Surface modified metal connector of solid oxide fuel battery and manufacturing method of surface modified metal connector

A technology of solid oxide and metal connectors, which is applied in the field of surface modified metal connectors and its manufacture, fuel cell connectors and their surface modification, and can solve the problem of insufficient bonding between the modified layer and the substrate, delamination and peeling, etc. problems, to achieve excellent interfacial compatibility, good electronic conductivity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

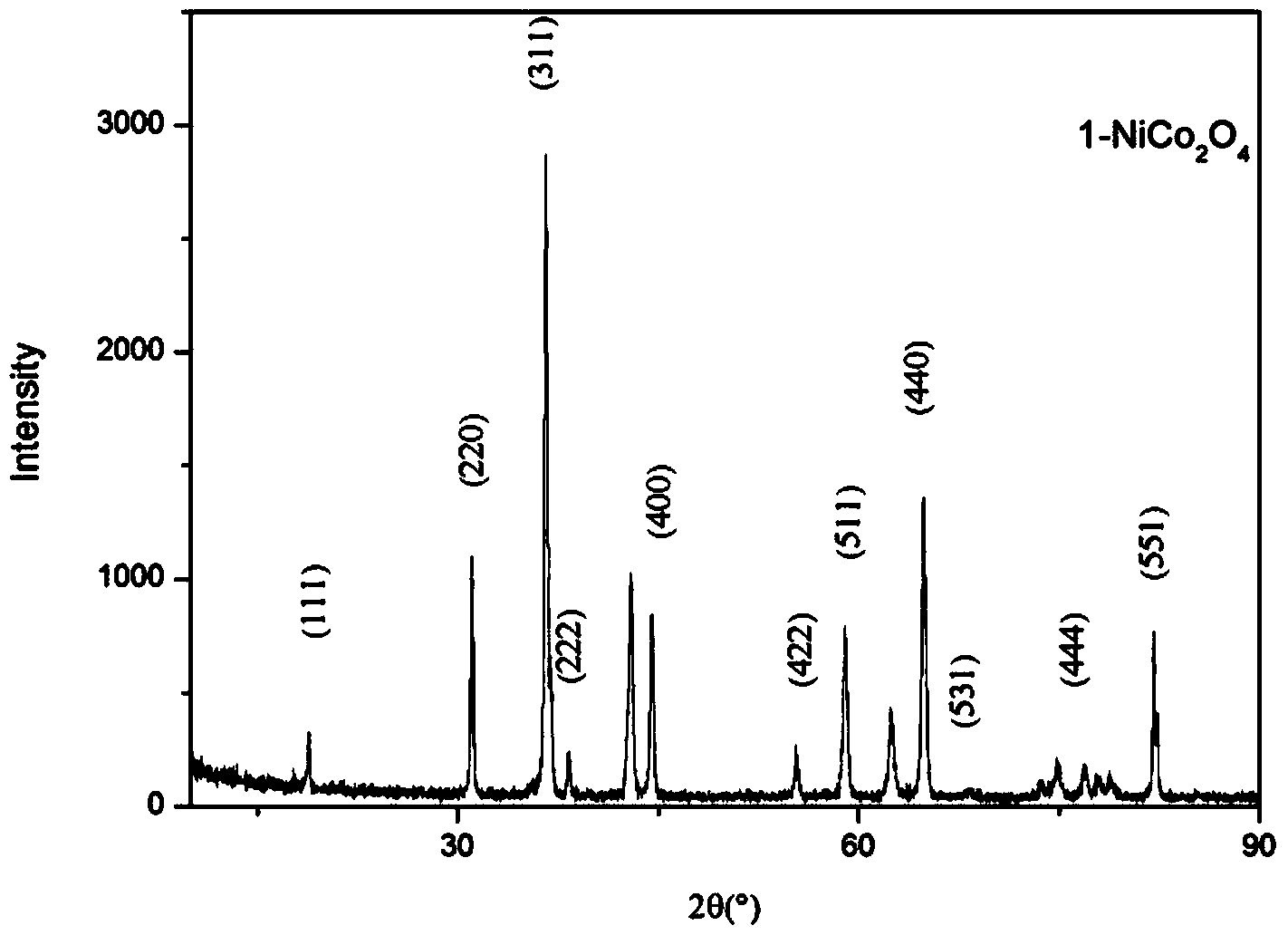

Embodiment 1

[0017] A 0.5mm stainless steel plate of AISI 430 (with a Cr content of 17wt%) was used as the matrix, and the matrix structure was ferrite. Cut the 430 stainless steel plate into a sample with a size of 40x 40mm; then process the sample in the stamping equipment to form a gas flow field on both sides of the sample; and successively use dilute NaOH solution, acetone, etc. to clean the surface of the sample to remove the surface pollutants. Put the sample into a special vacuum container and first carry out infiltration and alloying treatment, and obtain a Co-Ni infiltration and alloying layer on the surface of the 430 stainless steel connector. The specific implementation is as follows: put the 430 stainless steel connecting body into a closed container as the cathode, and after the container is evacuated, argon is introduced as the working gas to keep the pressure in the furnace at 35Pa, and a 650V pulsed DC voltage is applied to the connecting body sample, and the metal 550V ...

Embodiment 2

[0018] Cut an AISI 430 (17wt% Cr) stainless steel plate with a thickness of 2.5 mm into a sample of 40 x 40 mm, form a gas flow field on both sides, and process it according to the steps in Example 1. The specific implementation is as follows: put the 430 stainless steel connecting body into a closed container as the cathode, and after the container is evacuated, hydrogen gas is introduced as the working gas to keep the pressure in the furnace at 1050Pa, and a pulsed DC voltage of 780V is applied to the connecting body sample, and the metal Co , Apply 850V pulsed DC voltage on the Mn source, and the current density is 12mA / cm 2 , to generate a glow discharge so that the metal source metal Co and Mn atoms are bombarded out, and a plasma atmosphere containing Co and Mn metal ions is formed to bombard the surface of the connected body sample. The temperature of the connected body sample is controlled at 950 ° C for 2 hours to make the connected body The surface of the sample form...

Embodiment 3

[0020] The 0Cr12 (12wt% Cr content) ferritic stainless steel plate with a thickness of 1.2mm was cut into a sample of 40x40mm, and the gas flow field was stamped and formed on both sides, and processed according to the steps of Example 1. The specific implementation is as follows: put the 0Cr12 stainless steel connector into a closed container as the cathode, and after the container is evacuated, a mixed gas of hydrogen and argon is introduced, the mixing ratio is 1:1, and as the working gas, the pressure in the furnace is maintained at 550Pa. Apply a pulsed DC voltage of 900V to the connected body sample, and apply a pulsed DC voltage of 880V to the metal Co source, with a current density of 5mA / cm 2 , to generate a glow discharge so that the metal source metal Co atoms are bombarded out, and a plasma atmosphere containing Co metal ions is formed to bombard the surface of the connected body sample. The temperature of the connected body sample is controlled at 850 ° C for 4 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com