Preparation method of cobalt phosphate powder material

A technology of cobalt phosphate powder and bulk material, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high cost, low yield and high impurity content, and achieves low cost, simple preparation process and high impurity content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to one aspect of the present invention, a kind of preparation method of cobalt phosphate powder material is provided, and the method comprises the following three steps:

[0029] Step 1. Add soluble cobalt salt to the water in container I to prepare aqueous solution A, and add soluble phosphate to the water in container II to prepare aqueous solution B.

[0030] In the above step 1, the soluble cobalt salt is one or more of cobalt chloride, cobalt nitrate and cobalt sulfate.

[0031] Among them, the chemical formula of cobalt chloride specifically mentions: CoCl 2 and CoCl 2 6H 2 O; the chemical formula of cobalt nitrate is specifically mentioned: Co(NO 3 ) 2 ·6H 2 O; the chemical formula of cobalt sulfate specifically mentions: CoSO 4 ·7H 2 O.

[0032] In one of the above steps, the soluble phosphate is one or more of ammonium dihydrogen phosphate, diammonium hydrogen phosphate, sodium dihydrogen phosphate, disodium hydrogen phosphate, potassium dihyd...

Embodiment 1

[0066] 1) Weigh 84.0g CoSO 4 ·7H 2 O was added to 734mL of deionized water in container I to prepare aqueous solution A, and 26.4g (NH 4 ) 2 HPO 4 Add it to 734mL of deionized water in container II to make aqueous solution B;

[0067] 2) Add the aqueous solution B to the aqueous solution A, the reaction temperature is 25° C., and the stirring rate is 200 rpm. After the reaction is completed, the reaction temperature remains unchanged, and ammonia water is added to adjust the reaction system so that the reaction system is neutral;

[0068] 3) Suction filter the reaction system obtained in step 2, wash twice with deionization, then dry at 120°C for 24 hours, and finally pass through a 300-mesh sieve to obtain cobalt phosphate powder material.

