Coal chemical industry wastewater zero emission technology and special equipment thereof

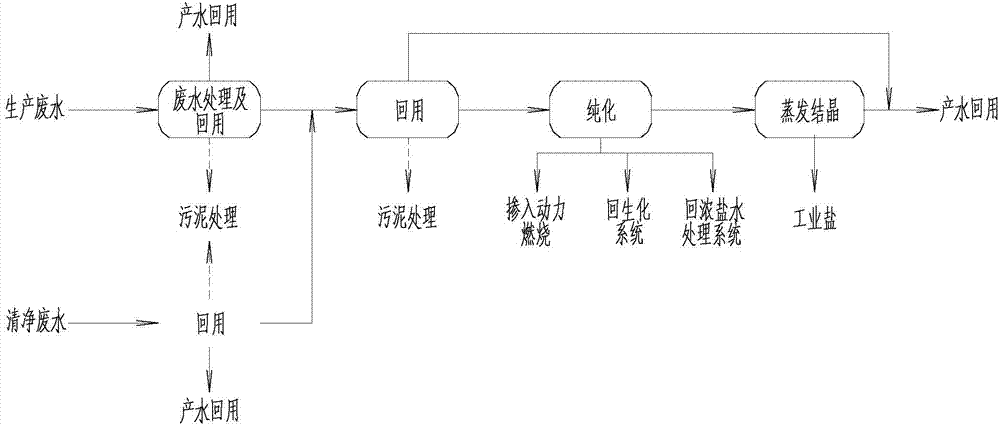

A technology for coal chemical wastewater and special equipment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of polluted environment, low recovery rate of wastewater, low recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

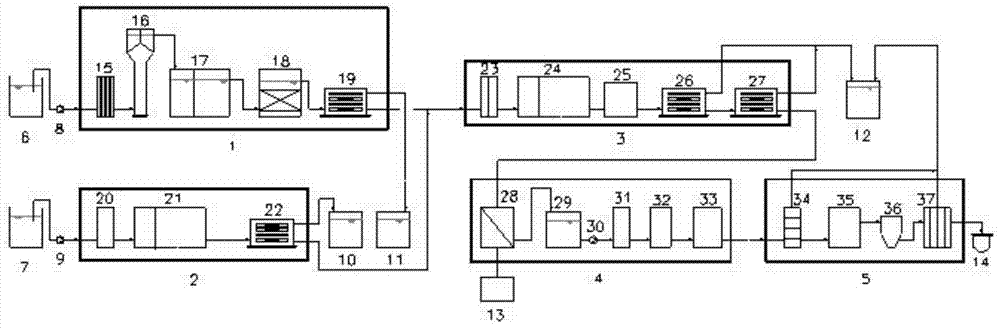

[0025] as attached figure 2 As shown, a special equipment for coal chemical wastewater zero discharge process, which includes wastewater treatment and reuse system A equipment 1, reuse system B equipment 2, reuse system C equipment 3, purification system D equipment 4, evaporation and crystallization equipment 5. The first raw water pool 6, the second raw water pool 7, the first water inlet pump 8, the second water inlet pump 9, the first water production pool 10, the second water production pool 11, the third water production pool 12, the thick liquid collection pool 13, Industrial salt recovery bag 14, third water inlet pump 30;

[0026] The first raw water pool 6 is connected to the waste water treatment and reuse system A equipment 1, the connecting pipeline is equipped with a first water inlet pump 8, and the clear liquid output end of the waste water treatment and reuse system A equipment 1 is connected to the second water production pool 11 , the concentrated liquid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com