Chemically modified carbon paste electrode as well as preparation method and application thereof

A carbon paste electrode and chemical modification technology, applied in the field of electrochemical analysis, can solve the problems that the detection limit is not low enough, can not meet the monitoring of surface water quality, hinder the commercial development of heavy metal ion carbon paste electrode, etc. The electrode is easy to update and the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

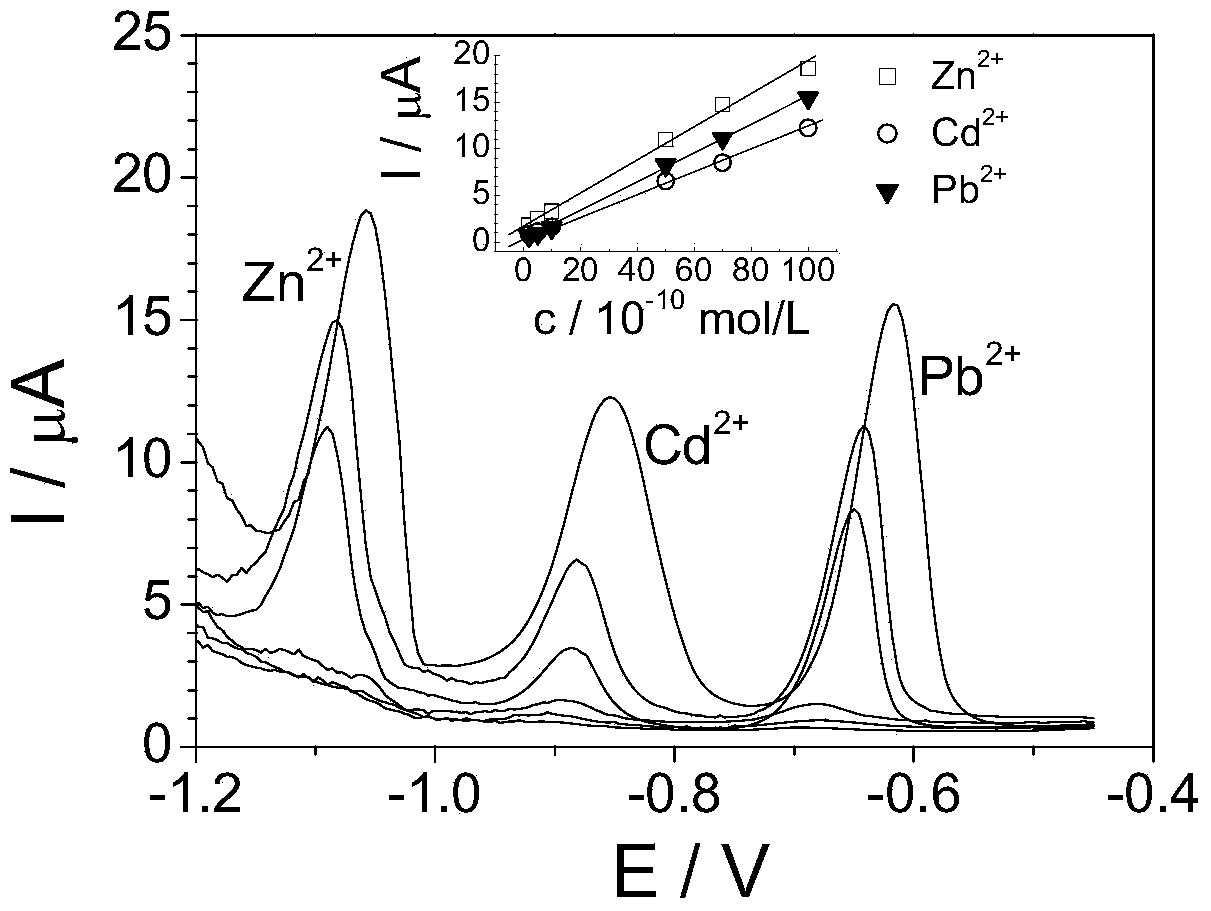

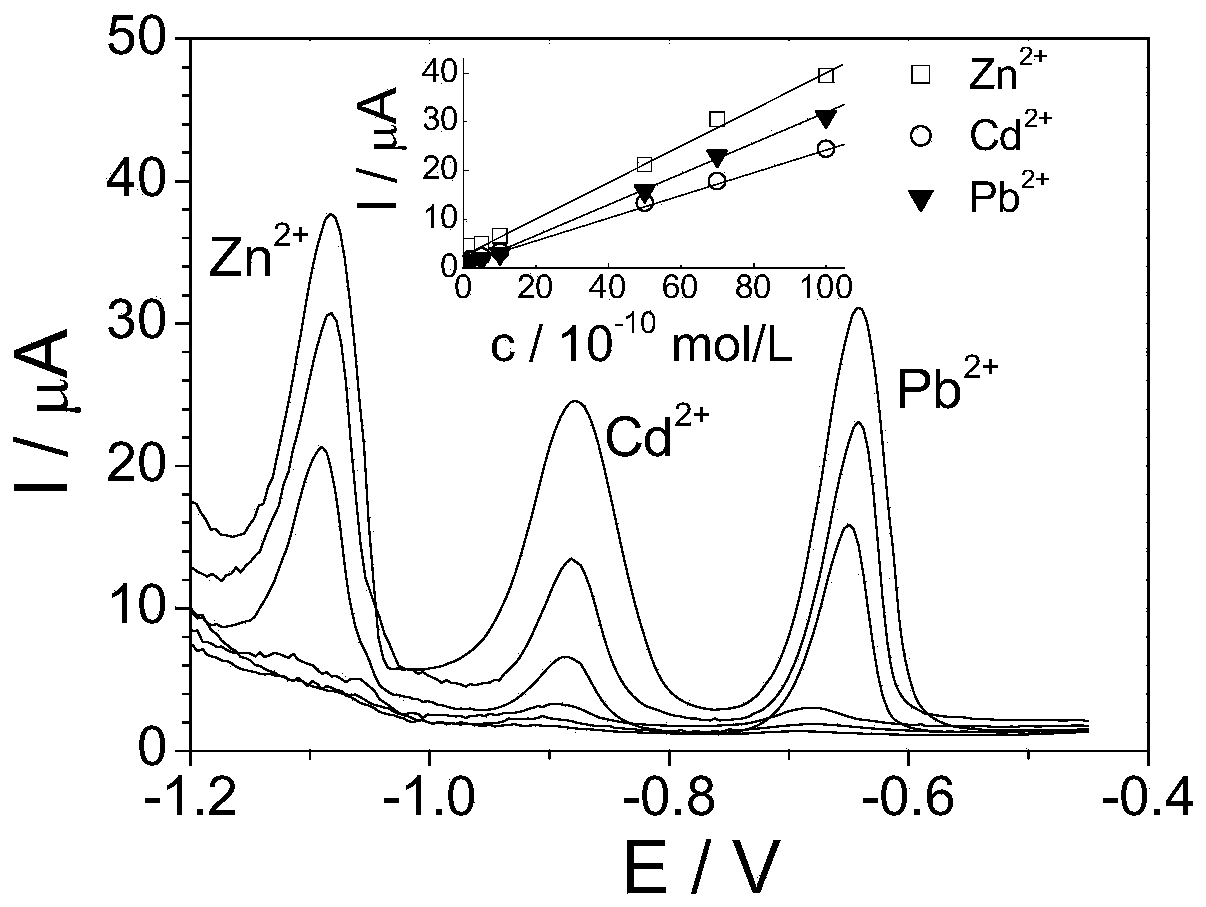

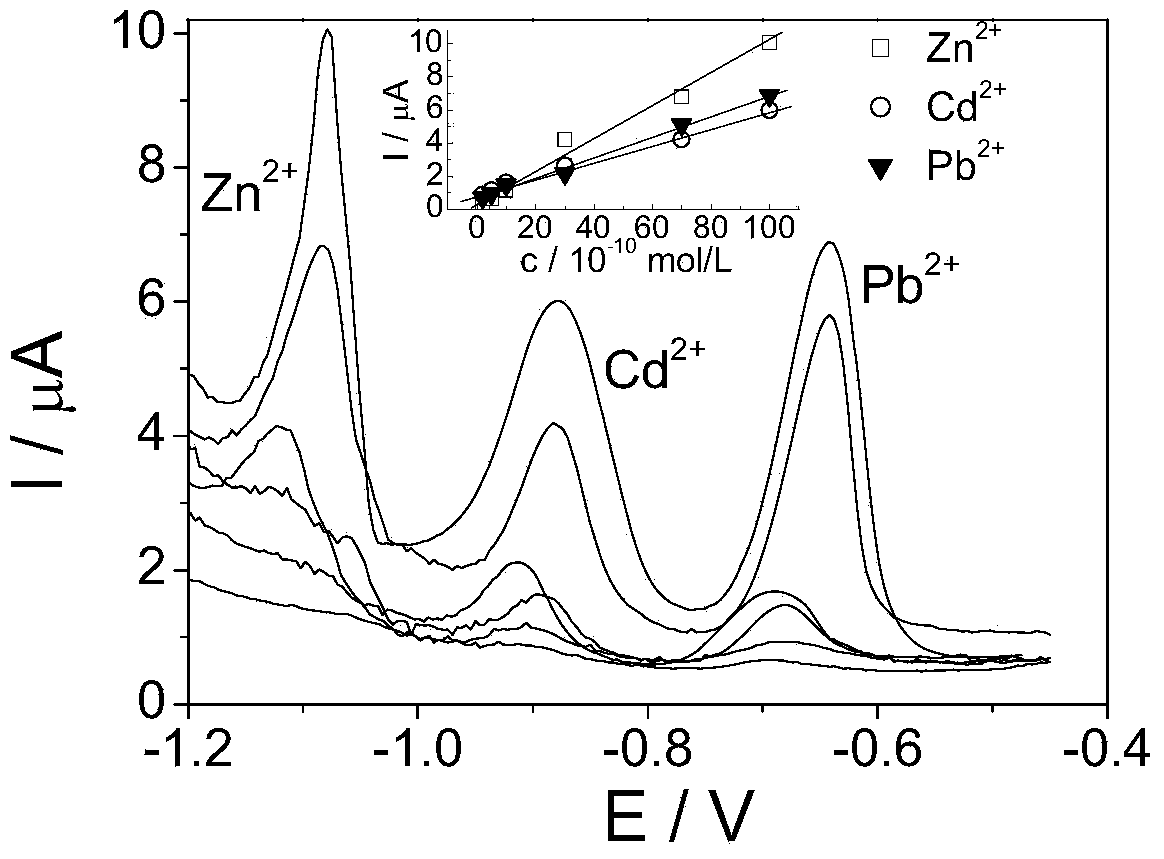

Image

Examples

Embodiment 1

[0049] A method for preparing a chemically modified carbon paste electrode, comprising the steps of:

[0050] (1) First, take a 100mL mortar, and then add 10.0mg of bismuth oxide powder into the mortar;

[0051] (2) Measure 1 mL of ethanol and add it to the mortar, wherein the 1 mL of ethanol contains 5 mg of dimethylglyoxime, and stir the bismuth oxide powder and dimethylglyoxime in the grinding body to form a paste to obtain a composite modifier;

[0052] (3) After the ethanol is completely volatilized, add 60 mg of graphite powder in the mortar and stir evenly; then add 10 mg of methyl silicone oil and stir to obtain the required carbon paste;

