Exterior wall external thermal insulation coating veneer structure

A technology for external insulation and coating of external walls, applied in building components, fire prevention, etc., can solve problems such as hidden safety hazards, external insulation structure shedding, difficult heat conduction and diffusion, etc., to improve service life, excellent thermal insulation performance, and low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

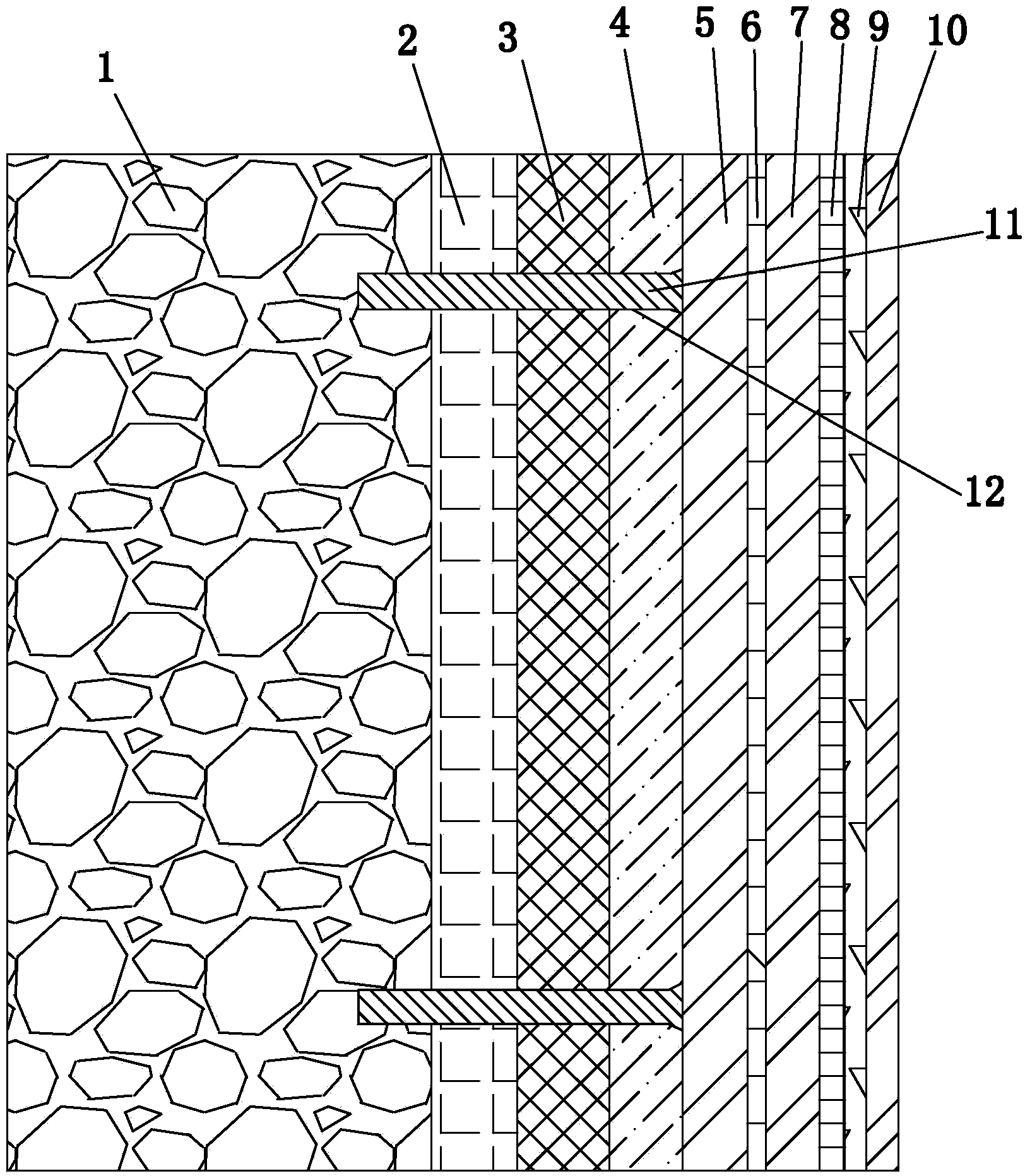

[0028] refer to figure 1 A further description will be given to an embodiment of the decorative surface structure of an exterior thermal insulation paint of the present invention.

[0029] Various raw materials used in the examples are commercially available industrial products. The tools and equipment used to practice the invention are common to the paint and construction industries.

[0030] A kind of finish structure of exterior thermal insulation coating of the present invention:

[0031] First, a layer of adhesive layer 2 is evenly coated on the base wall 1. The adhesive layer 2 is thermal insulation adhesive mortar. The thermal insulation adhesive mortar used is produced by Yixing Hongbo Packaging Co., Ltd., and its brand is HB-1. It is composed of dispersed latex powder, quartz sand, cement, polypropylene short fiber and synthetic fiber. It has good water retention and high bonding strength. When in use, add 20% to 30% (weight) to the bonding mortar powder. The wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com