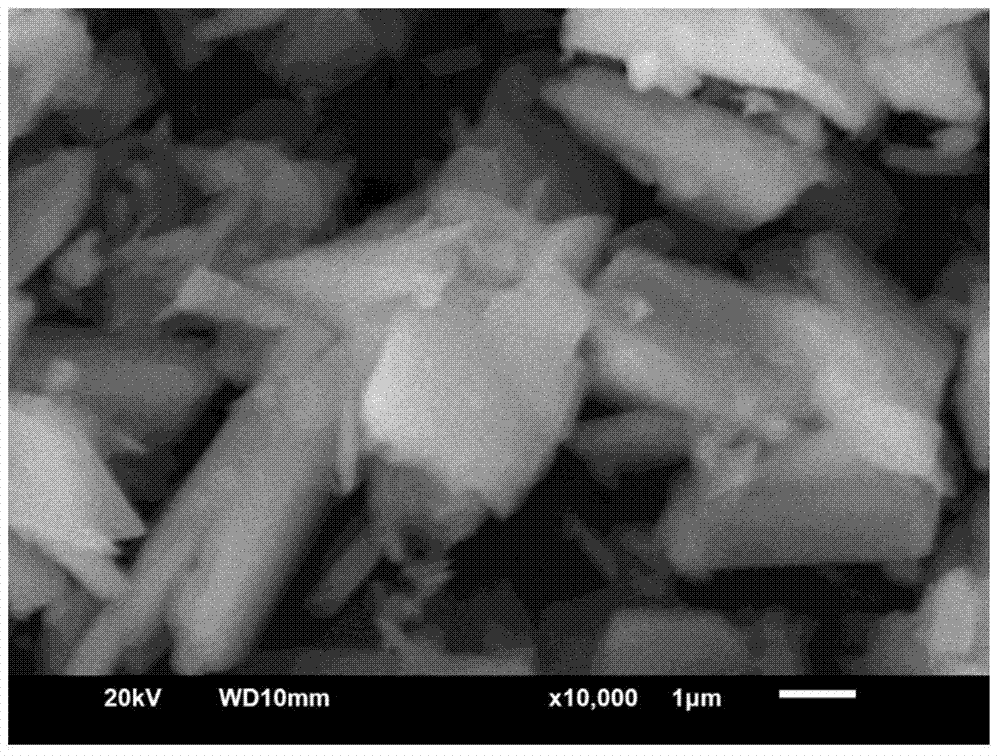

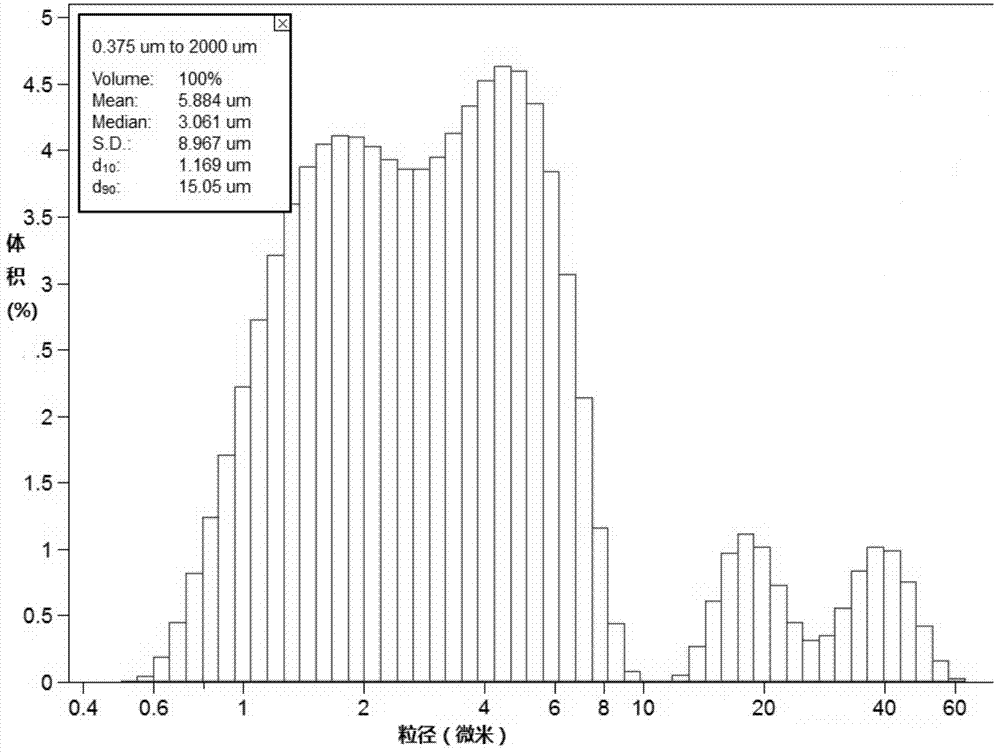

[0069] Measured by a Beckman particle size tester: the median diameter (D50) of the obtained cobalt phosphate powder material is 3.1 microns, D10 is 1.2 microns, and D90 is 15.1 microns.

[0070] After ICP detection, the impurity con...

Embodiment 2

[0074] 1) Weigh 87.3gCo(NO 3 ) 2 ·6H 2 O was added to 200mL of deionized water in container I to prepare aqueous solution A, and 26.4g (NH 4 ) 2 HPO 4 Add it to 150mL of deionized water in container II to make aqueous solution B;

[0075] 2) Add aqueous solution B to aqueous solution A at a rate of 3ml / min, the reaction temperature is 60°C, and the stirring rate is 100rpm. After the reaction is completed, the reaction temperature remains unchanged, and the reaction system is adjusted by adding ammonia water dropwise, so that the reaction system is neutral , after adding ammonia water, continue to stir for 0.5h;

[0076] 3) Suction filter the reaction system obtained in step 2, wash with deionization for 3 times, then dry at 150° C. for 24 hours, and finally pass through a 300-mesh sieve to obtain cobalt phosphate powder material.

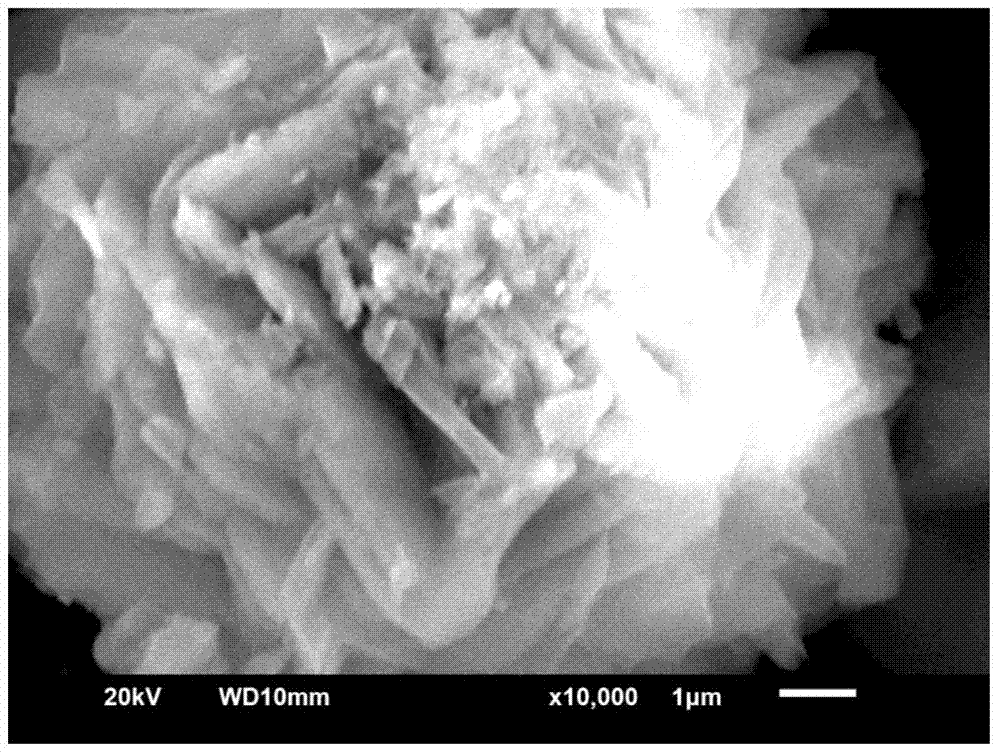

[0077] Measured by a Beckman particle size tester: the median diameter (D50) of the obtained cobalt phosphate powder material is 12.7 microns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com