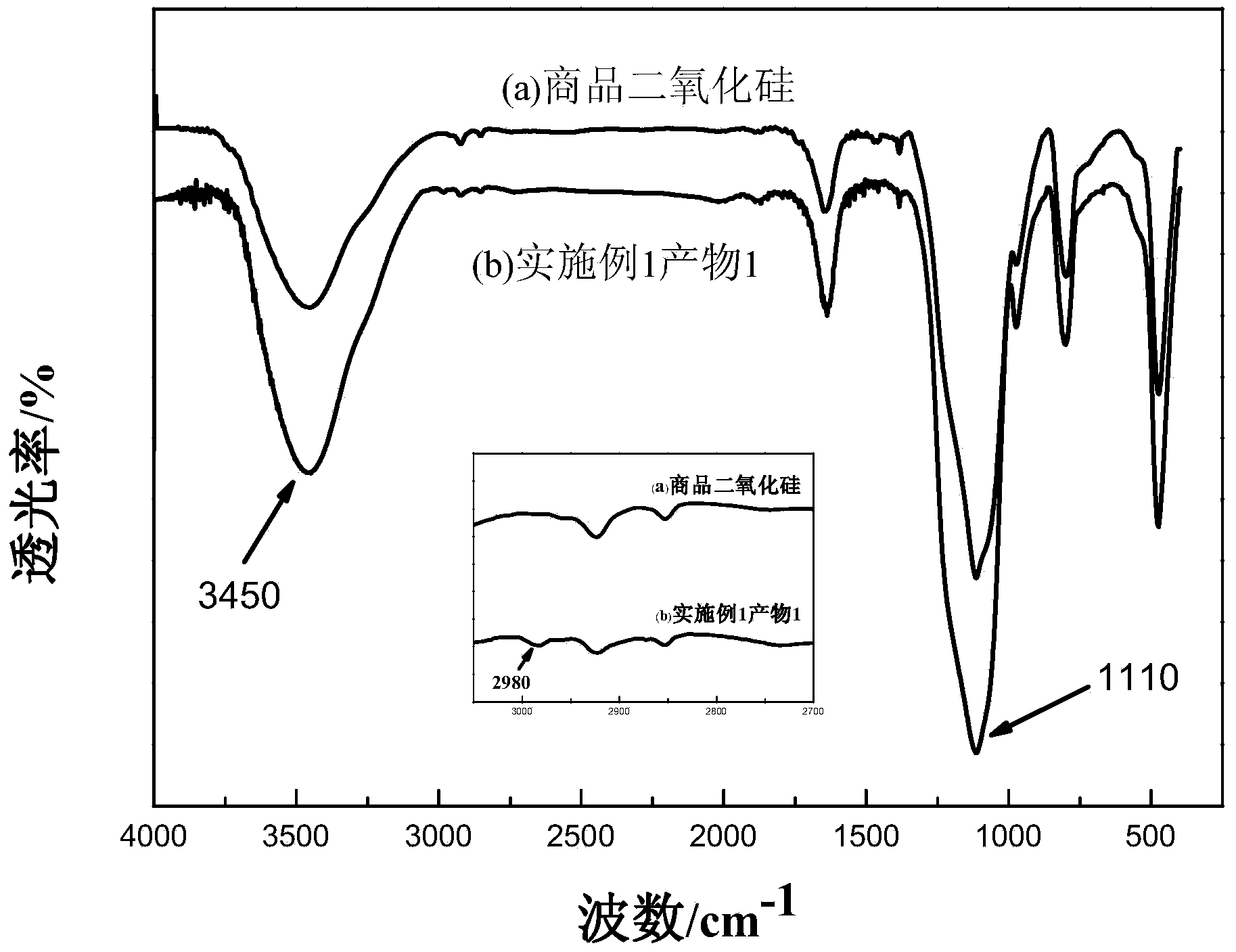

[0045] The product 1 was centrifuged-washed five times to remove the input but unreacted substances, and the white powder of the product 1 obtained after vacuum drying was analyzed by KBr tablet method, and its infrared analysis spectrum was as follows: figure 1 shown. The chemical structur...

Embodiment 2

[0047] Weigh 20g of ethanol and add it to 50g of commercial silicon dioxide aqueous dispersion (solid content is 50%, the average particle diameter of silicon dioxide particles is 20nm), after mechanical stirring and mixing, the solution is added to 250mL jacketed reaction 5 g of methyltrimethoxysilane was added thereto after the temperature reached 25° C., and the pH of the solution was adjusted to 5 with formic acid. After reacting for 20 hours, a silicon dioxide anti-reflection coating liquid composed of the condensation product 2 of methyltrimethoxysilane and silicon dioxide was prepared, with a solid content of 35.7%.

