Organic montmorillonite (OMMT) and method for modifying polypropylene resin by using same

A technology of organic montmorillonite and sodium-based montmorillonite, applied in the field of organic montmorillonite and its modified polypropylene resin, can solve problems such as unfavorable dispersion, and achieve the advantages of improving affinity, increasing tensile strength and increasing crystallization temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] Preparation method of organic montmorillonite: 1) Add sodium-based montmorillonite into distilled water, stir and heat to 80 degrees, add cetyltrimethylammonium bromide aqueous solution dropwise, stop heating after 4 hours to wash away residual halide ions , Vacuum drying to constant weight, crushing and sieving to obtain modified organic montmorillonite CMMT; 2) adding the organic montmorillonite CMMT prepared in step 1) and epoxy resin in a mass ratio of 19:1 into a mortar, Grind under infrared for 1 hour, dry at 160°C for 3 hours, vacuum dry and sieve to obtain the secondary modified organic montmorillonite EMMT; 3) The secondary modified organic montmorillonite EMMT prepared in step 2) Add phorone diisocyanate to a mortar at a mass ratio of 17:1, grind under infrared for 1 hour, dry at 75 degrees for 3 hours, vacuum dry and sieve to obtain the third modified organic montmorillonite IMMT; 4) Step 3) The prepared tertiary modified organic montmorillonite IMMT and octad...

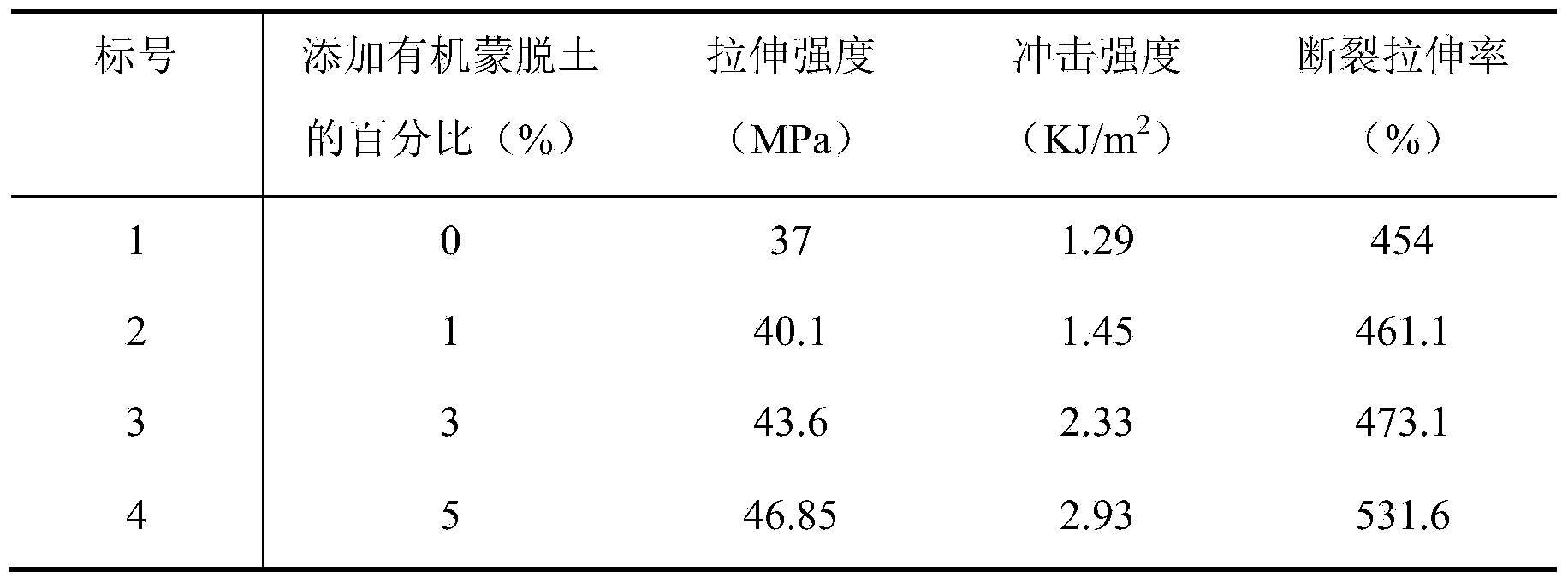

Embodiment 1

[0015] The weight percentages of each component are: 0.1% fixed antioxidant, 0.5% lubricant, organic montmorillonite OMMT 0, and polypropylene 99.4%; the materials in the above weight percentages are added to the high-speed mixer and mixed evenly; the mixed materials enter the extrusion Machine, a 180 degree twin-screw extruder melted and pelletized to obtain unmodified polypropylene resin masterbatch 1.

Embodiment 2

[0017] The weight percentages of each component are: 0.1% of fixed antioxidant, 0.5% of lubricant, 1% of organic montmorillonite OMMT, and 99.4% of polypropylene; the materials in the above weight percentage are added to the high-speed mixer and mixed evenly; the mixed materials enter the extrusion Out of the machine, a 180-degree twin-screw extruder melted and pelletized to obtain a modified polypropylene resin masterbatch 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com