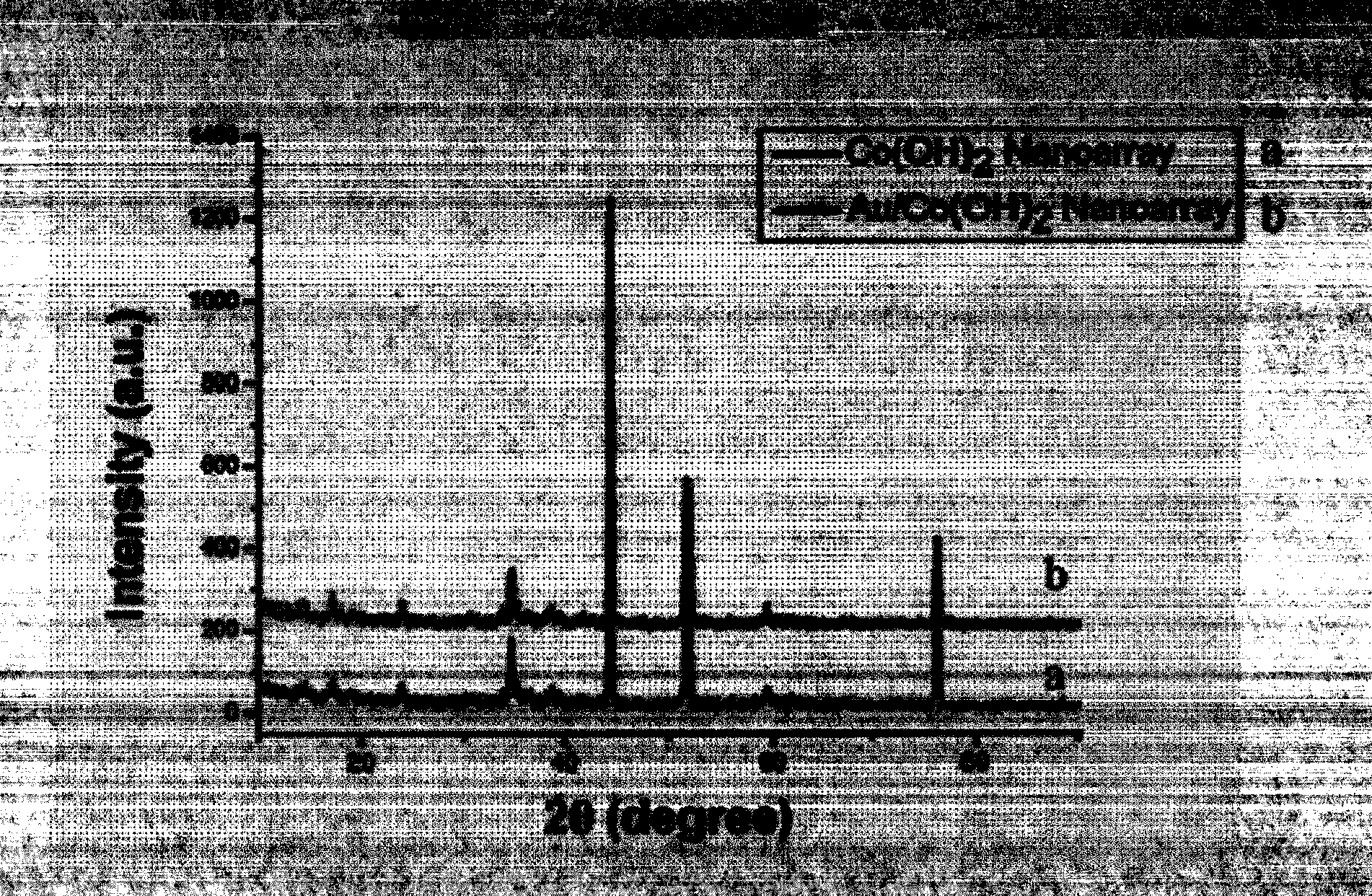

Au/Co(OH)2 nano-array structured catalyst

A structured catalyst and nano-array technology, which is applied in the field of catalysis, can solve the problems of less research work on nano-array structured catalysts, restrictions on the industrial development and application of high-performance catalysts, and uneven distribution of catalyst active components, so as to achieve good electron transport performance, meeting environmental protection and sustainable development, and the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a. Divide 8cm 2 The foamed nickel substrate was ultrasonically cleaned with hydrochloric acid for 5 minutes, then ultrasonically cleaned with absolute ethanol for 5 minutes, and then cleaned with deionized water to obtain a foamed nickel substrate for subsequent use;

[0027] b. Dissolve 0.5820g of cobalt nitrate hexahydrate, 0.2963g of ammonium fluoride and 0.6000g of urea in 40mL of deionized water, stir evenly, and put it into a hydrothermal kettle;

[0028] c. Immerse the foamed nickel substrate obtained in step a into the mixed solution obtained in step b, and heat it in a reactor at 120° C. for 12 hours, and cool it to room temperature naturally after the reaction; the obtained substrate is washed with water and absolute ethanol to remove impurities. Dry in an oven at ℃ for 2 hours;

[0029] d. Soluble cobalt salt and urea are dissolved in deionized water to form a solution, wherein the concentration of cobalt ions is 0.025mol / L, the addition is 0.296g, and the sub...

Embodiment 2

[0036] a. Divide 8cm 2 The foamed nickel substrate was ultrasonically cleaned with hydrochloric acid (1mol / L) for 5 minutes, then ultrasonically cleaned with absolute ethanol for 5 minutes, and then cleaned with deionized water to obtain an iron substrate for subsequent use;

[0037] b. Dissolve 1.164g of cobalt nitrate hexahydrate and 0.56g of hexamethylenetetramine in 40mL of deionized water, stir evenly, and put it into a hydrothermal kettle;

[0038] c. Immerse the foamed nickel substrate obtained in step a into the mixed solution obtained in step b, and heat it with water at 100°C for 10 hours in a reaction kettle, and cool it to room temperature naturally after the reaction; the obtained substrate is washed with water and absolute ethanol to remove impurities. Dry in an oven at ℃ for 2 hours;

[0039] d. The substrate obtained in step c is deposited and precipitated using NaBH 4 In situ reduction of 200 μL chloroauric acid to obtain Au / Co(Oh) 2 Nanoarray Structured Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com