Method for producing makkolli treated under ultra high pressure and makkolli produced by using the same

A technology for makgeolli and a manufacturing method, which is applied in the preparation of alcoholic beverages, microorganism-based methods, biochemical equipment and methods, etc., can solve problems such as poor functionality, low functionality such as taste, and increased number of microorganisms, To achieve the effect of extending the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 300 g of koji to 1,000 g of hard rice made of rice and mix, then add 1,300 g of raw water, and ferment at 25°C. At the 96th hour, the fermented product is filled into a polypropylene bottle and sealed, and then placed in a 25°C At a temperature of 250 MPa, an ultrahigh pressure machine (Quintus food processor, QFP 6, ABB Autoclave systems Inc., Columbus, Ohio, USA) was used for 5 minutes to perform the first ultrahigh pressure treatment. Fermentation was further carried out for 48 hours after the first ultra-high pressure treatment, and the second ultra-high pressure treatment was performed at a temperature of 25° C. under a pressure of 400 MPa for 5 minutes with an ultra-high pressure machine to produce makgeolli wine.

Embodiment 2

[0043] Carried out in the same manner as in Example 1 above, however, during the first ultra-high pressure treatment, at a temperature of 25° C., the ultra-high pressure treatment was carried out at a pressure of 150 MPa for 3 minutes, and then further performed at the same temperature at a pressure of 250 MPa. 2 minutes of ultra-high pressure treatment, thus making makkolli wine.

