Scale cleaning agent and preparation method thereof

A cleaning agent and scale technology, applied in the field of scale cleaning agent and its preparation, can solve problems such as equipment corrosion, and achieve the effects of alleviating corrosion, excellent cleaning performance and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare a limescale cleaner according to the following recipe:

[0032] components

weight percentage (%)

Hydrochloric acid with a mass concentration of 37%

15

0.1

1

Coconut Oil Fatty Acid Diethanolamide

1

0.5

0.4

2

water

80

[0033] The preparation method of the present embodiment is as follows:

[0034] (1) add 50% water of total water amount in reactor, at normal temperature, add mass concentration while stirring and be the hydrochloric acid of 37%, leave standstill after dissolving completely;

[0035] (2) Add mercaptobenzothiazole and sodium sulfite respectively to the hydrochloric acid solution prepared in step (1), after stirring evenly, add coconut oil fatty acid diethanolamide, fulvic acid and citric acid, and continue stirring until the solution is uniformly dispersed;

[0036] (3) Me...

Embodiment 2

[0038] Prepare a limescale cleaner according to the following recipe:

[0039] components

weight percentage (%)

Sulfuric acid with a mass concentration of 98%

5

0.5

citric acid

5

Sorbitan monopalmitate

0.5

[0040] Benzotriazole

3.5

0.6

0.5

water

84.4

[0041] The preparation method of the present embodiment is as follows:

[0042] (1) add the water of 50% of total water amount in reactor, at normal temperature, add the sulfuric acid that mass concentration is 98% while stirring, leave standstill after dissolving completely;

[0043] (2) Add benzotriazole and sodium sulfite respectively to the sulfuric acid solution prepared in step (1), after stirring evenly, add sorbitan monopalmitate, fulvic acid and citric acid, and continue to stir until the solution is uniformly dispersed;

[0044] (3) Melt the polyacrylamide with the...

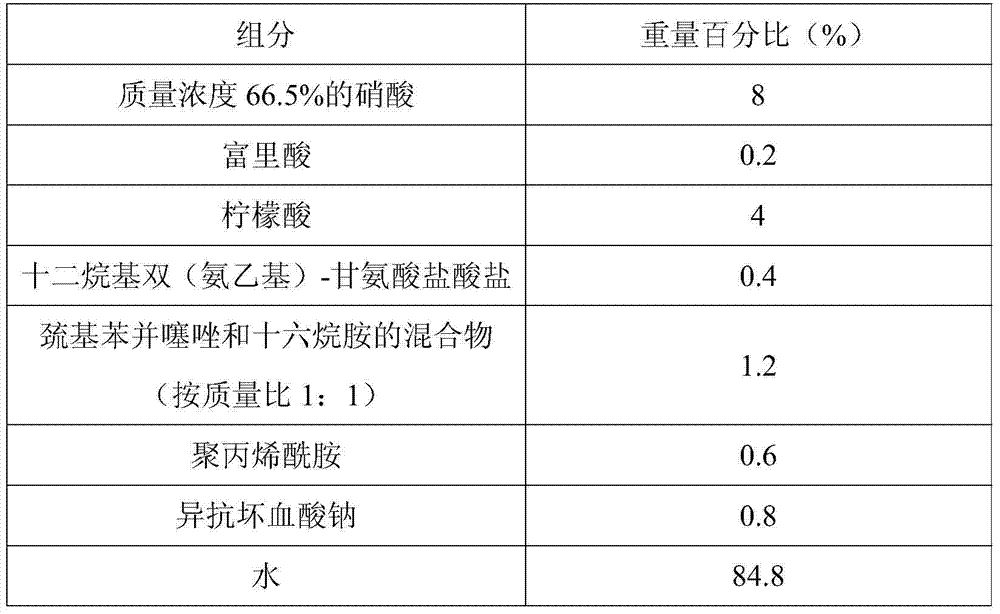

Embodiment 3

[0046] Prepare a limescale cleaner according to the following recipe:

[0047]

[0048] The preparation method of the present embodiment is as follows:

[0049] (1) add the water of total water yield 50% in reactor, at normal temperature, add the nitric acid that mass concentration is 66.5% while stirring, leave standstill after dissolving completely;

[0050] (2) In the nitric acid solution prepared in step (1), add respectively a mixture of mercaptobenzothiazole and cetylamine in a mass ratio of 1:1 and sodium erythorbate, after stirring evenly, then add dodecylbis( Aminoethyl)-glycine hydrochloride, fulvic acid and citric acid, continue to stir until the solution is evenly dispersed;

[0051] (3) Melt the polyacrylamide with the remaining 50% of water to form a viscous uniform liquid, pour it into the mixed solution prepared in step (2) while stirring, and stir evenly to obtain the finished scale cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com