A kind of carbon dioxide adsorbent and preparation method thereof

A carbon dioxide and adsorbent technology, which is applied in the field of carbon dioxide adsorbent and its preparation, can solve the problems of easily clogged mesopores and decreased adsorption capacity, and achieve the effects of large absorption capacity, improved adsorption capacity, and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

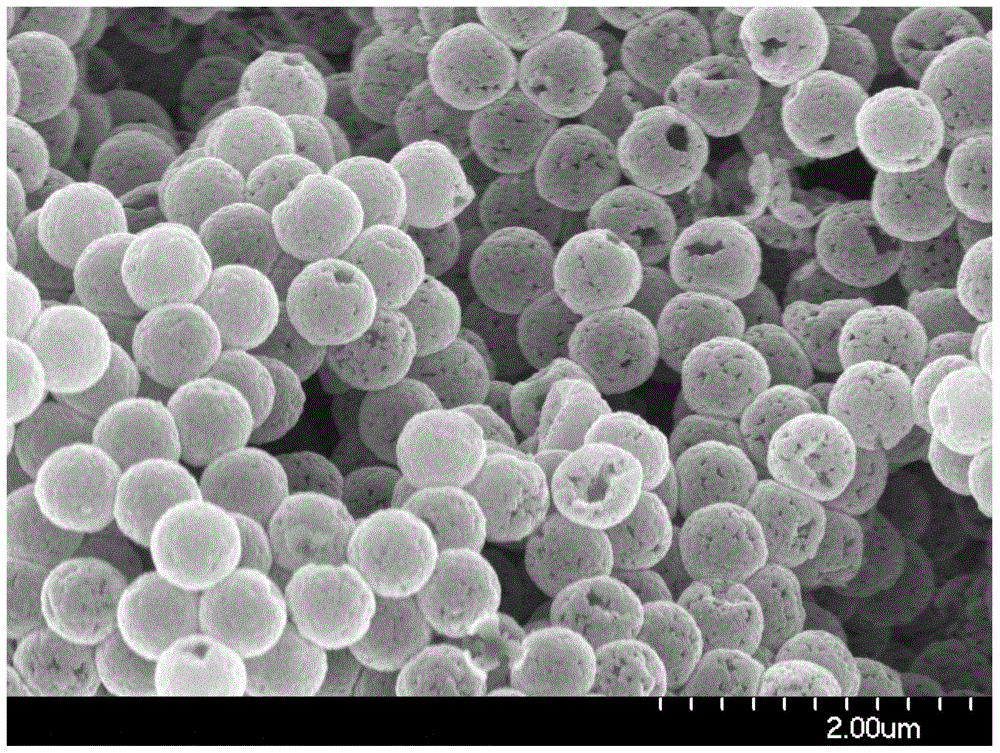

[0040] (1) Preparation of silica hollow sphere carrier: Add 550 mg of tetraethyl orthosilicate and 6.96 ml of polystyrene emulsion suspension (diameter 526 nm, 2.62 wt %) into a 10 ml glass bottle, and the resulting mixture is continuously ultrasonicated for 2 hours , centrifuged at 7000rmp for 40min, dried at room temperature for 12h, and then the polystyrene emulsion template was calcined at 600°C for 8 hours to remove it. The as-prepared silica hollow spheres are denoted as SH.

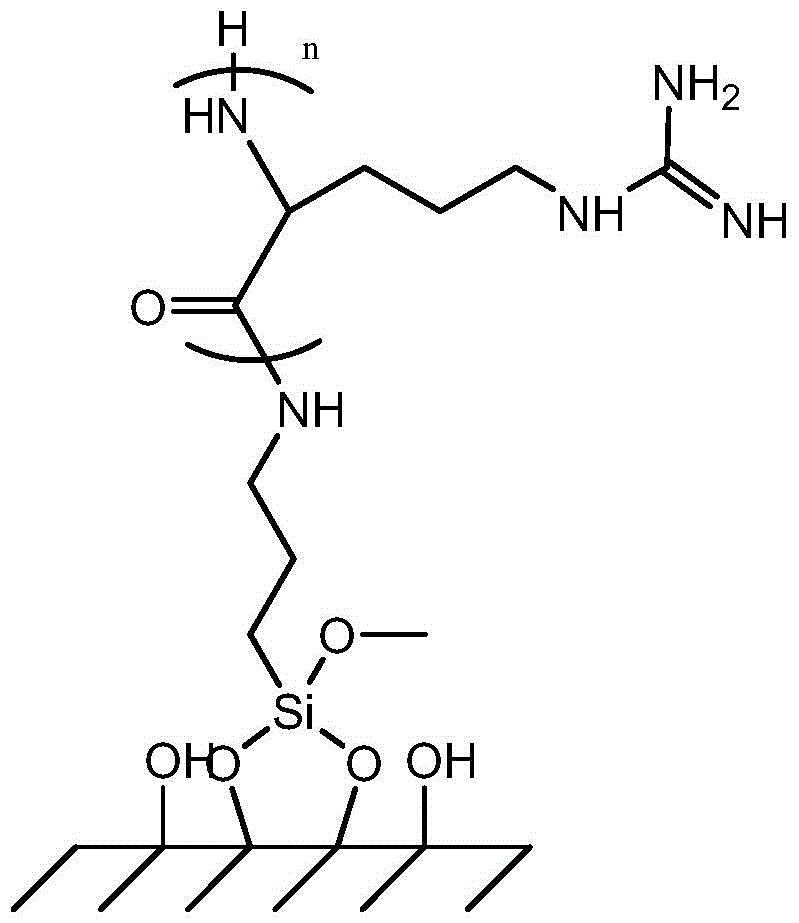

[0041](2) Take 0.5g of silica hollow sphere carrier, heat and dry under vacuum at 100°C for 12h, then add 30ml of anhydrous toluene and 3-aminopropyltrimethoxysilane (0.398mmol), and stir the mixture at room temperature for 24h Hour. The resulting solid product was washed successively with toluene, methanol, methanol / water (1:1) and methanol, and dried under vacuum.

