Polyethyleneimine modified chitosan microsphere medium as well as preparation and application methods thereof

A technology of polyethyleneimine and chitosan microspheres, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc. Capacity reduction and other issues, to achieve the effect of low cost, simple process, easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]The preparation method of the aldylated CL-CS microsphere medium is as follows: take 1.5g of the chitosan microsphere medium CL-CS drained by the G3 funnel and place it in a 50mL Erlenmeyer flask, add 30mL of glutaraldehyde with a volume fraction of 10%. solution so that the concentration of the microsphere medium in the reaction system was 50 g / L, and reacted at 25° C. on a shaker at 50 rpm for 2 h. After the reaction, the microsphere medium was washed with deionized water and centrifuged repeatedly at a speed of 5000 rpm to remove glutaraldehyde that did not participate in the reaction, so as to prepare a completely aldylated CL-CS microsphere medium. According to the SEM analysis of the scanning electron microscope, it can be seen that the particle size range of the microsphere medium is 50-200 μm.

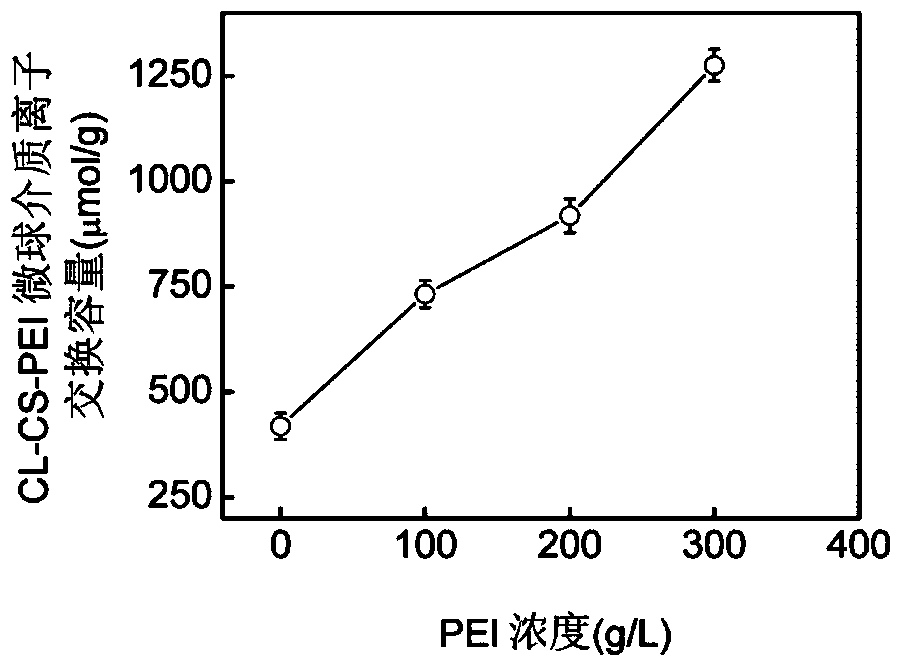

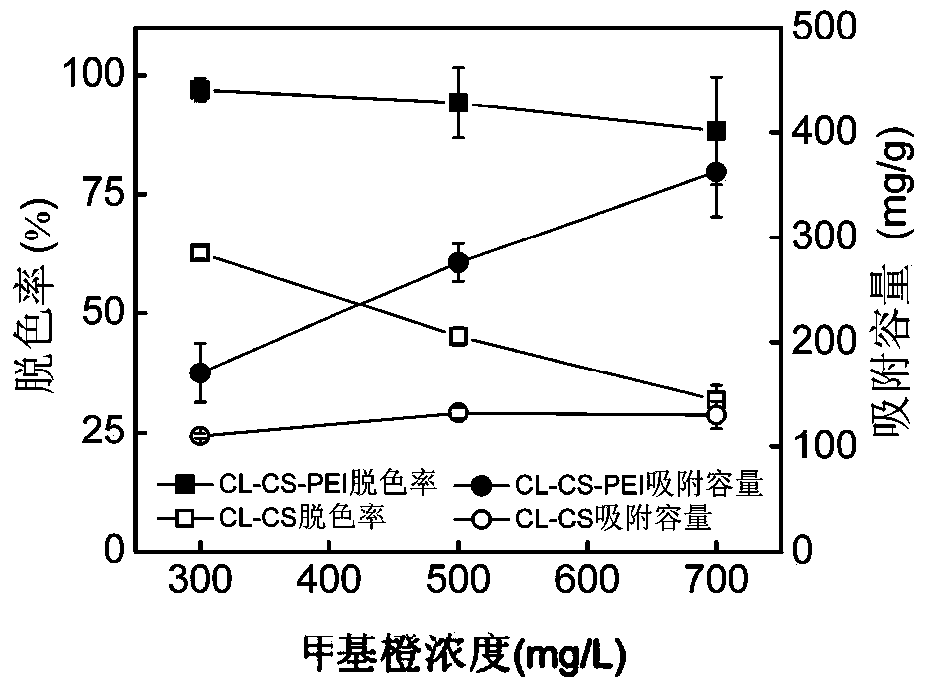

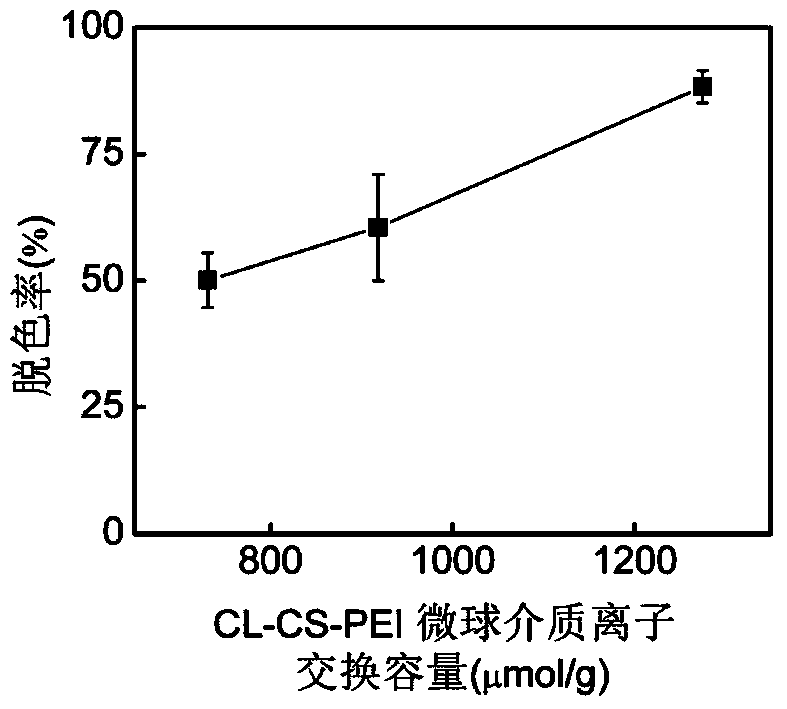

[0035] The preparation method of the CL-CS-PEI microsphere medium is as follows: 1 g of the above-mentioned aldehylated chitosan microsphere medium that was drained by th...

Embodiment 2

[0037] The preparation method of the aldylated CL-CS microsphere medium is as follows: take 1.8g of the chitosan microsphere medium CL-CS drained by the G3 funnel and place it in a 50mL Erlenmeyer flask, and add 30mL of glutaraldehyde with a volume fraction of 10%. solution so