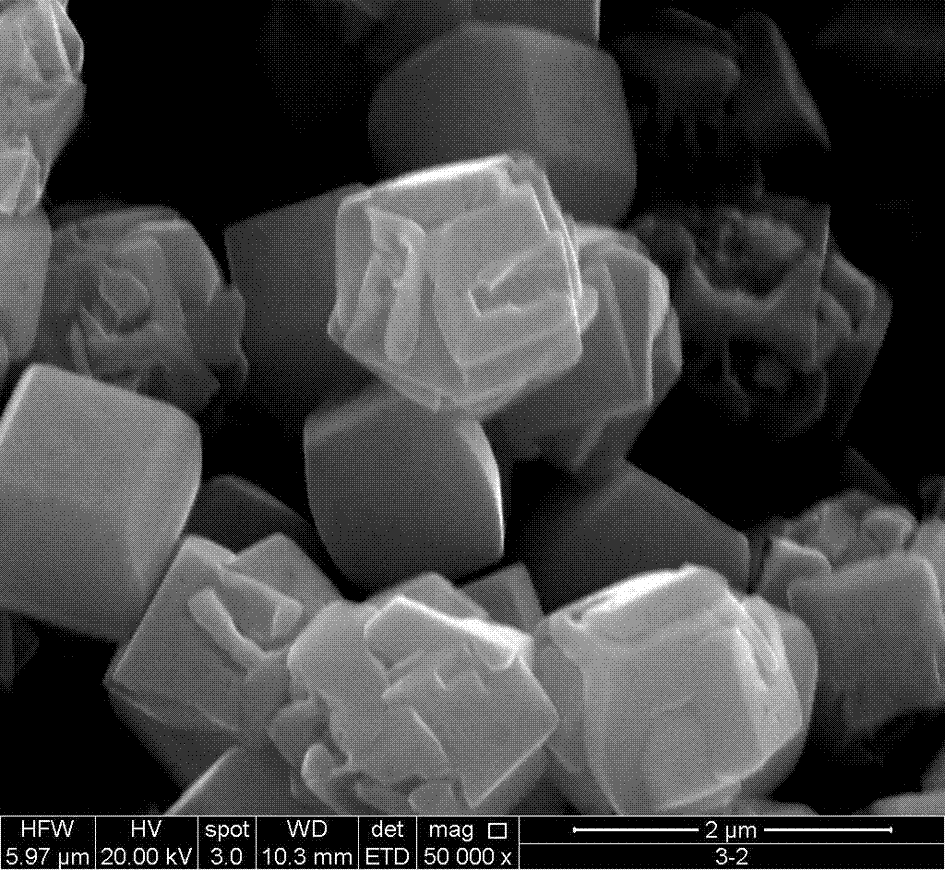

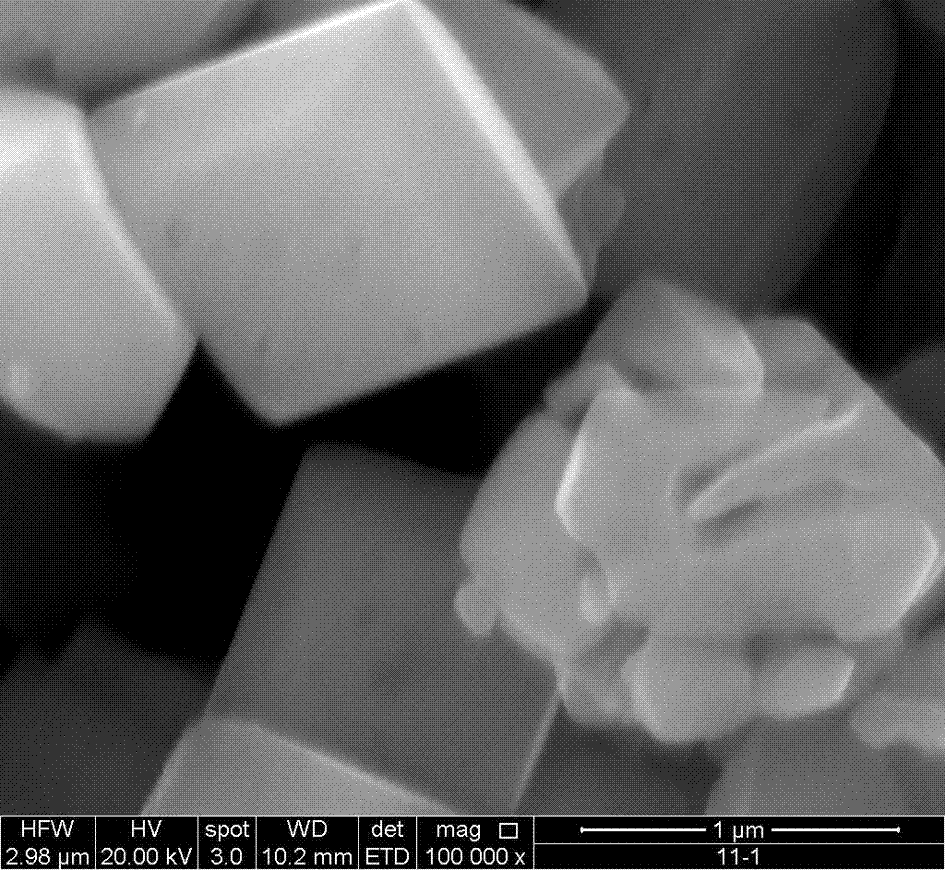

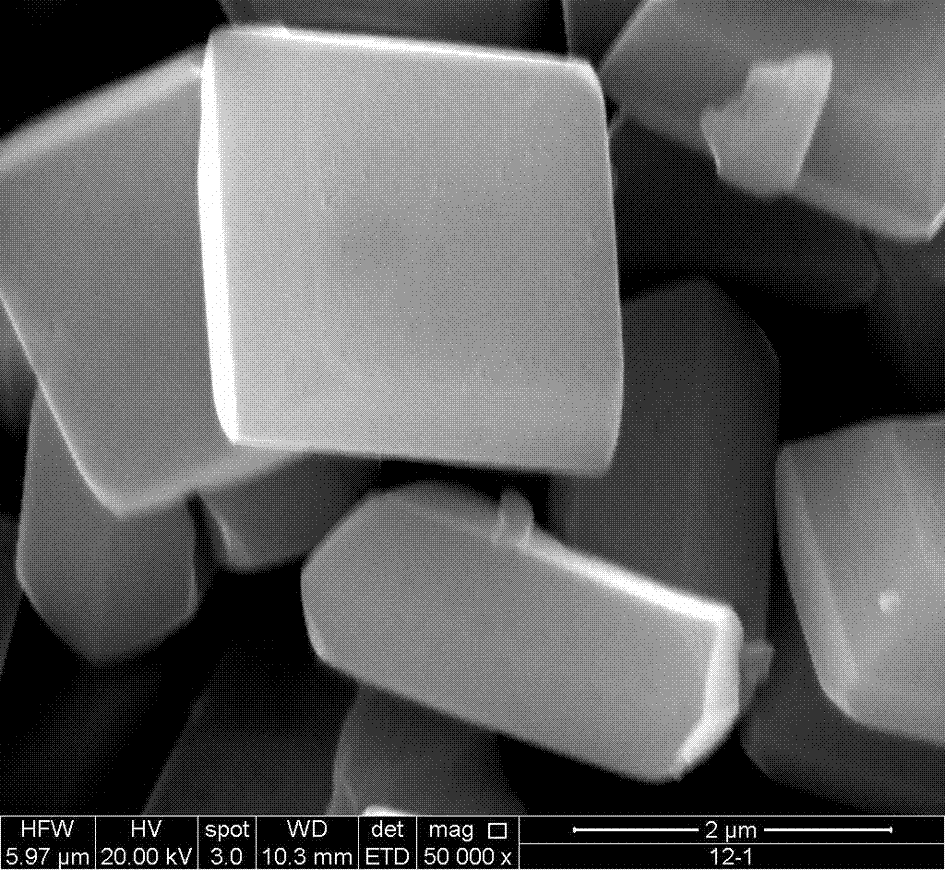

Preparation method of titanium dioxide microspheres in poly-crystal face platy-monocrystal structures

A flake single crystal, titanium dioxide technology, applied in the field of nanomaterials, can solve problems such as orientation affecting crystal growth, increase material preparation cost and process difficulty, etc., and achieve the effects of low cost, simple method and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of polycrystalline sheet-like single crystal structure titanium dioxide microspheres, the preparation method comprising the following steps:

[0021] Step 1, preparation of aqueous precursor solution: adding titanyl sulfate to water to prepare titanyl sulfate aqueous solution; adding fluorine-containing reagent to titanyl sulfate aqueous solution, so that the molar ratio of fluorine and titanium in the resulting mixed solution is 16:1- 24:1, which is the aqueous solution of the precursor, for later use;

[0022] The fluorine-containing reagent is hydrogen fluoride aqueous solution, sodium fluoride solid or sodium fluoride aqueous solution;

[0023] Step 2. Take the precursor aqueous solution prepared in the above step 1 and add it to the reactor according to the ratio of the volume of the precursor aqueous solution to the volume of the reactor at a ratio of 7:10. After incubation at 180° C. for 12 hours, naturally cool to room temperature to obtain ...

Embodiment 1

[0028] A preparation method of polycrystalline sheet-like single crystal structure titanium dioxide microspheres, the preparation method comprising the following steps:

