Dry fermentation system and fermentation method thereof

A dry fermentation and fermentation storage technology, applied in the field of agricultural biomass utilization, can solve the problems of easy acidification of local materials, high labor intensity of operation, and influence on gas production efficiency, so as to improve automatic operation function, reduce operation labor intensity, The effect of reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

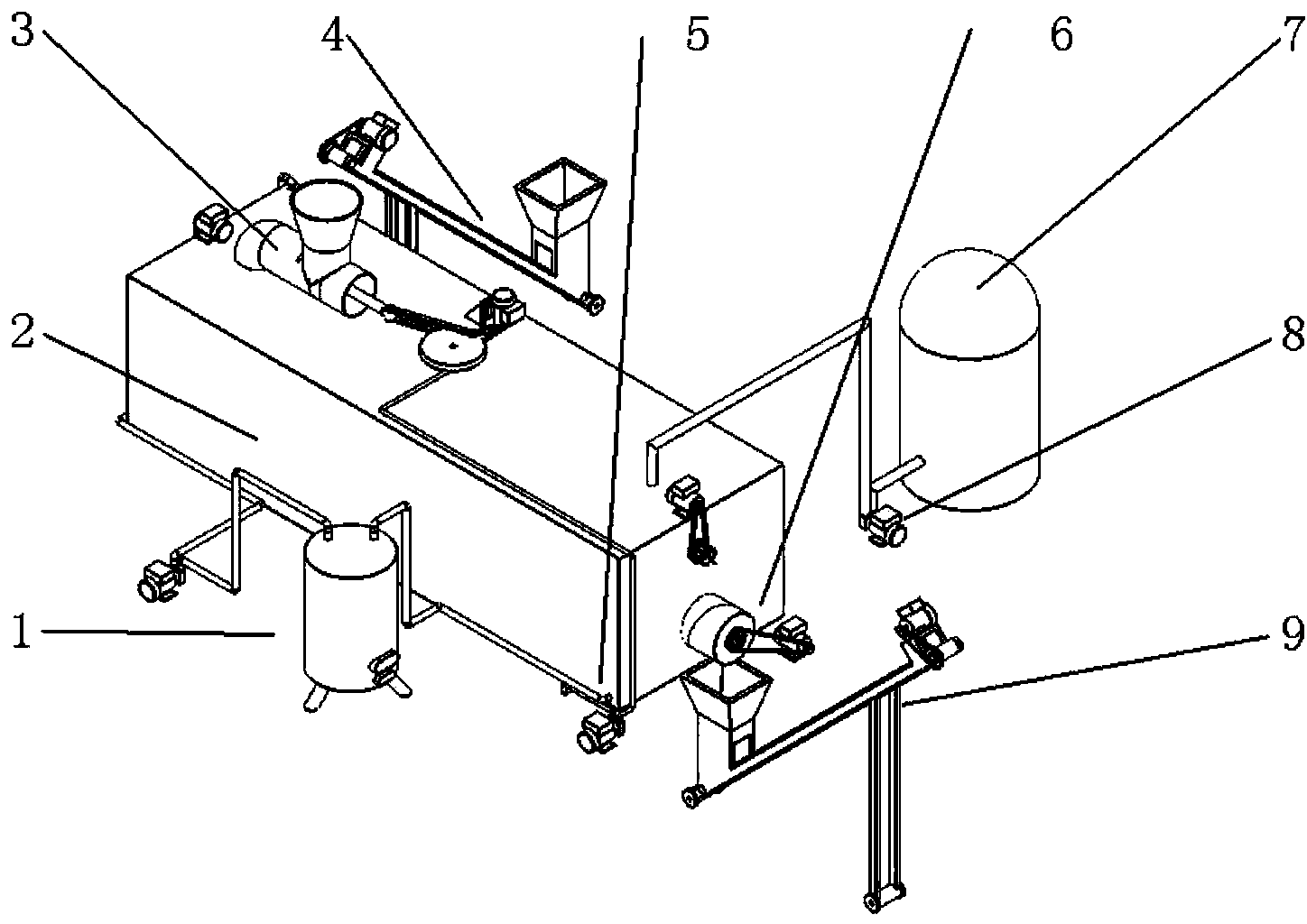

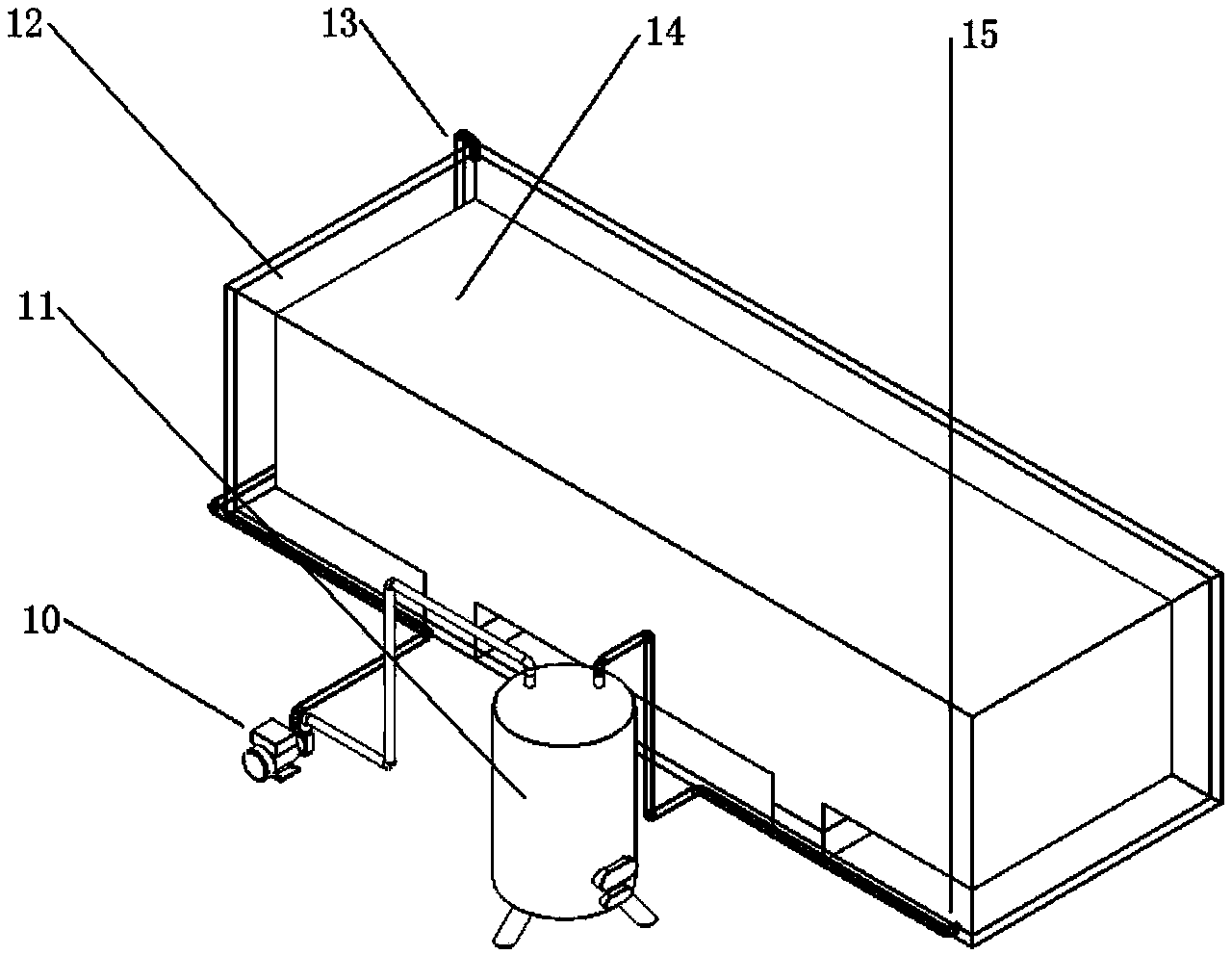

[0032] The basic structure of the dry fermentation system of the present embodiment is mainly as follows figure 1 shown, and see Figure 2 to Figure 9 , including a fermentation storage body 2 having an inlet, a material outlet 45 and an air outlet, and the air