Vinblastine extraction and purification method

A purification method, the technology of vinblastine, applied in the direction of organic chemistry, etc., can solve the problems of not being able to meet the use requirements, low vinblastine content, etc., and achieve the effect of less time consumption, increased content and yield, and obvious separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

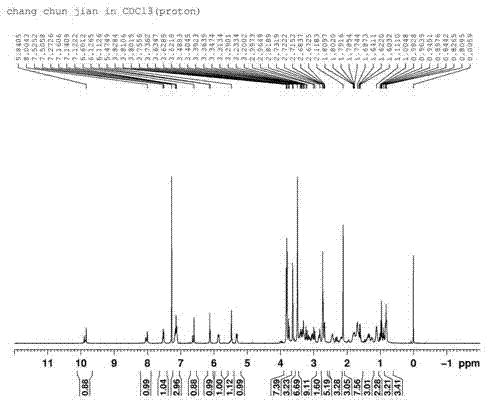

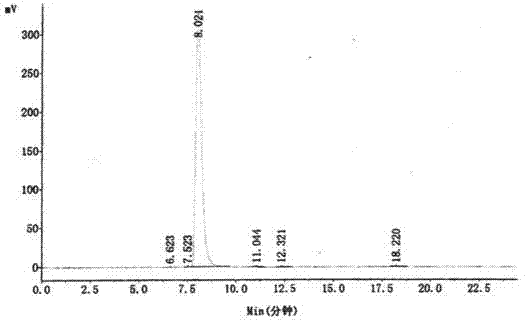

Image

Examples

Embodiment 1

[0038] Using periwinkle (fresh) as raw material, extract and separate vinblastine sulfate according to the following method:

[0039] 1. Extract the crude product of vinblastine sulfate:

[0040] (1) Take 100kg of periwinkle flowers, add them to 900kg of 20% sodium chloride aqueous solution, soak them in ultrasonic for 15 minutes, then take out the periwinkle flowers and put them directly into cold air at -20°C with a flow rate of 6m / s for 20 minutes. Crush the periwinkle.

[0041] (2) Add the periwinkle treated in step (1) to 500kg of 30% ethanol, adjust the pH to 1.5 with citric acid, reflux extraction for 2 hours, filter the filtrate, adjust the pH of the filtrate to 8-9 with sodium hydroxide, and adjust After pH, apply high pressure to the filtrate and spray it from the top of the extraction tank in the form of a spray at a speed of 200 ml / s. The volume ratio is 4.7:1, the filtrate and the extractant are sprayed into the extraction tank at the same time, and the spraying...

Embodiment 2

[0049] Extract vinblastine sulfate crude product according to the method for embodiment 1, difference is: in step (1), the concentration of sodium chloride aqueous solution is 15%, and cold air velocity is 5m / s, and final gained vinblastine sulfate crude product 10.5g, gets The ratio is 0.105‰, and the content of vinblastine sulfate in the crude product is 81.5%.

Embodiment 3

[0051] Extract vinblastine sulfate crude product according to the method for embodiment 1, difference is: in step (1), the concentration of sodium chloride aqueous solution is 25%, and cold air velocity is 8m / s, and final gained vinblastine sulfate crude product 9.2g, gets The ratio is 0.092‰, and the content of vinblastine sulfate in the crude product is 84.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com