Bunker oil emulsifier composition and use thereof

A technology of emulsifier and composition, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of inability to form stable emulsified oil, achieve good emulsification stability, improve emulsification ability, and improve emulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the parts by weight, weigh 19 grams of S-85, 11 grams of T-85, 2 grams of OP-4, 2 grams of n-propanol, 8 grams of n-octanol, 8 grams of PB2400, 2 grams of PEG200, at room temperature 20 ℃ Next, stir for 25 minutes until completely uniform.

[0030] Weighing 2.5% by weight of the bunker oil emulsifier composition and adding it to the bunker oil product, stirring evenly to prepare the oil for experiment, which is set aside. Add 10% by weight of water to the prepared experimental oil, stir for 25min, adopt the standing method to investigate the stability of the emulsion, leave the prepared emulsion at room temperature, record the change over time, the amount of precipitation of water, the same The less water precipitated in the emulsion during the time, the more stable the emulsion.

[0031] The particle size of dispersed phase in emulsifiable concentrate was determined by dynamic light scattering instrument NanoZS. For the emulsion, the smaller the particle...

Embodiment 2~5

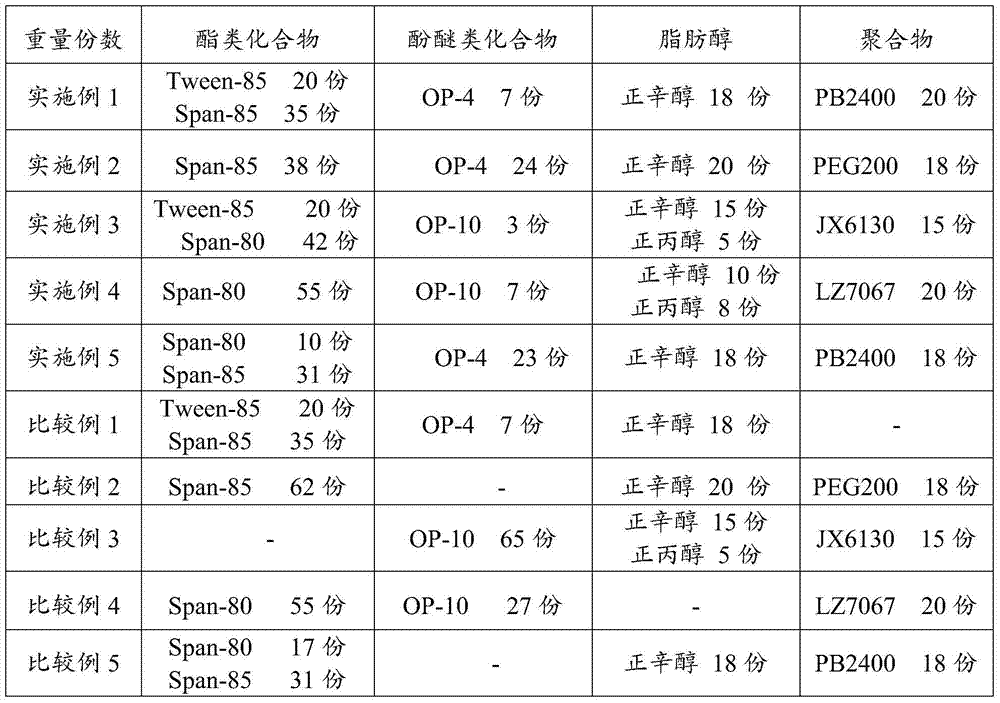

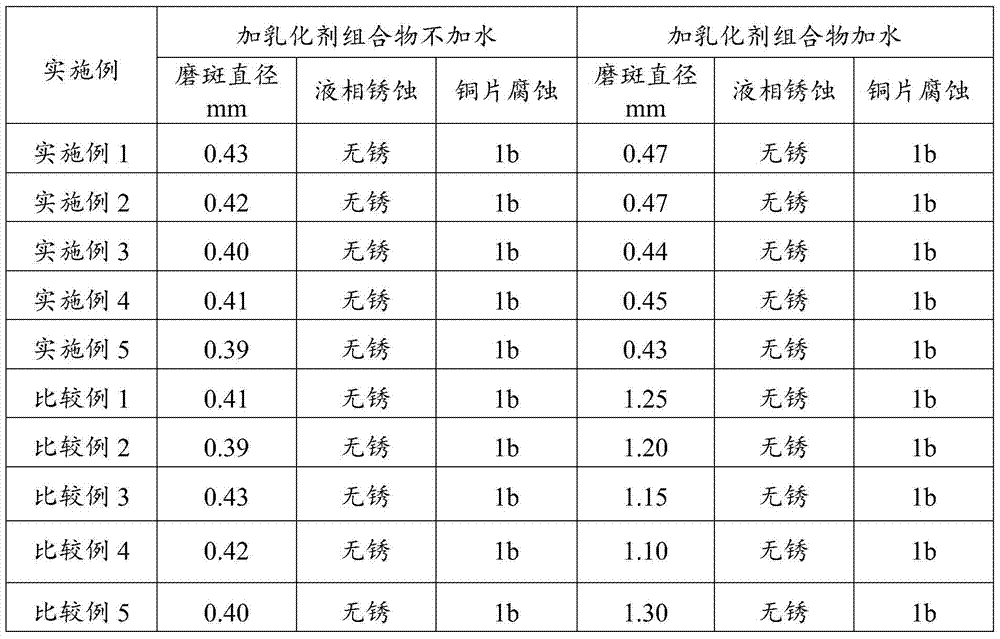

[0035] Prepare bunker oil emulsifier composition and experimental oil by each step of [Example 1], just change the consumption and composition of each component, its bunker oil emulsifier composition composition is shown in Table 1.

[0036] Test the wear scar diameter, liquid phase corrosion and copper sheet corrosion of each experimental oil. The experimental results are shown in Table 2. The experimental oil particle size and static stability test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com