Device for recovering sodium chloride and glycerinum from high-salinity and high-depth organic wastewater containing glycerinum

A technology of organic waste water and recycling device, applied in the directions of alkali metal chlorides, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of waste of resources, pollute the environment, and have not been recycled, and achieve guaranteed feasibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

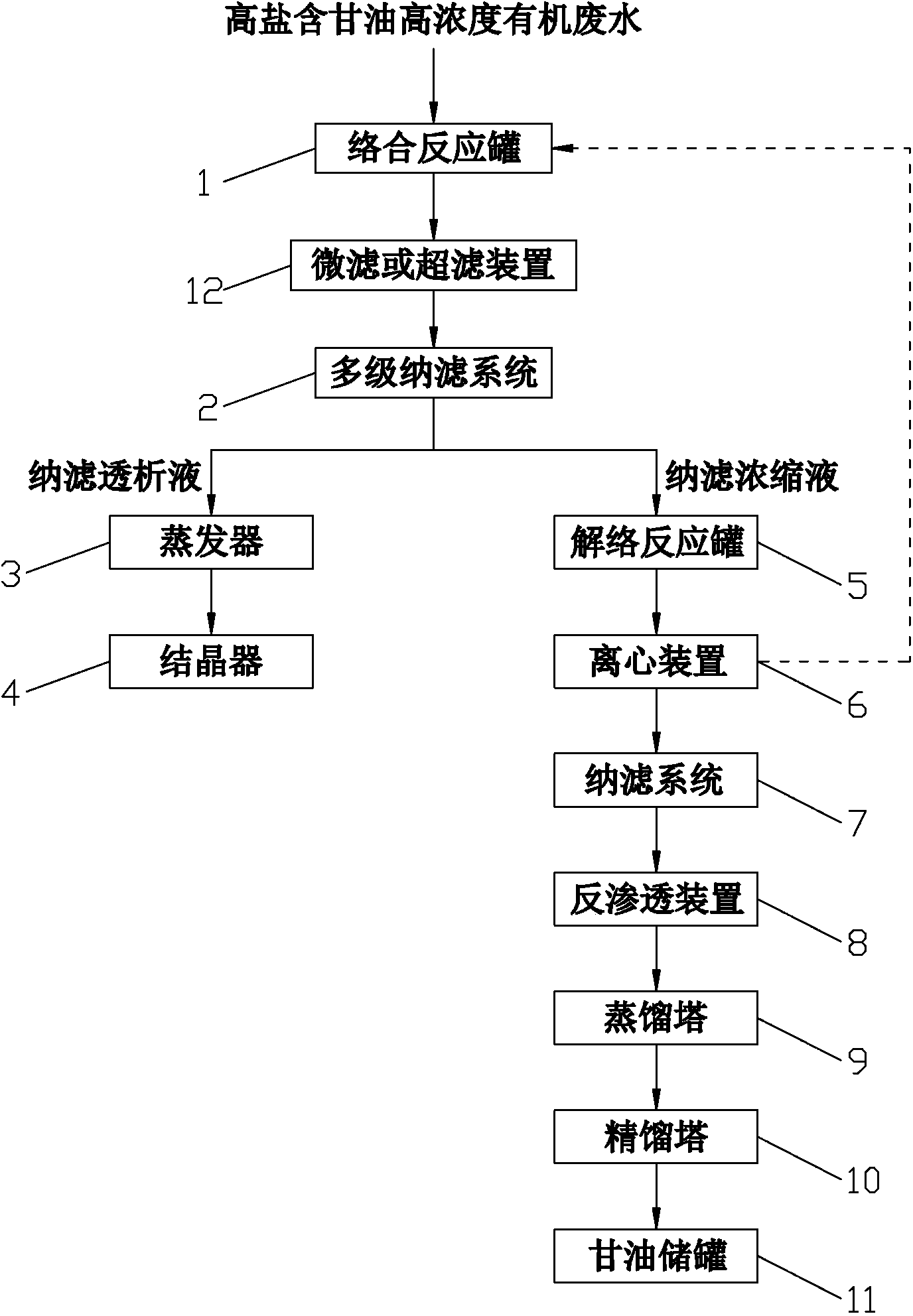

[0032] (1) Complexation

[0033] The high-salt glycerin-containing waste water is collected by the pipeline and discharged into the complexation reaction tank 1, and the alkali solution and copper sulfate are added in the complexation reaction tank 1, so that the glycerol contained in the waste water undergoes a complexation reaction with copper ions under alkaline conditions, Produce copper glycerol.

[0034] The concentration of sodium chloride in the high-salt glycerin-containing wastewater is 30%, the concentration of glycerin is 2%, and the alkali solution is sodium hydroxide solution.

[0035] (2) Nanofiltration desalination (separation of glycerol and salt)

[0036]The effluent from the complexation reaction tank 1 in step (1) enters the multi-stage nanofiltration system 2 for graded filtration and desalination to obtain a nanofiltration concentrate containing copper glycerol and a nanofiltration dialysate containing sodium chloride. In order to ensure that the multi-...

Embodiment 2

[0059] (1) Complexation

[0060] The high-salt glycerin-containing wastewater is collected through the pipeline and then discharged into the complexation reaction tank 1. Alkaline solution and other metal salts are added to the complexation reaction tank 1 to make the glycerin contained in the wastewater complex with other metal ions under alkaline conditions. reaction to generate other glycerol metal complexes.

[0061] The concentration of sodium chloride in the high-salt glycerin-containing wastewater is 18%, the concentration of glycerin is 20%, the alkaline solution is sodium carbonate solution, other metal salts are zinc oxide, other metal ions are zinc ions, and other glycerol metal complexes The substance is zinc glycerol.

[0062] (2) Nanofiltration desalination (separation of glycerol and salt)

[0063] The effluent from the complexation reaction tank 1 in step (1) enters the multi-stage nanofiltration system 2 for graded filtration and desalination to obtain a nan...

Embodiment 3

[0085] (1) Complexation

[0086] The high-salt glycerin-containing wastewater is collected through the pipeline and then discharged into the complexation reaction tank 1. Alkaline solution and other metal salts are added to the complexation reaction tank 1 to make the glycerin contained in the wastewater complex with other metal ions under alkaline conditions. reaction to generate other glycerol metal complexes.

[0087] The concentration of sodium chloride in the high-salt glycerol-containing wastewater is 30%, the concentration of glycerol is 12%, the alkali solution is sodium carbonate solution, other metal salts are ferric chloride, other metal ions are iron ions, and other glycerol metal complexes The compound is iron glycerol.

[0088] (2) Nanofiltration desalination (separation of glycerol and salt)

[0089] The water effluent from the complexation reaction tank 1 in step (1) enters the multi-stage nanofiltration system 2 for graded filtration and desalination to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com