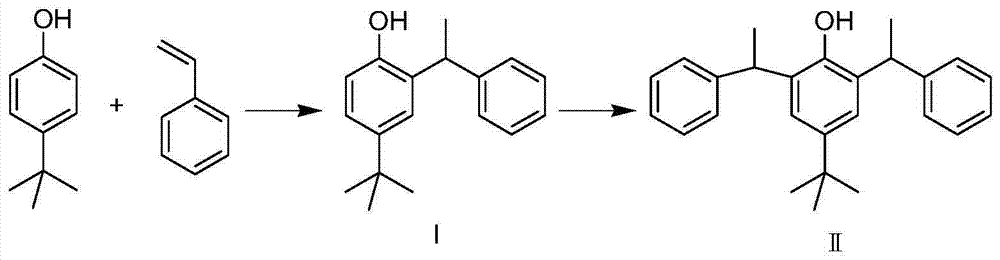

Method for preparing 4-tert-butyl-2-(alpha-methylbenzyl)phenol

A technology of tert-butylphenol and methylbenzyl, which is applied in the field of polymer compound preparation, can solve the problems of unfavorable industrial production, environmental pollution, low yield, etc., achieve easy large-scale industrial production, and improve the total yield and purity , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

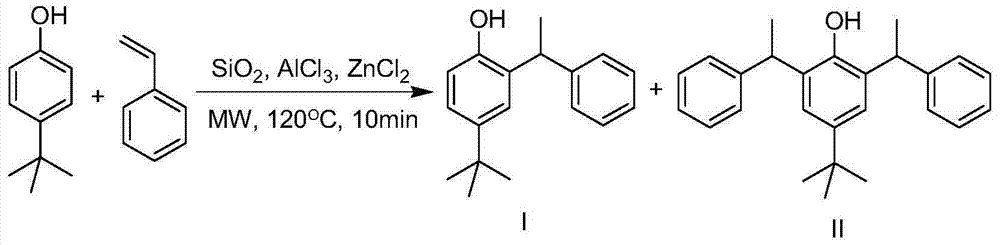

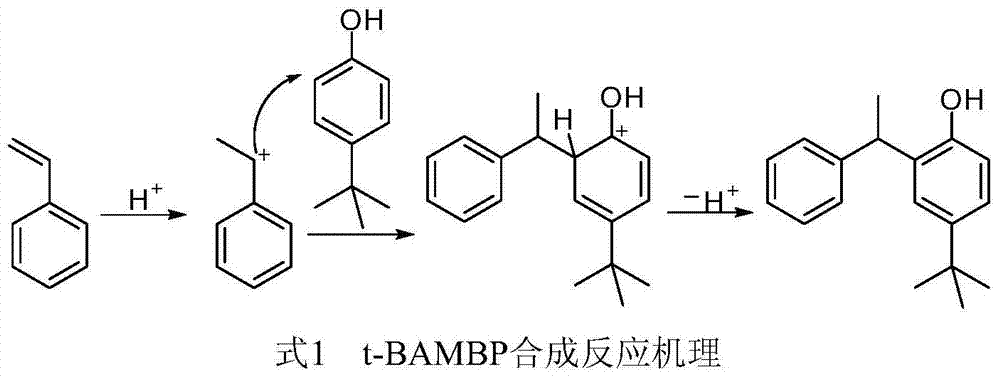

Method used

Image

Examples

Embodiment 1

[0034] Stir 5.0ml of concentrated phosphoric acid (85% by mass) as a catalyst and 6.5ml of phthalic anhydride at room temperature for one hour, stop stirring, add 40.0g of 4-tert-butylphenol, and heat up the oil bath to 110°C When the phenol is completely melted, add 45.0ml of styrene dropwise, keep the drop rate at 1d / s, keep the temperature of the oil bath at 110°C, and raise the system from 110°C to 120°C. After the dropwise addition, the oil bath does not heat up, and the reaction system is heated to 130°C to continue the reaction until the temperature in the system drops slowly, that is, the oil bath is heated to 145°C, and the system is also heated to 145°C, and the reaction is continued for three hours After stopping the reaction. The cooled reaction system was left to stand for separation, and the acid in the lower layer was discarded; the product in the upper layer and the remaining raw materials were directly purified by column chromatography.

[0035] Using petroleum...

Embodiment 2

[0037] Add 100.0ml of concentrated phosphoric acid (85% by mass) and 110.0ml of succinic anhydride into a 500.0ml three-neck flask, put a magnetic stirrer, and react at 50°C. The reaction time is 1.0h, stop the reaction, and proceed directly to the following One step reaction.

[0038] Quickly add 845.0 g of 4-tert-butylphenol into the above mixed acid system from the feeding port, raise the temperature of the system to 110°C while stirring, stop heating the reaction system after the 4-tert-butylphenol is completely melted, and drop Slowly add styrene through the liquid funnel, control the dropping rate to 1d / s, and control the temperature of the system to be basically constant during the dropping process. The amount of styrene added is 905.0ml. After the reaction reaches the end point, cool the reaction system and let it stand for stratification, and use a separatory funnel to completely remove the acid in the lower layer; the upper layer product and the remaining raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com