Method for preparing black titanium dioxide by using hydrothermal synthesis method

A black titanium dioxide, hydrothermal synthesis technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of unguaranteed product quality, high cost, harsh production conditions, etc., to achieve short reaction time and cost. Low cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

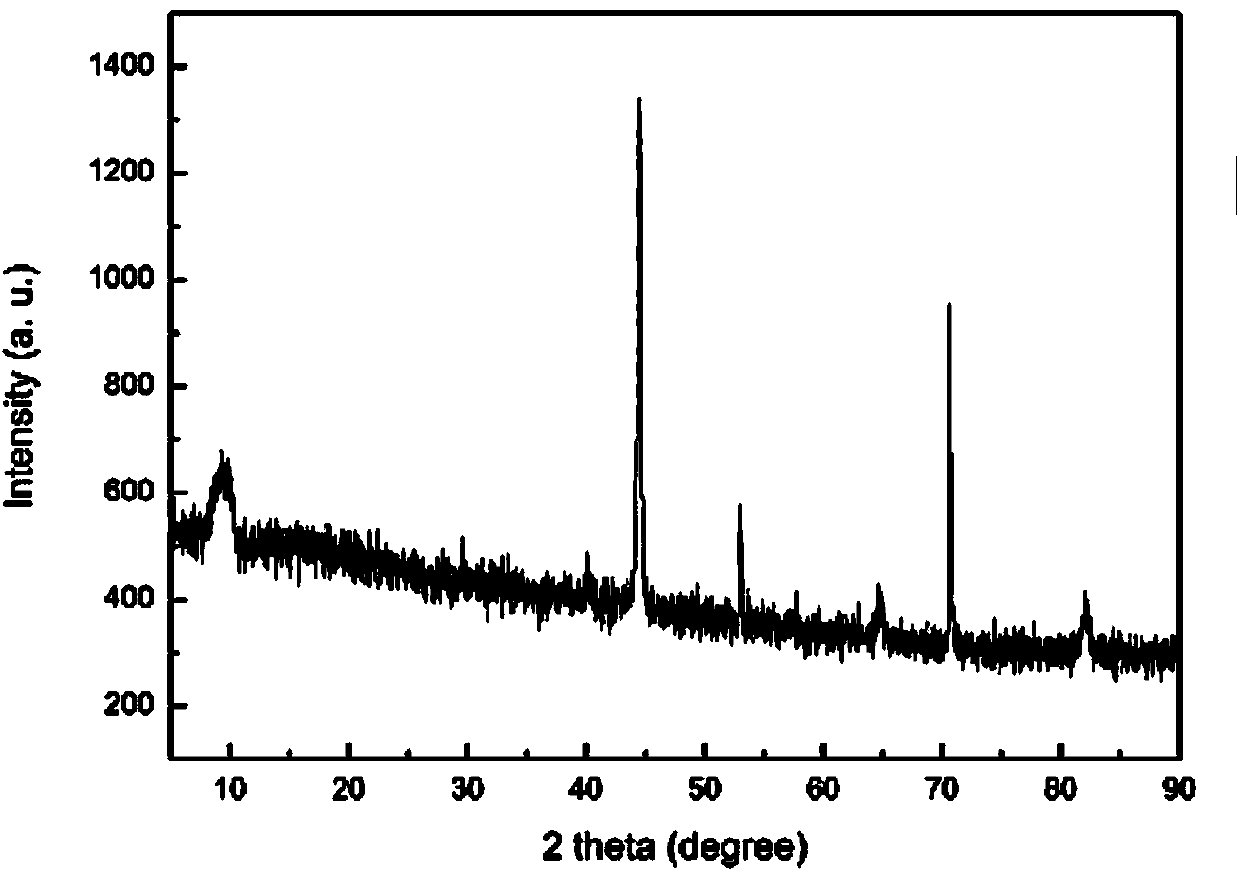

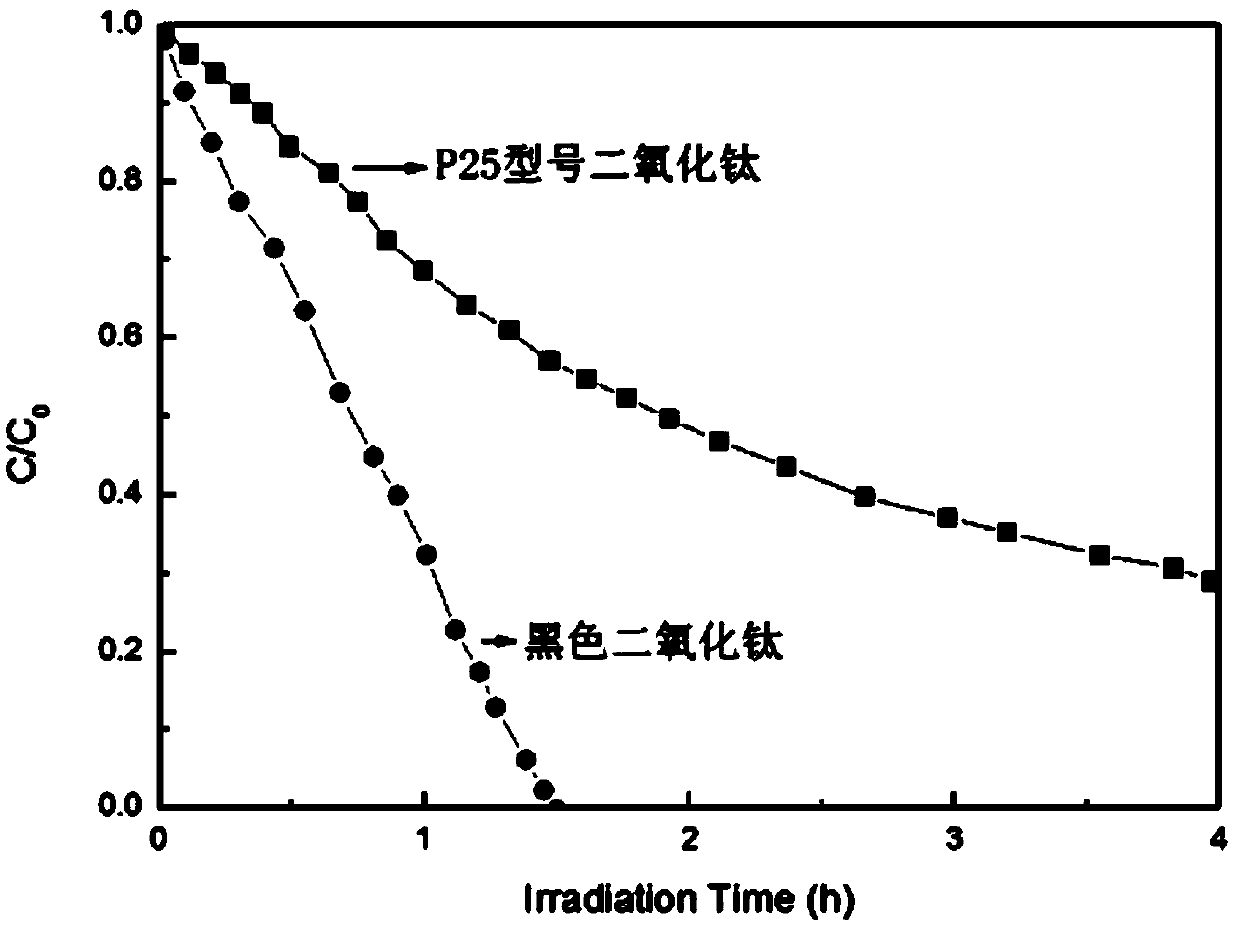

Embodiment 1

[0026] Take 100g of Beijing Haoyun FTiH2 titanium hydride powder sold on the market, 100g of sodium peroxide from Tianjin Damao Reagent Factory, and 100g of water, put them in a beaker, mix them evenly, and add them to the polytetrafluoroethylene lining of the reactor. The degree of filling is 80%. Put the liner into the reactor and tighten the steel cover. The reaction kettle was placed in a constant temperature reactor, the reaction temperature was 200° C., and the reaction time was 5 hours. After the reaction, the obtained product was centrifuged at a speed of 4000r / min and the centrifugation time was 15min, the supernatant was discarded, the precipitate was taken, washed several times with deionized water, and the precipitate was dried in an oven to obtain a black Titanium dioxide powder.

Embodiment 2

