Composite coating on surface of magnesium alloy structural component and preparation method of composite coating

A surface composite, magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems such as the large difference in the mechanical properties of the ceramic reinforcement layer, the inability to meet the requirements of wear and corrosion resistance, and the adhesion of cracks. The effect of small deformation and excessively uniform interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

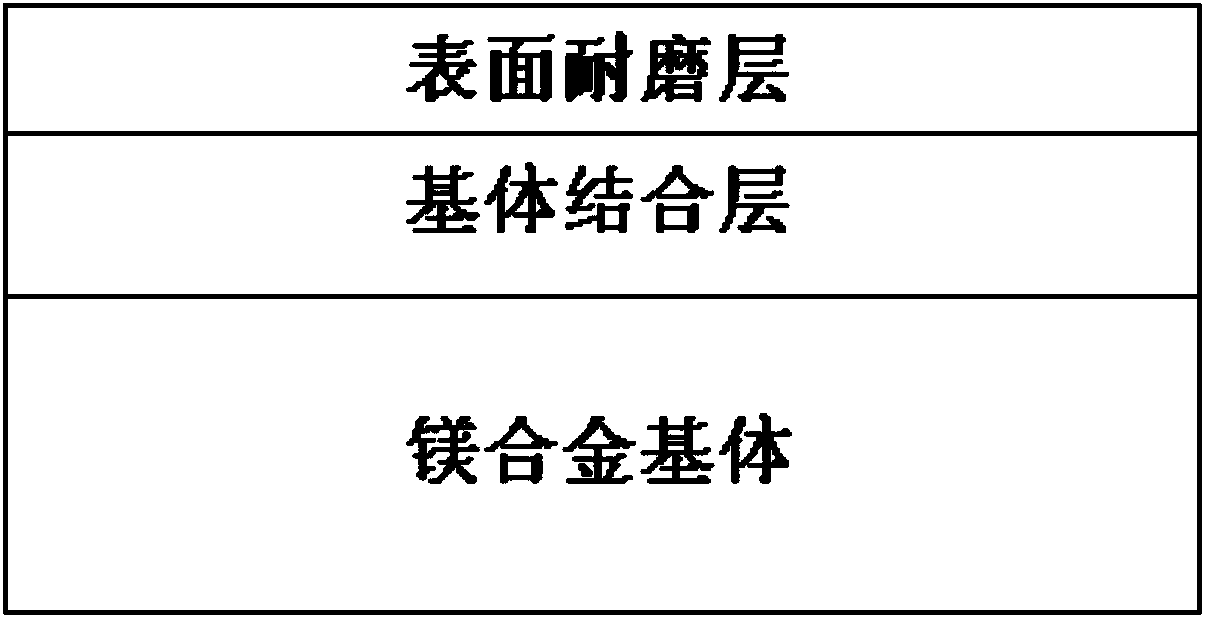

Image

Examples

Embodiment 1

[0026] The method for preparing a composite coating on the surface of a magnesium alloy structure in this embodiment comprises the following steps:

[0027] 1) Magnesium alloy pretreatment: Sandblasting the surface of magnesium alloy profiles obtained by 3D printing to remove surface rust and oxides and improve surface roughness to enhance the bonding strength between the surface and the coating;

[0028] The magnesium alloy used in this embodiment is a Mg-Al magnesium alloy, and its main components are magnesium and aluminum;

[0029] 2) Cleaning and drying: cleaning the magnesium alloy in step 1) with an organic solvent and air-drying naturally;

[0030] 3) Ion implantation: Plasma immersion ion implantation (PIII) is used to implant oxygen ions into the magnesium alloy in step 2) to form a firm matrix bonding layer (the bonding layer is mainly composed of MgO and Al 2 o 3 ceramics),

[0031] In this embodiment, the oxygen ion implantation energy is 40-50Kev, and the impl...

Embodiment 2

[0037] The method for preparing a composite coating on the surface of a magnesium alloy structure in this embodiment comprises the following steps:

[0038] 1) Magnesium alloy pretreatment: Sandblasting the surface of magnesium alloy profiles obtained by 3D printing to remove surface rust and oxides and improve surface roughness to enhance the bonding strength between the surface and the coating;

[0039] The magnesium alloy used in this embodiment is a Mg-Al magnesium alloy, and its main components are magnesium and aluminum;

[0040] 2) Cleaning and drying: cleaning the magnesium alloy in step 1) with an organic solvent and air-drying naturally;

[0041] 3) Ion implantation: Plasma immersion ion implantation (PIII) is used to implant oxygen ions into the magnesium alloy in step 2) to form a firm matrix bonding layer (the bonding layer is mainly composed of MgO and Al 2 o 3 ceramics),

[0042] In this embodiment, the oxygen ion implantation energy is 40-50Kev, and the impl...

Embodiment 3

[0048]The method for preparing a composite coating on the surface of a magnesium alloy structure in this embodiment comprises the following steps:

[0049] 1) Magnesium alloy pretreatment: Sandblasting the surface of magnesium alloy profiles obtained by 3D printing to remove surface rust and oxides and improve surface roughness to enhance the bonding strength between the surface and the coating;

[0050] The magnesium alloy used in this embodiment is a Mg-Al magnesium alloy, and its main components are magnesium and aluminum;

[0051] 2) Cleaning and drying: cleaning the magnesium alloy in step 1) with an organic solvent and air-drying naturally;

[0052] 3) Ion implantation: Plasma immersion ion implantation (PIII) is used to implant oxygen ions into the magnesium alloy in step 2) to form a firm matrix bonding layer (the bonding layer is mainly composed of MgO and Al 2 o 3 ceramics),

[0053] In this embodiment, the oxygen ion implantation energy is 40-50Kev, and the impla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com