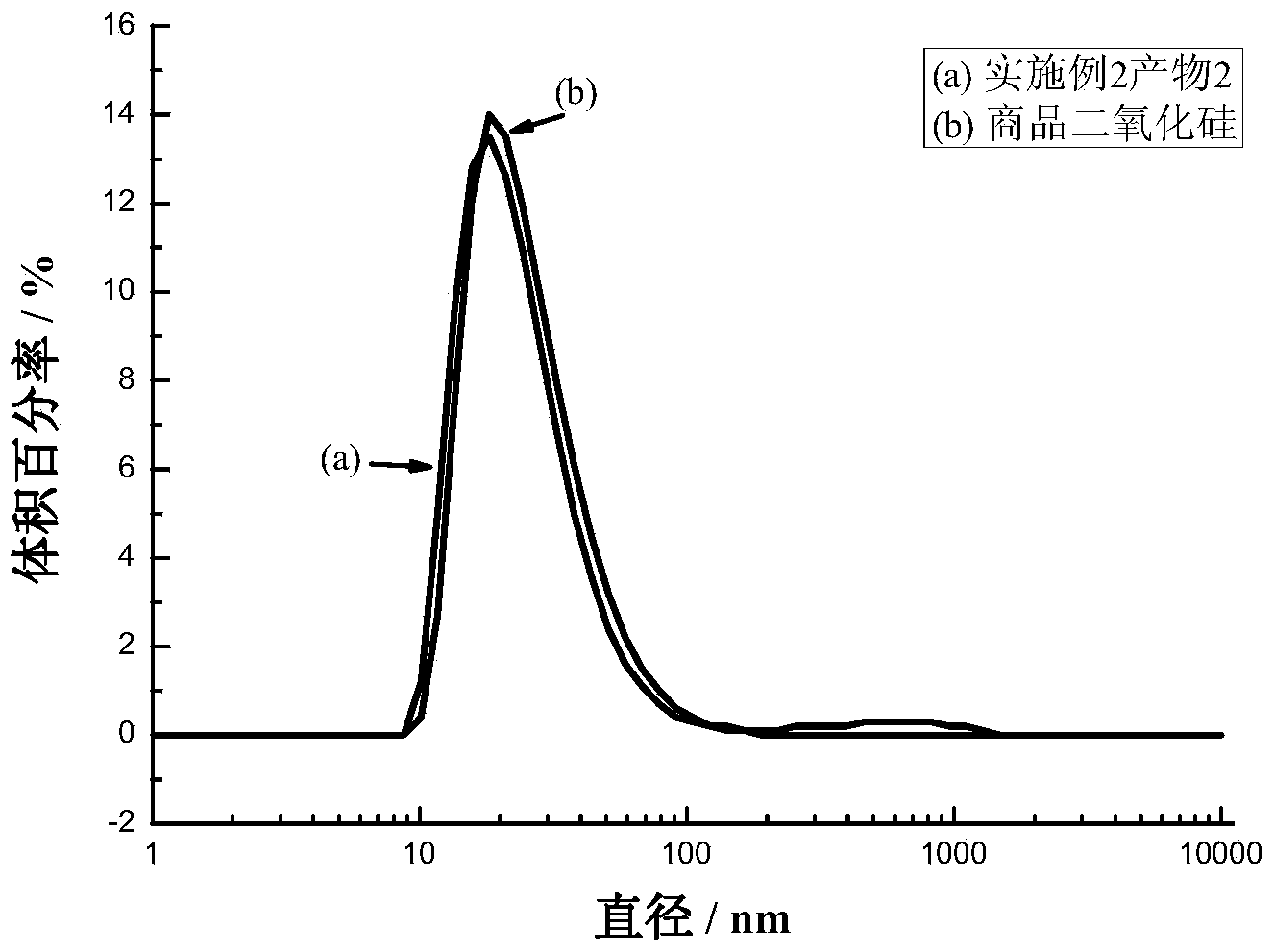

[0048] After diluting the product 2 and the commercial silica, the particle size distribution curve was measured respectively by a Malvern nanometer particle size analyzer, as shown in figure 2 shown. The particle size of the product 2 modified by the silane coupling agent and the commercial silica are both about 20nm, and the particle size distribution ...

Embodiment 3

[0050] Weigh 8g of ethanol and add it to 65g of commercial silicon dioxide aqueous dispersion (solid content is 50%, the average particle diameter of silicon dioxide particles is 20nm), after mechanical stirring and mixing, the solution is added to 250mL jacketed reaction 3.25 g of tetramethoxysilane was added thereto after the temperature reached 40° C., and the pH of the solution was maintained at 7 without adding acid. After reacting for 24 hours, a silicon dioxide anti-reflection coating liquid composed of the condensation product 3 of tetramethoxysilane and silicon dioxide was obtained, with a solid content of 44.5%.

[0051] image 3 It is a transmission electron micrograph of commercial silica, and the transmission electron micrograph of tetramethoxysilane and silica condensation product 3 that embodiment 3 obtains is as follows: Figure 4 shown. Depend on image 3 with Figure 4 It can be seen that product 3 has no obvious difference in nanoparticle morphology comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com