[0028] Take 90g of Jinzhou Haotian FTiH2 titanium hydride powder sold on the market, 100g of sodium peroxide from Tianjin Dagu Chemical Industry Co., Ltd., and 100g of water, put them in a beaker, mix them evenly, and add them to the polytetrafluoroethylene lining of the reactor. The degree of filling is 80%. Put the liner into the reactor and tighten the steel cover. The reaction kettle was placed in a constant temperature reactor, the reaction temperature was 200° C., and the reaction time was 5 hours. After the reaction, the obtained product was centrifuged at a speed of 4000r / min and the centrifugation time was 15min, the supernatant was discarded, the precipitate was taken, washed several times with deionized water, and the precipitate was dried in an oven to obtain a black Titanium dioxide powder.

Embodiment 3

[0030] Take the Jinzhou Haixin FTiH sold on the market 2 -80g of type-2 titanium hydride powder, 80g of sodium peroxide from Tianjin Fuchen Chemical Reagent Factory, and 90g of water were placed in a beaker, mixed evenly, and then added to the polytetrafluoroethylene lining of the reaction kettle. The degree of filling is 80%. Put the liner into the reactor and tighten the steel cover. The reaction kettle was placed in a constant temperature reactor, the reaction temperature was 200° C., and the reaction time was 5 hours. After the reaction, the obtained product was centrifuged at a speed of 4000r / min and the centrifugation time was 15min, the supernatant was discarded, the precipitate was taken, washed several times with deionized water, and the precipitate was dried in an oven to obtain a black Titanium dioxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com