that the concentration of the microsphere medium in the reaction system is 60 g / L, and reacted at 30° C. on a shaker at 100 rpm for 4 hours. After the reaction, the microsphere medium was washed with deionized water and centrifuged repeatedly at a speed of 6000 rpm to remove glutaraldehyde that did not participate in the reaction, and a fully formylated CL-CS microsphere medium was prepared.

[0038] The preparation method of CL-CS-PEI microsphere medium is as follows: the 1.5g above-mentioned aldehydated chitosan microsphere medium that takes G3 funnel to drain is added in the NaOH solution of 20mL containing 200g / L PEI 1mol / L, make microsphere The concentration of the spherical medium in the reaction s...

Embodiment 3

[0040] The preparation method of the aldylated CL-CS microsphere medium is as follows: take 2.0 g of the chitosan microsphere medium CL-CS drained by the G3 funnel and place it in a 50 mL Erlenmeyer flask, and add 20 mL of glutaraldehyde with a volume fraction of 10%. Solution, so that the concentration of the microsphere medium in the reaction system is 100g / L, react at 40°C and 170rpm on a shaking table for 6h. After the reaction, the microsphere medium was washed with deionized water and centrifuged repeatedly at a rotational speed of 8000 rpm to remove glutaraldehyde that did not participate in the reaction, and a completely aldylated CL-CS microsphere medium was prepared.

[0041] The preparation method of CL-CS-PEI microsphere medium is as follows: the 1.5g above-mentioned aldehydated chitosan microsphere medium that the G3 funnel was drained was added to 15mL of 1mol / L NaOH solution containing 300g / L PEI, so that the microsphere The concentration of the spherical medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com