experiment example 1

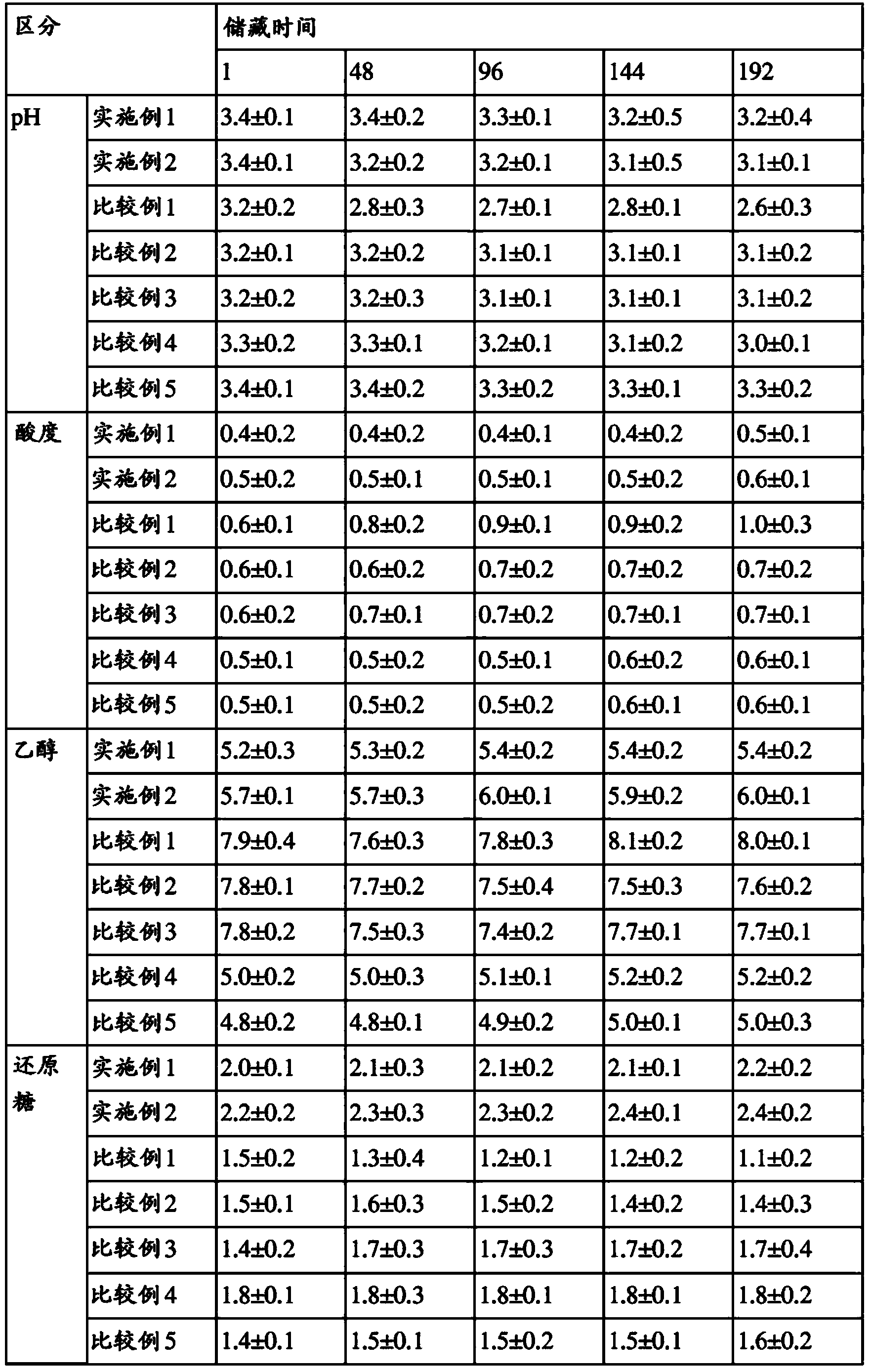

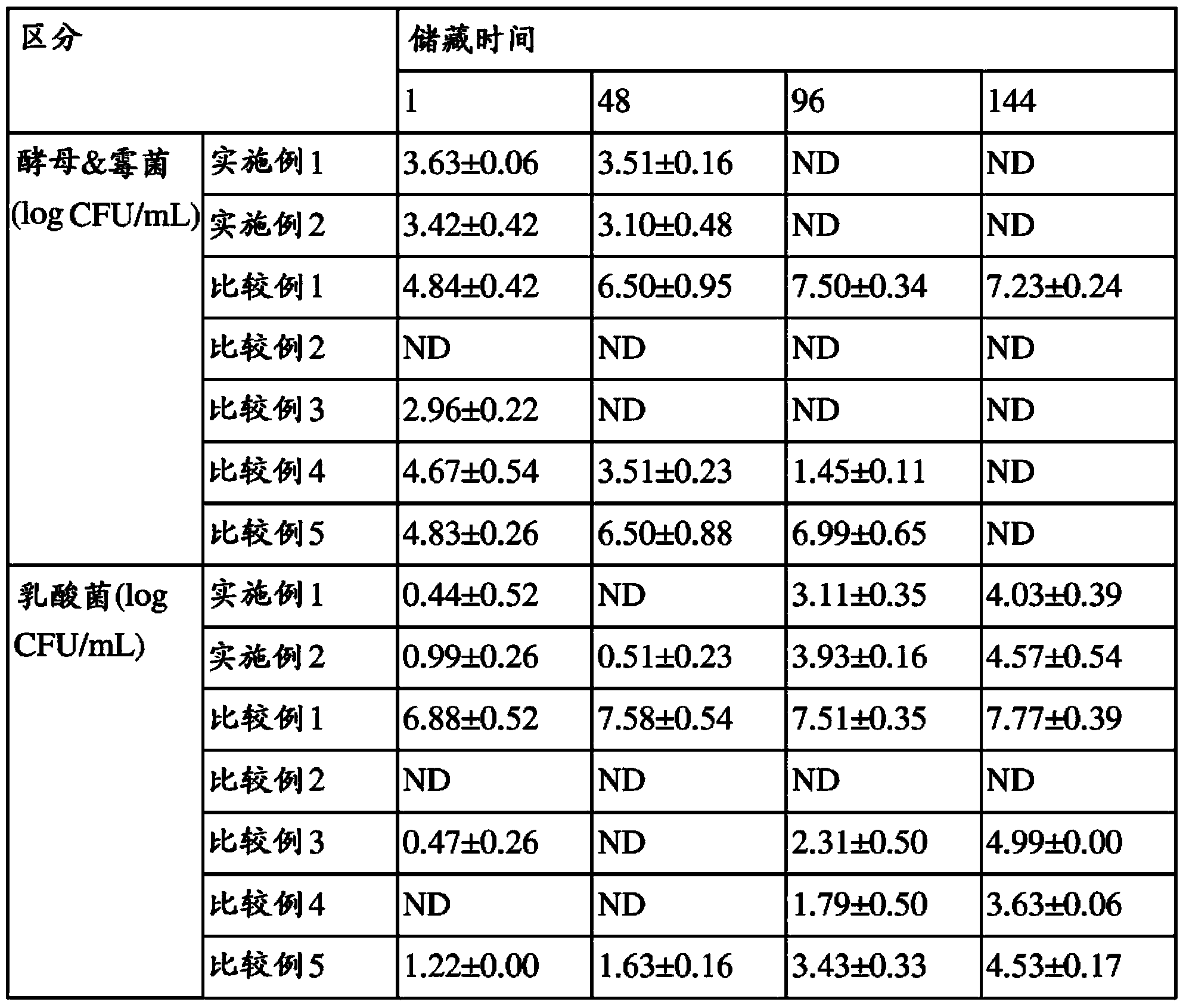

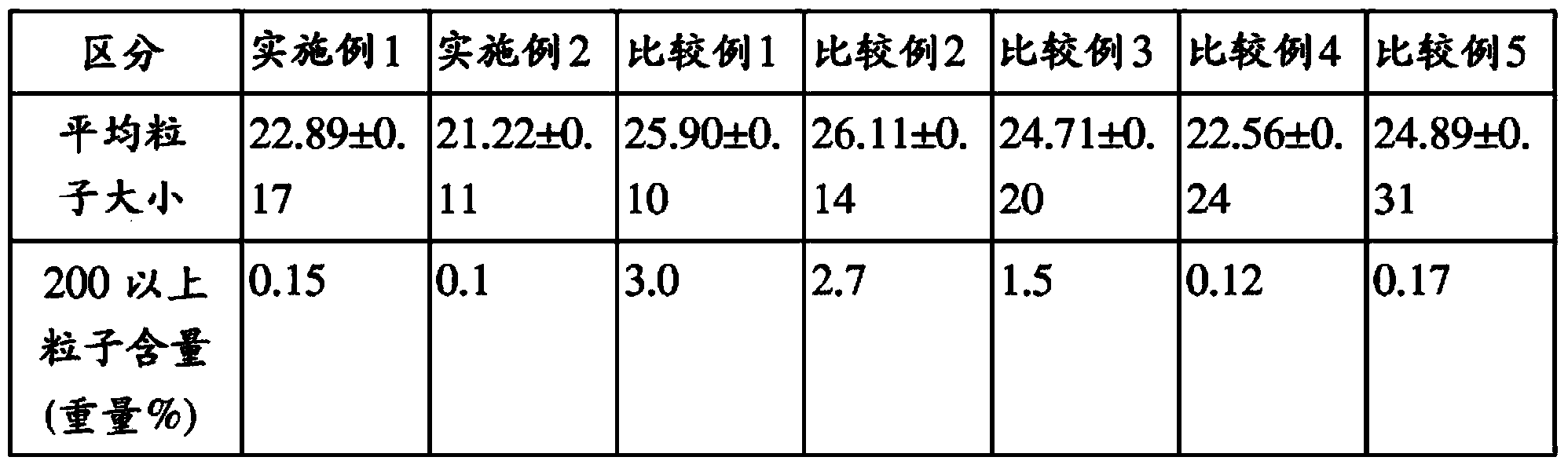

[0054] Experimental example 1. Determination of pH, acidity, ethanol, reducing sugar

[0055] The pH, acidity, ethanol and reducing sugar were measured using the makgeolli produced in Examples and Experimental Examples, and the results are shown in Table 1 below.

[0056] 1-1. pH: Measured with a pH meter (Orion 2-star Benchtop, Thermo scientific, USA).

[0057] 1-2. Acidity (%): Add 1% (v / v) phenolphthalein (phenolphthalein) to the Makgeolli as an indicator, add 0.1N NaOH solution drop by drop until the color of the Makkolli turns bright red, Then, this was converted into lactic acid content (%) and calculated.

[0058] 1-3. Ethanol (%): After distilling 100ml of Makgeolli wine using a distillation device (Wise Therm WHM, DAIHAN, Korea), measure the degree (%) of ethanol with an alcohol meter, according to Gay-Lussac (Gay -Lussac) alcohol content conversion table for temperature correction.

[0059] 1-4. Reducing sugar (%): add 0.5g of dinitrosalicylic acid (dinitrosalicyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com