[0053] (4) Take a polytetrafluoroethylene tube with an inner diameter of 2mm, an outer diameter of 5mm, and a length of 40mm as the electrode shell, and polish both ends on sandpaper, clean it by ultrasonic cleaning, dry it, and set it aside;

[0054] (5) The carbon paste that step (3) is made tightly fills in the cleaned polytetra...

Embodiment 2

[0056] A method for preparing a chemically modified carbon paste electrode, comprising the steps of:

[0057] (1) First, take a 100mL mortar, and then add 2mg of bismuth oxide powder into the mortar;

[0058] (2) Measure 2 mL of benzene and add it to the mortar, wherein the 2 mL of benzene contains 2 mg of dithizone, and stir the bismuth oxide powder and dithizone in the grinding body to form a paste to obtain a composite modifier;

[0059] (3) After the benzene is completely volatilized, add 70 mg of mesoporous carbon powder in the mortar and stir evenly; then add 30 mg of paraffin oil and stir to obtain the required carbon paste;

[0060] (4) Take a glass tube with an inner diameter of 2 mm, an outer diameter of 4 mm, and a length of 40 mm as the electrode shell, and smooth both ends on sandpaper, clean it with ultrasonic waves, dry it, and set aside;

[0061] (5) Fill the carbon paste prepared in step (3) tightly into the cleaned glass electrode shell, insert a copper wire...

Embodiment 3

[0063] A method for preparing a chemically modified carbon paste electrode, comprising the steps of:

[0064] (1) First, take a 25mL mortar, and then add 50mg of bismuth hydroxide powder, 30mg of benzoin oxime and 20mg of fullerene into the mortar, and stir well, wherein the bismuth hydroxide powder and benzoin oxime Composition of composite modifiers;

[0065] (2) Add 50mg of mineral oil in the beaker, stir evenly, and make the required carbon paste;

[0066] (3) Take a plastic tube with an inner diameter of 2 mm, an outer diameter of 5 mm, and a length of 40 mm as the electrode shell, and smooth both ends on sandpaper, clean it with ultrasonic waves, dry it, and set aside;

[0067] (4) Fill the carbon paste prepared in step (2) tightly into the cleaned plastic electrode shell, insert a copper wire with a diameter of 2 mm and a length of 50 mm at one end of the electrode nozzle, so that the 20 mm copper wire is exposed to the electrode. The outside of the shell is used as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com