[0029] Step 1, preparation of aqueous precursor solution: adding titanyl sulfate to water to prepare titanyl sulfate aqueous solution; adding fluorine-containing reagent to titanyl sulfate aqueous solution, so that the molar ratio of fluorine and titanium in the resulting mixed solution is 16:1- 24:1, which is the aqueous solution of the precursor, for later use;

[0030] The fluorine-containing reagent is hydrogen fluoride aqueous solution, sodium fluoride solid or sodium fluoride aqueous solution;

[0031] Step 2. Take the precursor aqueous solution prepared in the above step 1 and add it to the reactor according to the ratio of the volume of the precursor aqueous solution to the volume of the reactor at a ratio of 7:10. After incubation at 180° C. for 12 hours, naturally cool to room temperature to obtain ...

Embodiment 2

[0035] A preparation method of polycrystalline sheet-like single crystal structure titanium dioxide microspheres, the preparation method comprising the following steps:

[0036] Step 1, preparation of aqueous precursor solution: adding titanyl sulfate to water to prepare titanyl sulfate aqueous solution; adding fluorine-containing reagent to titanyl sulfate aqueous solution, so that the molar ratio of fluorine and titanium in the resulting mixed solution is 16:1- 24:1, which is the aqueous solution of the precursor, for later use;

[0037] The fluorine-containing reagent is hydrogen fluoride aqueous solution, sodium fluoride solid or sodium fluoride aqueous solution;

[0038] Step 2. Take the precursor aqueous solution prepared in the above step 1 and add it to the reactor according to the ratio of the volume of the precursor aqueous solution to the volume of the reactor at a ratio of 7:10. After incubation at 180° C. for 12 hours, naturally cool to room temperature to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap