PVC (polyvinyl chloride) processing aid and preparation method thereof

A technology of processing aids and initiators, applied in the field of PVC processing aids and their preparation, can solve the problems of rising ACR processing costs, unsuccessful application, poor thermal stability, etc., and achieves improved melt strength and surface finish, low price , Improve the effect of poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

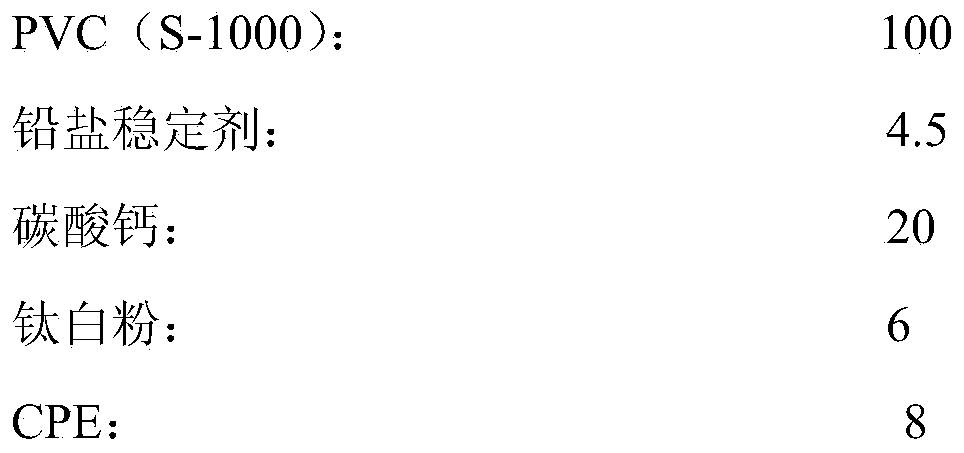

Embodiment 1

[0034] The preparation method of described PVC processing aid, comprises the following steps:

[0035] (1) Add 300g deionized water, 0.5g diameter expander (trisodium phosphate), 2g emulsifier (sodium lauryl sulfate), 100g core layer comonomer (vinyl acetate and methyl acrylate) into the reactor Mixed at a mass ratio of 60:40), 0.2g initiator (potassium persulfate), heated to 65°C, and reacted for 4 hours under nitrogen protection to obtain a nuclear layer emulsion;

[0036] (2) in the core layer emulsion that step (1) obtains, add 2g emulsifier (sodium lauryl sulfate), 100g shell layer comonomer (styrene and acrylonitrile are mixed in 80:20 by mass ratio), Control the temperature at 65°C, add 0.3g initiator (potassium persulfate), and react under nitrogen protection for 4 hours. The reaction is divided into 5 stages. After the reaction is completed, the temperature is raised to 85°C, matured for 1 hour, filtered, and dried to obtain the product.

Embodiment 2

[0038] The preparation method of described PVC processing aid, comprises the following steps:

[0039] (1) Add 300g deionized water, 0.8g diameter expander (sodium sulfate), 3g emulsifier (sodium dodecylbenzenesulfonate), 100g core layer comonomer (vinyl acetate and methyl acrylate) to the reactor Esters are mixed at a mass ratio of 80:20), 0.1g initiator (ammonium persulfate), heated to 60°C, and reacted for 3 hours under nitrogen protection to obtain a nuclear layer emulsion;

[0040] (2) In the core layer emulsion obtained in step (1), add 3g emulsifier (sodium dodecylbenzenesulfonate), 160g shell layer comonomer (styrene and acrylonitrile are mixed in a mass ratio of 75:25 ), control the temperature at 75°C, add 0.5g initiator (AIBN), and react under nitrogen protection for 3 hours. The reaction is divided into 4 stages. After the reaction is completed, the temperature is raised to 80°C, matured for 1 hour, filtered, and dried to obtain the product.

Embodiment 3

[0042] The preparation method of described PVC processing aid, comprises the following steps:

[0043] (1) Add 200g deionized water, 0.2g diameter expander (sodium chloride), 1g emulsifier (sodium dodecylbenzenesulfonate), 100g core layer comonomer (vinyl acetate and acrylic acid) to the reactor Methyl ester is mixed at a mass ratio of 75:25), 0.1g initiator (potassium persulfate and sodium bisulfite are mixed at a mass ratio of 1:1), the temperature is raised to 40°C, and the reaction is carried out under nitrogen protection for 4 hours to obtain a core layer emulsion ;

[0044] (2) In the core layer emulsion obtained in step (1), add 1g emulsifier (sodium dodecylbenzenesulfonate), 80g shell layer comonomer (styrene and acrylonitrile are mixed in a mass ratio of 70:30 ), control the temperature at 65°C, add 0.1g initiator (potassium persulfate), and react for 5 hours under the protection of nitrogen. .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap