A process for preparing Alticrnita high-entropy alloy coating on the surface of X80 pipeline steel substrate

A high-entropy alloy and substrate surface technology, applied in metal material coating process, coating, vacuum evaporation plating and other directions, can solve the problem of single preparation method of anti-corrosion high-entropy alloy, and achieve excellent corrosion resistance, resistance to Excellent pitting corrosion performance and the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Substrate pretreatment

[0044] Process the X80 pipeline steel into discs with a diameter and thickness of 1.5cm and 3mm respectively, and use 280#, 400#, 600#, 800#, 1200#, 1500# water sandpaper to polish the X80 substrate in turn from coarse to fine, until After smoothing, use acetone and absolute ethanol to ultrasonically clean for 15 minutes respectively.

[0045] (2) Bias backsplash cleaning

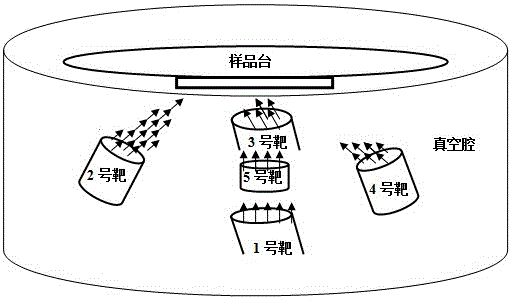

[0046] Deflate the ultra-vacuum multi-functional magnetron co-sputtering equipment until the vacuum degree of the vacuum chamber is atmospheric pressure, open the vacuum chamber, place the above-mentioned processed X80 wafer on the sample stage of the vacuum chamber, first draw a low vacuum with the mechanical pump, and then the molecular pump Pull high vacuum, and then under the condition of -500V voltage, Ar atmosphere, and 1Pa vacuum degree, bias backsplash cleaning for 5min.

[0047] (3) Pre-sputtering

[0048] The targets 1, 2, 3, 4, and 5 of the ultra-vacuum mult...

Embodiment 2

[0056] (1) Substrate pretreatment

[0057] Process the X80 pipeline steel into discs with a diameter and thickness of 1.5cm and 3mm respectively, and use 280#, 400#, 600#, 800#, 1200#, 1500# water sandpaper to polish the X80 substrate in turn from coarse to fine, until After smoothing, use acetone and absolute ethanol to ultrasonically clean for 20 minutes respectively.

[0058] (2) Bias backsplash cleaning

[0059] Deflate the ultra-vacuum multi-functional magnetron co-sputtering equipment until the vacuum degree of the vacuum chamber is atmospheric pressure, open the vacuum chamber, place the above-mentioned processed X80 wafer on the sample stage of the vacuum chamber, first draw a low vacuum with the mechanical pump, and then the molecular pump High vacuum, and then under the condition of -400V voltage, Ar atmosphere, and 2Pa vacuum degree, bias backsplash cleaning for 10min.

[0060] (3) Pre-sputtering

[0061] The targets 1, 2, 3, 4, and 5 of the ultra-vacuum multi-fu...

Embodiment 3

[0069] (1) Substrate pretreatment

[0070]Process the X80 pipeline steel into discs with a diameter and thickness of 1.5cm and 3mm respectively, and use 280#, 400#, 600#, 800#, 1200#, 1500# water sandpaper to polish the X80 substrate in turn from coarse to fine, until After smoothing, use acetone and absolute ethanol to ultrasonically clean for 20 minutes respectively.

[0071] (2) Bias backsplash cleaning

[0072] Deflate the ultra-vacuum multi-functional magnetron co-sputtering equipment until the vacuum degree of the vacuum chamber is atmospheric pressure, open the vacuum chamber, place the above-mentioned processed X80 wafer on the sample stage of the vacuum chamber, first draw a low vacuum with the mechanical pump, and then the molecular pump Pull high vacuum, and then under the condition of -450V voltage, Ar atmosphere, and 1.5Pa vacuum degree, bias backsplash cleaning for 10min.

[0073] (3) Pre-sputtering

[0074] The targets 1, 2, 3, 4, and 5 of the ultra-vacuum mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com