[0042] (3) Under the protection of nitrogen, add 13.2 g of benzyloxycarbonyl arginine and 50 ml of tetrahydrofuran (THF) to the th...

Embodiment 2

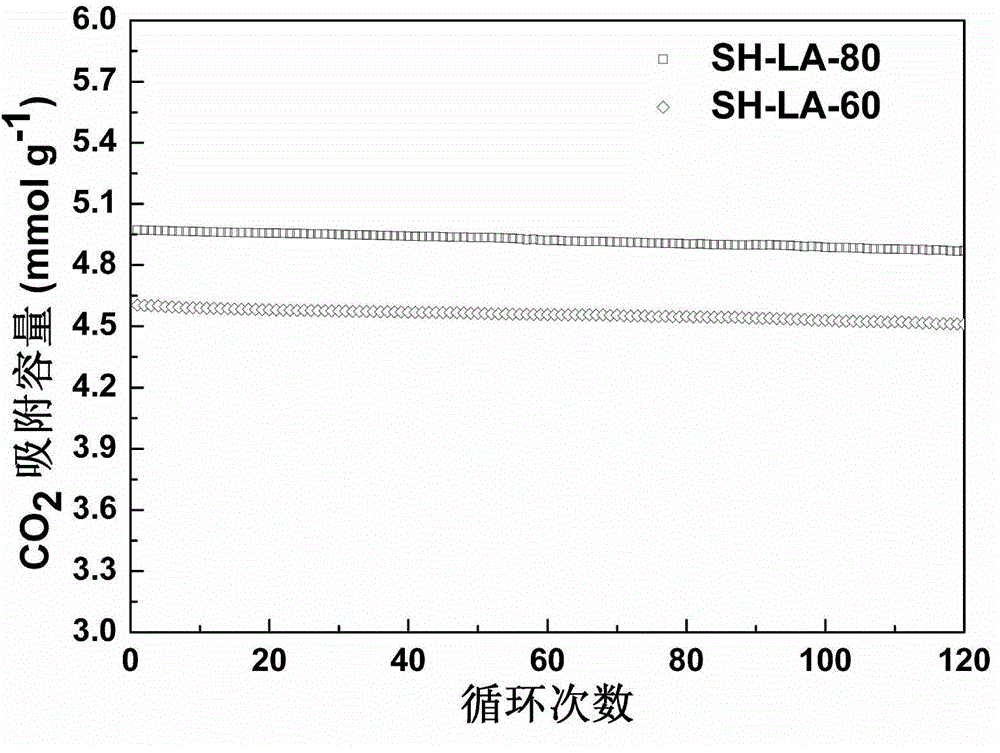

[0044] A carbon dioxide adsorbent, the inner and outer surfaces of which are aminated silicon dioxide hollow spheres as a carrier, linear poly-L-arginine (PLA) is fixed on the inner and outer surfaces of the carrier through chemical bonds in the form of in-situ polymerization.

[0045] A method for preparing a carbon dioxide adsorbent, using an amination agent to aminate the inner and outer surfaces of silica hollow spheres, and then polymerizing PLA on the inner and outer surfaces of the hollow spheres by in-situ polymerization to obtain the carbon dioxide adsorbent;

[0046] The amination reagent is selected from the group consisting of 3-aminopropyltrimethoxysilane;

[0047] The pore diameter of the silica hollow spheres is 50nm;

[0048] The PLA is a linear polymer;

[0049] Specific steps are as follows:

[0050] 1) Preparation of silica hollow sphere carrier: Add tetraethyl orthosilicate and polystyrene emulsion suspension into a glass bottle, and the resulting mixture...

Embodiment 3

[0061] (1) Preparation of silica hollow sphere carrier: Add 660 mg of tetraethyl orthosilicate and 8.35 ml of polystyrene emulsion suspension (diameter 526 nm, 2.62 wt %) into a 10 ml glass bottle, and the resulting mixture is continuously ultrasonicated for 2 hours , centrifuged at 7000rmp for 40min, dried overnight at room temperature, and then calcined the polystyrene emulsion template at 600°C for 6 hours to remove it.

[0062] (2) Take 0.6g of silica hollow sphere carrier, heat and dry under vacuum overnight at 100°C, then add 36ml of anhydrous toluene and 3-aminopropyltrimethoxysilane (0.478mmol), and place the mixture at room temperature Stir for 24 hours. The resulting solid product was washed successively with toluene, methanol, methanol / water (1:1) and methanol, and dried under vacuum.

[0063] (3) Under the protection of nitrogen, add 13.2 g of benzyloxycarbonyl arginine and 50 ml of tetrahydrofuran (THF) to the three-necked flask, keep stirring, and ice bath; add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com