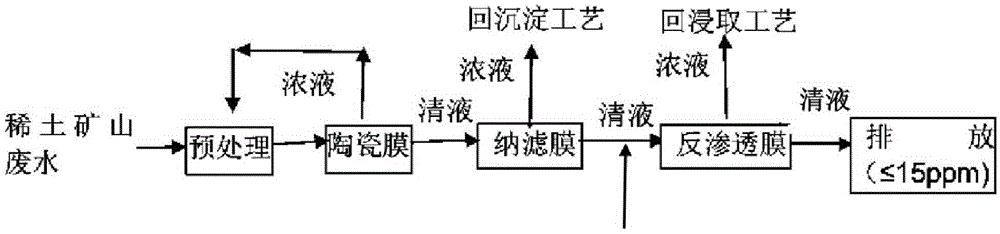

An ion-type rare earth mine wastewater membrane separation technology treatment method and device

A technology for ionic rare earth and mine wastewater, which is applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of ammonium sulfate cannot be recycled, waste of resources, and difficulty in rare earth wastewater treatment, so as to reduce Treatment cost, good effect, high retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

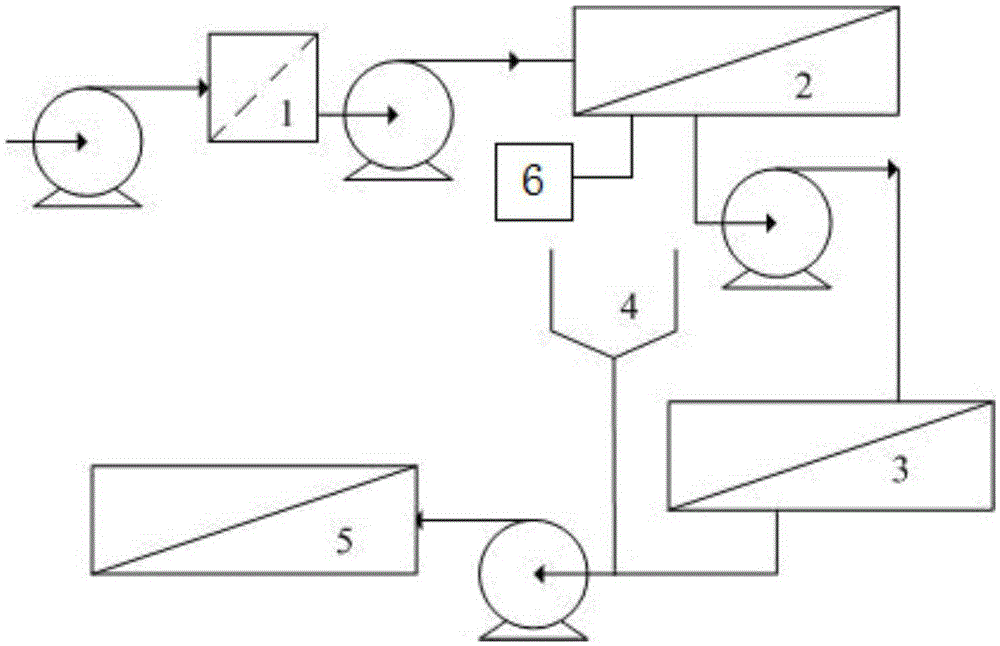

[0047] The ionic rare earth mine wastewater is pumped from the adjustment tank into the ceramic membrane equipment (the adjustment tank at this time also has a clarification function to remove large particles of solids) for removal and filtration of suspended solids. The ceramic membrane is controlled at a pressure of 0.2MPa, a flow velocity of 3m / s on the membrane surface, and a normal temperature. The material of the ceramic membrane is zirconia, and the average pore size is 0.2μm; The period is 30 minutes; the operation adopts continuous constant flow operation, and when the solid content in the dope reaches wt3%, constant concentration multiple filtration is carried out. The solid content of suspended solids in the clear liquid of the ceramic membrane is below 0.5NTU, which meets the requirements for entering nanofiltration membranes and reverse osmosis membranes.

[0048] The supernatant of the ceramic membrane is pumped into the nanofiltration membrane to separate the ra...

Embodiment 2

[0051] The ionic rare earth mine wastewater is pumped from the adjustment tank into the ceramic membrane equipment (the adjustment tank at this time also has a clarification function to remove large particles of solids) for removal and filtration of suspended solids. The ceramic membrane is controlled at a pressure of 0.2MPa, a flow velocity of 2m / s on the membrane surface, and a normal temperature. The material of the ceramic membrane is zirconia, and the average pore size is 0.05μm; The period is 45 minutes; the operation adopts continuous constant flow operation, and when the solid content in the dope reaches wt3.3%, constant concentration multiple filtration is carried out. The solid content of suspended solids in the clear liquid of the ceramic membrane is below 0.5NTU, which meets the requirements for entering nanofiltration membranes and reverse osmosis membranes.

[0052] The supernatant of the ceramic membrane is pumped into the nanofiltration membrane to separate the...

Embodiment 3

[0055] The ionic rare earth ore wastewater is pre-filtered through the quartz sand filter, and then enters the ceramic membrane equipment for removal and filtration of suspended solids. The ceramic membrane is controlled at a pressure of 0.2MPa, a membrane surface flow velocity of 2.5m / s, and a normal temperature. The material of the ceramic membrane is zirconia, and the average pore size is 0.05μm; the ceramic membrane has a timing recoil process, and the recoil time is 5s. The flushing period is 30 minutes; the operation adopts continuous constant flow operation, and when the solid content in the dope reaches wt3.8%, constant concentration multiple filtration (diafiltration) is carried out. The solid content of suspended solids in the clear liquid of the ceramic membrane is below 0.5NTU, which meets the requirements for entering nanofiltration membranes and reverse osmosis membranes.

[0056] The supernatant of the ceramic membrane is pumped into the nanofiltration membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com