outlet is connected to the gas storage tank 7 through a pipeline. The inlet is located on the top side of the fermentation storage body 2, and the discharge port 45 is located at the end of the bottom of the fermentation storage body 2 away from the inlet. see Figure 9 , The bottom of the fermentation storehouse 2 is equipped with a screw conveyor 43 from the bottom of the inlet to the outlet, and a feeding device 3 is installed above the inlet.

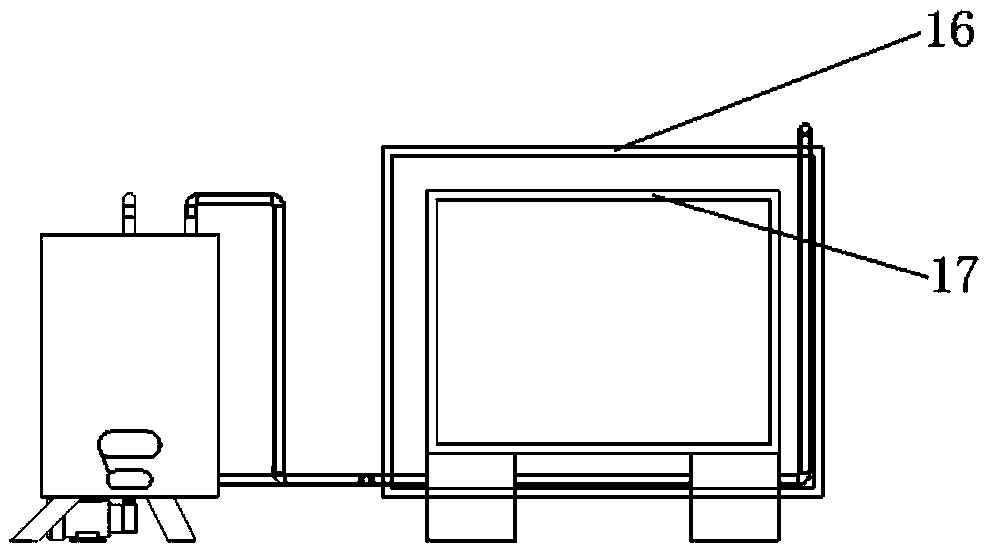

[0033] The concrete structure of feeding device 3 is referring to Figure 4 , Contain elbow shape piston cylinder 18, the vertical section lower end of piston cylinder 18 is communicated with inlet, the piston 19 driven by crank connecting rod reciprocating mechanism 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com