High performance lithium titanate power battery

A high-performance lithium titanate and power battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as short cycle life, insufficient, poor safety performance, etc., to improve cycle life, slow down negative electrode expansion, and ensure safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

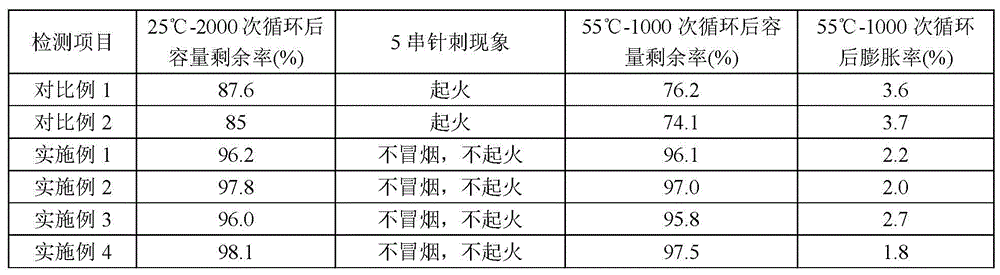

Examples

Embodiment 1

[0028] Prepare the positive electrode sheet: mix 90 parts by weight of nickel cobalt lithium manganese oxide, 2 parts by weight of conductive carbon black SP, 0.7 parts by weight of carbon nanotube CNT, and 5 parts by weight of polyvinylidene fluoride, and add 100 parts by weight of N-N-dimethylpyrrolidone is stirred to form a slurry, which is evenly coated on the positive electrode-based fluid calendered aluminum foil with a thickness of 8 μm, and after drying, it is rolled by a roller compactor to make a positive electrode sheet.

[0029] Preparation of negative pole piece: Mix 90 parts by weight of lithium titanate, 1 part by weight of conductive carbon black SP, and 8 parts by weight of polyvinylidene fluoride, and add 110 parts by weight of N-N-dimethylpyrrolidone to form a slurry, uniform Coated on a 10 μm thick negative electrode-based fluid electrolytic copper foil, dried and rolled with a rolling machine to make a negative electrode sheet.

[0030] Negative electrode ...

Embodiment 2

[0037] Preparation of positive electrode sheet: mix 90 parts by weight of lithium cobaltate, nickel cobalt lithium manganate mixture (3:7), 2 parts by weight of conductive carbon black SP, 3 parts by weight of carbon nanotube CNT, and 6 parts by weight of poly Vinylidene fluoride, and add 100 parts by weight of N-N-dimethylpyrrolidone to stir to form a slurry, uniformly coated on the positive electrode-based fluid calendered aluminum foil with a thickness of 10 μm, and after drying, roll it with a roller compactor to make a positive electrode pole piece.

[0038] Preparation of negative pole piece: Mix 90 parts by weight of lithium titanate, 2.7 parts by weight of conductive carbon black SP, and 8 parts by weight of polyvinylidene fluoride, and add 110 parts by weight of N-N-dimethylpyrrolidone to form a slurry, uniform coated on a 6 μm thick negative electrode-based fluid electrolytic copper foil, and rolled with a rolling machine after drying to make a negative electrode she...

Embodiment 3

[0046] Prepare the positive electrode sheet: mix 90 parts by weight of lithium cobaltate, 2 parts by weight of conductive carbon black SP, 3 parts by weight of vapor-grown carbon fiber, and 6 parts by weight of polyvinylidene fluoride, and add 120 parts by weight of N-N-two The methylpyrrolidone was stirred to form a slurry, which was evenly coated on the calendered aluminum foil of the positive electrode base fluid with a thickness of 6 μm. After drying, it was rolled by a roller compactor to make the positive electrode sheet.

[0047] Preparation of negative pole piece: mix 90 parts by weight of lithium titanate, 2 parts by weight of conductive carbon black SP, 4 parts by weight of scaly graphite, and 8 parts by weight of polyvinylidene fluoride, and add 110 parts by weight of N-N-two The methyl pyrrolidone is stirred to form a slurry, which is evenly coated on the 6 μm thick negative electrode base fluid electrolytic copper foil, and after drying, it is rolled by a roller co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com