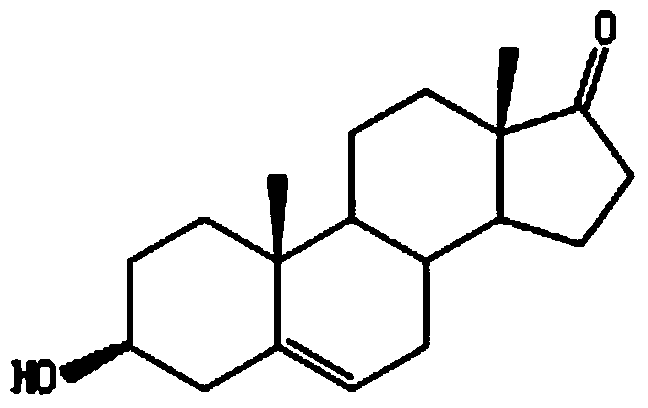

Method for producing dehydroepiandrosterone through microbial fermentation

A technology for dehydroepiandrosterone and microbial fermentation, applied in the direction of microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problems of high toxicity of organic solvents, expensive raw materials, cumbersome preparation steps, etc., and achieve improved product quality The effect of quality yield, reduction of production cost and simplification of extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] 2.1 Preparation of Competent Cells

[0041] will concentration 10 7 -10 9 Individuals / ml of Mycobacterium smegmatis was inoculated in LB liquid medium with 10% inoculum size, containing 0.05% Tween 80 by weight percentage in the LB liquid medium, and cultivated to OD at 30°C 600 =0.4-0.5, add glycine with a final concentration of 1% to continue culturing, when OD 600 When it reaches 0.8-1.0, start to prepare competent state;

[0042] First, the bacterial suspension was centrifuged at 11000g at 4°C for 20 min, and the supernatant was discarded; then, the bacteria were resuspended in a glycerol Tween solution containing 0.05% Tween 80 by weight in an amount of 1 / 6 of the medium volume, The mass percentage of the glycerin solution is 10%, centrifuged at 4000g, 4°C for 10min, discard the supernatant after the centrifugation is completed; wash the bacteria twice again with the above method, and the volume of the glycerol Tween solution used is 1 / 15 of the medium volume re...

Embodiment 1

[0046] Propagate ZS3-△MSMEG_5228 in the seed medium first, and wait until the seed medium OD 600 When ≈15, insert it with 30% inoculum in the fermenter that fermentation medium and phytosterol are housed and carry out fermentation transformation, and the weight percent of phytosterol and fermentation medium is 1%, and the condition of fermentation transformation is: temperature 29-31°C, tank pressure 0.05MPa, stirring speed 150-200rpm, culture period 4-5day;

[0047] The components of the seed medium are: glucose 15g / L, K 2 HPO 4 0.3g / L, MgSO 4 ·7H 2 O0.8g / L, (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O0.02g / L, CaCO 3 5.5g / L and citric acid 1.0g / L, the pH of the seed medium is 6.0;

[0048] The components of the fermentation medium are: glucose 15g / L, peptone 30g / L, bean cake powder 25g / L, K 2 HPO 4 0.5g / L, MgSO 4 ·7H 2 O1.0g / L, (NH 4 ) 2 Fe(SO 4 )2·6H 2 O0.06g / L, CaCO 3 4.5g / L, citric acid 3.0g / L and NH 4 NO 3 1.5g / L, the pH of the fermentation medium is 6.0.

[0049] ...

Embodiment 2

[0052] Change the inoculum amount in Example 1 to 40%, and the rest of the conditions remain unchanged.

[0053] The test result is: the final yield of DHEA is 88.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com